Advertisement

Quick Links

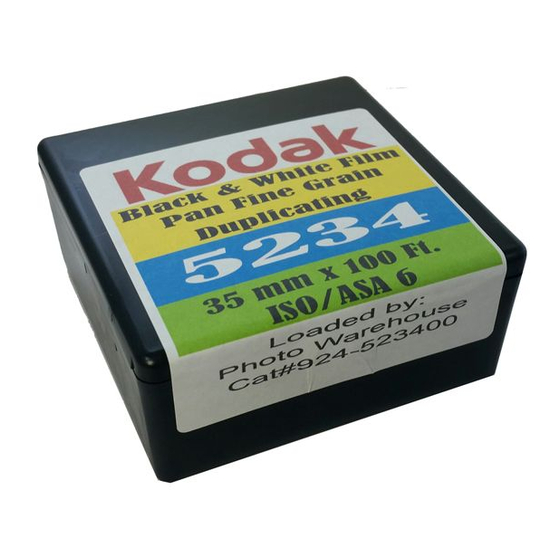

EASTMAN Fine Grain

Duplicating Panchromatic

Negative Film 5234, 7234

TECHNICAL DATA

EASTMAN Fine Grain Duplicating Panchromatic Negative

Film 5234/7234 is a panchromatic film characterized by

very high sharpness. This low-speed, black-and-white film

is designed for making duplicate negatives from master

positives, or internegatives from reversal originals. When

used with EASTMAN Fine Grain Duplicating Positive Film

5366/7366, it produces negatives nearly equal to the

original negative in tone rendering and printing detail.

BASE

5234/7234 Film has a gray acetate safety base. The back

side of the base contains an anti-static layer with a

carnauba wax lubricant.

DARKROOM RECOMMENDATIONS

Use a KODAK No. 3 Safelight Filter / dark green, with a

15-watt bulb, no closer to the film than 1.2 metres (4 feet).

STORAGE

Store unexposed film at 13°C (55°F) or lower. For extended

storage, store at -18°C (0°F) or lower. Process exposed film

promptly. Store processed film according to the

recommendations in ANSI/PIMA IT9.11-1998: for

medium-term storage (minimum of ten years), store at

25°C (77°F) or lower at a relative humidity of 20 to 50

percent; for extended-term storage (for preservation of

material having permanent value), store at 21°C (70°F) or

lower at a relative humidity of 20 to 30 percent. For active

use, store at 25°C (77°F) or lower, at a relative humidity of

50 +/- 5 percent. This relates to optimized film handling

rather than preservation; static, dust-attraction and

curl-related problems are generally minimized at the

higher relative humidity. After usage, the film should be

returned to the appropriate medium- or long-term storage

conditions as soon as possible.

For more information about medium- and long-term

storage, see ANSI/PIMA IT9.11-1998, SMPTE RP131-1998,

and KODAK Publications No. H-1, KODAK Motion Picture

Film, and No. H-23, The Book of Film Care.

©Eastman Kodak Company, 2013

PROCESSING

The following process recommendations should be used as

starting points for most conventional

continuous-immersion processors with solutions prepared

according to the formulas in KODAK Publication

No.H-24.15, Manual for Processing KODAK Motion Picture

Films, Module 15. The processing times may require

modification for a particular machine.

Note: Observe precautionary information on product

labels and on the Material Safety Data Sheets.

Processing Step

Temperature

KODAK

70 +-1/2 F

Developer

(21 +-0.3 C)

*

D-96

Stop Rinse

‡

70 +-2 F

(21 +-1 C)

KODAK Fixing

70 +-2 F

Bath

(21 +-1 C)

F-5

*

Wash

70 +-2 F

(counter-current)

(21 +-1 C)

Dry

95 F (35 C)

*

Agitation in the developer and fixing bath should be by recirculation through

submerged spray jets that impinge on the film strands.

†

Develop to recommended control gamma.

‡

Countercurrent flow of fixer-laden water overflow from the wash tank, pH

about 6.

¶

Many factors affect the drying: air temperature, relative humidity (RH);

volume, rate and distribution of the air flow; final squeegeeing, etc.

In a conventional convection-type drying cabinet with

air at about 95°F (35°C) and 40 to 50 percent RH, drying

will take 15 to 20 minutes. With an impingement-type

drying cabinet, however, with a higher temperature and

lower RH, drying time is greatly reduced. With either type

of dryer, the film should be dry without tackiness 1/2 to

2/3 of the way through. Upon cooling to room

temperature after leaving the dryer, the film should be in

equilibrium with the room air at approximately 50 percent

RH.

April 2013 • H-1-5234t

Time

Replenishment Rate

(mL per 100 ft)

35 mm

16 mm

1250

625

†

-

(D-96R)

(D-96R)

50 sec

12,000

6000

11 min

850

425

10 min

12,000

6000

¶

-

Advertisement

Summary of Contents for Kodak EASTMAN 5234

-

Page 1: Technical Data

† Developer (21 +-0.3 C) (D-96R) (D-96R) D-96 Use a KODAK No. 3 Safelight Filter / dark green, with a 15-watt bulb, no closer to the film than 1.2 metres (4 feet). Stop Rinse ‡ 70 +-2 F 50 sec... - Page 2 Base Density not apply directly to a particular box or roll of photographic material. They do not represent standards or specifications that must be met by Eastman Kodak Company. The F010_0020AC company reserves the right to change and improve LOG EXPOSURE (lux-seconds) product characteristics at any time.

- Page 3 MORE INFORMATION Outside the United States and Canada, please contact your Kodak representative. You can also visit our web site at www.kodak.com/go/motion for further information. You may want to bookmark our location so you can find us easily the next time.

Need help?

Do you have a question about the EASTMAN 5234 and is the answer not in the manual?

Questions and answers