Table of Contents

Advertisement

Quick Links

Operator Manual

Manuel de l'opérateur

Manual del operador

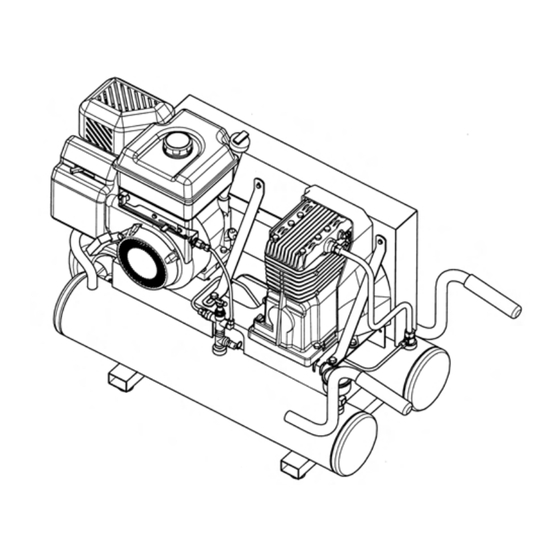

Single–Stage, Belt–Drive, Gasoline Engine Driven Air

Compressors

D'une seule étape, actionnement pour courroie, compresseurs d'air

motorisés d'essence

De una sola etapa, accionamiento por correa, compresores de aire

conducidos motor de la gasolina

WARNING: Read and understand all safety precautions in this manual before operating. Failure to comply with

instructions in this manual could result in personal injury, property damage, and/or voiding of your warranty.

Coleman Powermate Compressors WILL NOT be liable for any damage because of failure to follow these

instructions.

AVERTISSEMENT : Lire et s'assurer de bien comprendre toutes les consignes de sécurité du présent manuel

avant d'utiliser l'outil. Toute dérogation aux instructions contenues dans ce manuel peut entraîner l'annulation

de la garantie, causer des blessures et/ou des dommages matériels. Le fabricant NE SAURA être tenu

responsable de dommages résultant de l'inobservation de ces instructions.

ADVERTENCIA: Lea y comprenda todas las precauciones de seguridad contenidas en este manual antes de

utilizar esta herramienta. El no cumplir con las instrucciones de este manual podría dar como resultado la

anulación de su garantía, lesiones personales y/o daños a la propiedad. El fabricante NO SERA responsable de

cualquier daño debido a no acatar estas instrucciones.

© 2004 Coleman Powermate, Inc. P.O. Box 206, 118 West Rock Street, Springfield, MN 56087

Printed in U.S.A. 1-04

200-2358

Revision A

Advertisement

Table of Contents

Summary of Contents for Powermate 200-2358

- Page 1 WARNING: Read and understand all safety precautions in this manual before operating. Failure to comply with instructions in this manual could result in personal injury, property damage, and/or voiding of your warranty. Coleman Powermate Compressors WILL NOT be liable for any damage because of failure to follow these instructions.

-

Page 2: Table Of Contents

TABLE OF CONTENTS SAFETY GUIDELINES ......3 MAINTENANCE .......16 OVERVIEW . -

Page 3: Safety Guidelines

SAFETY GUIDELINES The following information relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the following symbols. Please read the manual and pay attention to these sections. – A POTENTIAL HAZARD THAT WILL CAUSE SERIOUS INJURY OR LOSS OF LIFE. DANGER: WARNING: –... -

Page 4: Consignes De Sécurité

CONSIGNES DE SÉCURITÉ Les informations suivantes concernent VOTRE SÉCURITÉ et LA PROTECTION DU MATÉRIEL CONTRE LES PANNES. Pour vous aider à identifier la nature de ces informations, nous utilisons les symboles suivants. Veuillez lire le manuel et prêter attention à ces sections. –... -

Page 5: Pautas De Seguridad

PAUTAS DE SEGURIDAD La información que sigue se refiere a la protección de SU SEGURIDAD y la PREVENCIÓN DE PROBLEMAS DEL EQUIPO. Como ayuda para reconocer esta información, usamos los siguientes símbolos. Lea por favor el manual y preste atención a estas secciones. PELIGRO: - UN POSIBLE RIESGO QUE CAUSARÁ... -

Page 6: Overview

OVERVIEW \ VUE D’ENSEMBLE \ RESUMEN GENERAL BASIC AIR COMPRESSOR COMPONENTS The basic components of the air compressor are the gasoline engine, pump, tank(s) and unloader. The gasoline engine (see A) powers the pump. The engine drives a pulley and belt, which transfers power from the engine to the pump pistons via a flywheel and a crankshaft. -

Page 7: Assembly

ASSEMBLY / ASSEMBLAGE / MONTAJE problèmes de lubrification, de mise en marche du moteur ASSEMBLING THE COMPRESSOR et de humidité d’eau gelée. Unpack the air compressor. Inspect the unit for damage. If Placez le compresseur sur le sol ou sur une surface dure the unit has been damaged in transit, contact the carrier and et horizontale. -

Page 8: Briggs & Stratton Muffler Installation

ASSEMBLY / ASSEMBLAGE / MONTAJE BRIGGS & STRATTON MUFFLER INSTALACIÓN DE SILENCIADOR DEL INSTALLATION BRIGGS & STRATTON WARNING: ADVERTENCIA: RISK OF FIRE OR EXPLOSION. RIESGO DE INCENDIO O Never operate the gasoline engine without the EXPLOSION. Nunca haga funcionar el motor de muffler properly installed;... -

Page 9: Compressor Controls

COMPRESSOR CONTROLS / COMMANDES DU COMPRESSEUR / CONTROLES DEL COMPRESOR COMPRESSOR CONTROLS Pressure Relief Valve (see A) This valve will pop open automatically to prevent overpressurization if the unloader does not switch the engine to idle when the tank pressure reaches the pre-set level. To operate manually, pull the ring on the valve to relieve air pressure in the tank(s). -

Page 10: Break-In Of The Pump

BREAK-IN OF THE PUMP \ RODAGE DE LA POMPE \ MARCHA DE LA BOMBA BREAK-IN OF THE PUMP A = Full - Plein - Lleno B = Add - Ajoutez - Agregor NOTE: When references are made to gasoline engine Screw-In Type Dipstick operations, refer to the engine manual for proper (Screw all the way in when... - Page 11 MARCHA DE LA BOMBA MARCHA INICIAL DE LA BOMBA A = Full - Plein - Lleno B = Add - Ajoutez - Agregor Antes de arrancar el compresor por primera vez, añada Screw-In Type Dipstick aceite al cárter del motor de gasolina. Consulte el manual (Screw all the way in when del motor sobre los requerimientos de aceite.

-

Page 12: Operating Instructions

Jauge de niveau d’huile vissée (Vissez fond pour la NOTE: The compressor pump is tested and shipped with vérification) Coleman Powermate SAE 10W30 all weather Varilla del tipo roscable compressor oil which is available thru your Coleman (Atornille completamente al Powermate dealer. -

Page 13: Instrucciones Operativas

(Atornille completamente al NOTA: La pompe de compresseur est testée et expédiée verificar) avec de l'huile tous temps de compresseur de Coleman Powermate SAE 10W30 qui est disponible Run position Start position par votre marchand de Coleman Powermate. Position de passage Position de début... -

Page 14: Cold Weather Starting

OPERATING INSTRUCTIONS \ MODE D’EMPLOI \ INSTRUCCIONES OPERATIVAS REMARQUE: Les modèles à deux réservoirs comportent COLD WEATHER STARTING deux robinets de purge. (Temperatures less than 32°F) Faites démarrer le moteur à essence conformément aux For the gasoline engine, cold weather preparation instructions contenues dans le manuel du moteur. -

Page 15: Shutdown

OPERATING INSTRUCTIONS \ MODE D’EMPLOI \ INSTRUCCIONES OPERATIVAS SHUTDOWN Shut off the gasoline engine(s). Reduce pressure in the tank(s) through the outlet hose. You can also pull the relief valve ring (see A) and keep it open to relieve pressure in the tank(s). CAUTION: Escaping air and moisture can propel debris that may cause eye injury. -

Page 16: Maintenance

MAINTENANCE \ ENTRETIEN \ MANTENIMIENTO MAINTENANCE VIDANGE D'HUILE WARNING: To avoid personal injury, always shut off Déposez le bouchon de l’orifice de vidange d’huile (voir A) the gasoline engine and relieve all air pressure from et vidangez l’huile jusqu’à ce que l’écoulement ralentisse et the system before performing any service on the air que l’huile ne fasse que s’égoutter. -

Page 17: Belt Tension And Pulley Alignment

MAINTENANCE \ ENTRETIEN \ MANTENIMIENTO BELT TENSION AND PULLEY ALIGNMENT WARNING: To avoid personal injury, always shut off the gasoline engine and relieve all air pressure from the system before performing any service on the air compressor. NOTE: Drive belt tensioning and pulley alignment are done at the same time. - Page 18 MAINTENANCE \ ENTRETIEN \ MANTENIMIENTO PULLEY ALIGNMENT To check pulley alignment, remove the belt guard and place a straightedge (see A) against the pump flywheel (see B). Measure and record the distance from the straightedge to the edge of the drive belt at point C. Then measure the distance from the straightedge to the edge of the drive belt again at points D and E.

-

Page 19: Cleaning The Air Filter

MAINTENANCE \ ENTRETIEN \ MANTENIMIENTO de la pompe et remplacez–la avec de l’huile neuve. Couvrez CLEANING THE AIR FILTER tout l’appareil pour le protéger contre l’humidité et la poussière. A dirty air filter will reduce the compressor’s performance and life. To avoid any internal contamination of the pump, the REMARQUE : Pour les procédures d’entreposage du filter should be cleaned frequently, and replaced on a regular... -

Page 20: Service Interval

SERVICE INTERVAL Perform the following maintenance at the intervals indicated below. Inspect and clean air filter ..........Daily Check pump oil level . -

Page 21: Troubleshooting Chart

TROUBLESHOOTING CHART Note: Troubleshooting problems may have similar causes and solutions. PROBLEM POSSIBLE CAUSE SOLUTION Low Discharge Pressure Air leaks Tighten or replace leaking fittings or connections. Do not overtighten. Leaking valves Contact authorized service center. Restricted air intake Clean or replace air filter element(s). Blown gaskets Contact authorized service center. -

Page 22: Dépannage

DÉPANNAGE Remarque : Les problémes de dépannage peuvent avoir des causes et des solutions similaires. PROBLÈME CAUSE POSSIBLE SOLUTION Pression de décharge insuffisante Fuites d’air Serrez ou remplacez les raccords ou les connexions qui ne sont pas étanches. Ne serrez pas trop. Fuites des soupapes Contactez le centre d’entretien agréé. -

Page 23: Cuadro De Deteccion De Fallos

CUADRO DE DETECCIÓN DE FALLOS Nota: Los problemas de deteccion de fallos pueden tener causas y soluciones similares. PROBLEMA CAUSA POSIBLE SOLUCION Baja presión de descarga Fugas de aire Ajuste o reemplace los accesorios o las conexiones con fugas. No ajuste demasiado. -

Page 24: Glossary Of Terms

GLOSSARY OF TERMS Well-ventilated Cubic feet per minute; a unit of measure of air flow. A means of providing fresh air in exchange for dangerous exhaust or vapors. Pounds per square inch; a unit of measure of air pressure. ASME American Society of Mechanical Engineers.

Need help?

Do you have a question about the 200-2358 and is the answer not in the manual?

Questions and answers