Table of Contents

Advertisement

Available languages

Available languages

Owner's Manual

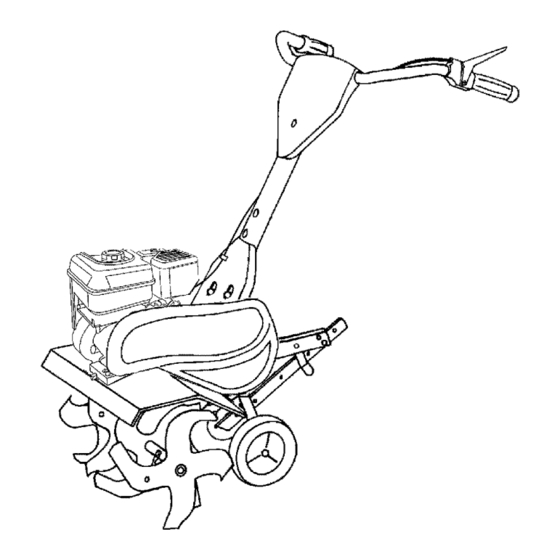

CRAFTSMAN +

FRONT TINE TILLER

5.5 HP

24 Inch Tine Width

Model No.

917.291490

• Espahol, p. 19

This product has a low emission engine which operates

I_

differently

from

previously

built engines.

Before

start the

you

engine, read and understand

this Owner's Manual,

IMPORTANT:

Read and follow all Safety

Rules and Instructions

before

operating this equipment.

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman

website:www.sears.com/craftsman

Advertisement

Table of Contents

Summary of Contents for Craftsman 917.291490

- Page 1 Before start the engine, read and understand this Owner's Manual, IMPORTANT: Read and follow all Safety Rules and Instructions before operating this equipment. Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A. Visit our Craftsman website:www.sears.com/craftsman...

- Page 2 • If this Craftsman Tiller is used for commercial or rental purposes, this Warranty plies for only thirty (30) days from the date of purchase. Warranty service...

- Page 3 • Use extensioncords and receptacles • Do not overload the machine capacity as specifiedby the manufacturerfor all by attempting to till too deep at too fast units with electricdrive motors or elec- a rate. tric starting motors. • Never operate the machine at high •...

- Page 4 (Gap: .030") RCl 2YC AGREEMENTS Congratulations on making a smart pur- CONGRATULATIONS on your purchase chase. Your new Craftsman® product is of a Sears Tiller. It has been designed, designed and manufactured for years of engineered and manufactured to give you dependable operation.

- Page 5 These accessories were available when the tiller was produced. They are also available at most Sears retail outlets and service centers. Some of these accessories may not apply to your tiller. ENGINE SPARK PLUG MUFFLER AIR FILTER GAS CAN ENGINE OIL STABILIZER TILLER MAINTENANCE BELT...

- Page 6 Your new tiller has been assembled at the factory with the exception of those parts left unassembled for shipping purposes. To ensure safe and proper operation of your tiller all parts and hardware you assemble must be tightened securely. Use the correct tools as necessary to insure...

- Page 7 KNOWYOUR TILLER READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATINGYOUR TILLER Compare the illustrations with your tiller to familiarize yourself with the locations of var- ious controls and adjustments. Save this manual for future reference. TILLING FORWARD NEUTRAL REVERSE CAUTION ENGINE ENGINE...

- Page 8 The operation of any tiller can result in foreign objects thrown into the eyes, which can result in severe eye damage. Always wear safety glasses or eye shields before starting your tiller and while tilling. We recommend standard safety glasses or a wide vision safety mask worn over spectacles.

- Page 9 4. Tilt tiller backon its wheels and then TO START ENGINE re-level. _CAUTION: Keep tine control in "OFF" 5. With enginelevel,refill to point of over- position when starting engine. flowingif necessary. Replaceoil filler When starting engine for the first time or plug.

- Page 10 BREAKING IN YOUR TILLER • You will find tilling much easier if you leave a row untilled between passes. Break-in your belt(s), pulleys and tine con- Then go back between tilled rows There trol before you actually begin tilling. are two reasons for doing this.

- Page 11 MAINTENANCE SCHEDULE zZ X@ FILL IN DATES SERVICE DATES AS YOU COMPLETE REGULAR SERVICE Check Engine Oil Level Change Engine Oil Oil Pivot Points Inspect Spark Arrester / Muffler Inspect Air Screen Clean or Replace Air Cleaner Cartridge Clean Engine Cylinder Fins Replace Spark Plug 1 - Change more often when operating under a heavy toad or in high ambient temperatures.

- Page 12 Al:_CAUTION:Disconnect spark plug Refill engine with oil. See "FILL ENGINE WITH OIL "in the Operation wire before performing any maintenance section of this manual. (except carburetor adjustment) to prevent accidental starting of engine. Prevent fires! Keep the engine free of grass, leaves, spilled...

- Page 13 COOLING SYSTEM SPARK PLUG Your engine is air cooled. For proper Replace spark plugs at the beginning gine performance and long life keep your each tilling season or after every 50 hours engine clean. of use, whichever comes first. Spark plug •...

- Page 14 MID-WIDTH TILLING - 22" PATH _CAUTION: Disconnect spark plug wire from spark plug and place wire where • Assemble holes "A" in tine hubs to holes cannot come into contact with plug. "C" in tine shaft. TILLER TO ADJUST HANDLE HEIGHT Factory assembly...

- Page 15 FINAL CHECK "ON" POSITION TO REPLACE V-BELT With tine control "ON" (held down to Replace V-belt if it has stretched consid- handle) push down on handle to raise erably or if it has cracks or frayed edges. tines off the ground. Belt guard must be removed to ser-...

- Page 16 Immediately prepare your tiller for storage NOTE: Fuel stabilizer is an acceptable at the end of the season or if the unit will alternative in minimizing the formation not be used for 30 days or more. fuel gum deposits during storage.

- Page 17 TROUBLESHOOTING CHART: See appropriate section in manual unless directed to Sears service center PROBLEM CAUSE CORRECTION Will not start 1. Out of fuel. Fill fuel tank. See "TO START ENGINE" Engine not "CHOKED" properly. in the Operation section. Wait several minutes before Engine...

- Page 18 TROUBLESHOOTING CHART: See appropriate section in manual unless directed to Sears service center CAUSE CORRECTION PROBLEM Engine Low oil level/dirty oil. 1. Check oil level/change oil. overheats Dirty engine air screen. Clean engine air screen. Dirty engine. Clean cylinder fins, airscreen, muffler area.

- Page 19 Programa De Mantenimiento ....... GARANTiA LIMtTADA DE UNO ANO PARA LA CULTtVADORA CRAFTSMAN Por un (1) ado, a partir de la fecha de compra, cuando esta Cultivadora Craftsman se mantenga, lubrique y afine segQn las instrucciones para la operacion y el mantenimiento en el manual del duedo, Sears reparara, gratis, todo defecto en el material y la mano de obra.

- Page 20 OPERACION • Use solamente accesorios y aditamentos para la cultivadora aprobados por el fabri- • No ponga ni las manos ni los pies cerca o cante. debajo de las piezas rotatorias. • Nunca opere la cultivadora sin buena visibili- • Tenga mucho cuidado cuando opere o cruce dad o luz.

- Page 21 PARA LA REPARACION Capacidad 3 Cuartos Congratulaciones por su buena compra. Gasolina: Sin plomo, Regular Su nuevo producto Craftsman® esta dise5ado Aceite (API-SG-SL): SAE 30 (Sobre 32°F) y fabricado para funcionar de modo fiable por (Capacidad: 20 oz.) SAE 5W-30 (Debajo 32°F)

- Page 22 Estos accesorios estaban disponibles cuando se produjo la cultivadora. Tambien estan disponibles en la mayoMa de las tiendas de Sears yen los centros de servicio. Algunos de estos accesorios tal vez no se apliquen a su cultivadora. MOTOR BUJiA SILENCIADOR FILTRO DE AIRE LATA...

- Page 23 Su cultivadora nueva ha sido montada en la fabrica, con la excepcion de aquellas partes que se dejaron sin montar por razones de envio. Para asegurarse que la cultivadora operara en forma segura y adecuada, todas las partes y los articulos de ferreteria que monte tienen que estar apre- tados en forma segura.

- Page 24 CONOZCA SU CULTIVADORA LEA ESTE MANUAL DEL DUENOY LAS REGLAS DE SEGURIDAD ANTES DE OPERAR SU CUTIVADORA Compare las ilustraciones con su cultivadora para familiarizarse con la ubicacion de los diversos controles y ajustes. Guarde este manual para referencia en el futuro. Estos simbolos pueden apareser sobre su cultivadora en la literatura proporcionada con el producto.

- Page 25 La operacion de cualquier cultivadora puede hacer que salten objetos extrafios dentro de sus ojos, Io que puede producir dafios graves en estos. Siempre use anteojos de seguridad o protecciones para los ojos antes de hacer arrancar su cultivadora o mientras este labrando con ella.

- Page 26 PARA HACER ARRANCAR EL MOTOR Con el motor nivelado, vuelva a Ilenarlo hasta el punto de derramarse, si es necesa- _PRECAUCl6N: Mantenga la barra de rio. Vuelva a colocar el tap6n del dep6sito control de la impulsi6n en la posici6n "DESEN- de relleno de aceite.

- Page 27 RODAJE DE SU CULTIVADORA • Va a descrubrir que el labrado se facilita si deja una fila sin labrar entre las pasadas. Use su(s) correa(s), las poleas y el control de Entonces vuelva de nuevo entre las filas de los brazos antes de empezar a labrar. cultivo.

- Page 28 PROGRAMA MANTENIMIENTO QUE COMPLETE SERVlCIO /'_-_'/O_'/O_'/O'_'/ FECHAS DE SERVlClO REGULAR Revisar el nivel del aceite del motor Cambiar el aceite del motor Aceitar los puntos de pivote Inspeccionar el supresor del silenciador Inspeccionar la rejilla de aire Limpiar/cambiar el cartucho del filtro de aire Limpiar las aletas...

- Page 29 Despues de que el aceite se haya drenado _(_PRECAUCl6N: Desconecte el alambre de completamente, vuelva a colocar el tap6n la bujia antes de dar mantenimiento (excepto del drenaje del aceite y aprietelo en forma por el ajuste del carburador) para evitar que el segura.

- Page 30 BUJiA Aletas del cilindor Cambie las bujias al comienzo de cada temporada de cultivo, o despues de 50 horas de uso, Io que suceda primero. El tipo de bujia y la abertura aparece en las "ESPEClFICAClONES DEL PRODUCTO" en .Caja del ventilador la pagina 21 de este manual.

- Page 31 CULTIVO/LABRADO ESTRECHO - PASO DE Si los brazos no rotan, el alambre interior del cable de control esta demasiado suelto. 12-3/4" Suelte la abrazadera del cable y empuje el • Remueva los brazos exteriores. cable hacia arriba para remover la soltura y vuelva a apretar la abrazadera.

- Page 32 PARA CAMBIAR LA CORREA V MOTOR Cambie la correa V si se ha estirado consid- El mantenimiento, la reparaci6n, o el reemplazo erablemente o si estg_partida o si los bordes de cualquier dispositivos o sistemas del control estan desgastados. de la emision, los cuales sean hechos al costo La protecci6n de la correa tiene que del cliente, pueden ser realizados por cualquier removerse para darle servicio a la correa.

- Page 33 AVlSO: El estabilizador de combustible es una Inmediatamente prepare su cultivadora para el almacenamiento al final de la temporada o si la alternativa aceptable para reducir a un minimo unidad no se va a usar por 30 dias o mas. la formaci6n de depositos de goma en el com- _PRECAUCl6N: Nunca almacene la cultiva-...

- Page 34 IDENTIFICACION DE PROBLEMAS: Vea la seccion apropiada en el manual a menos que este dirigido a un centro de servicio Sears, CORRECCION PROBLEMA CAUSA No arranca 1. Sin combustible. 1. Llene el estanque de combustible. 2. Motor sin la "ESTRANGU- 2.

- Page 35 IDENTIFICACION DE PROBLEMAS: Yea la seccion apropiada en el manual a menos que este dirigido a un centro de servicio Sears. CAUSA CORRECCION PROBLEMA El motor se 1. Revise el nivel del aceite/cambie 1. Nivel del aceite bajo/aceite calienta dem sucio.

- Page 36 TILLER - - MODEL NUMBER 917.291490 HANDLES KEY PART PART DESCRIPTION DESCRIPTION 137118X021 12000027 Ring, Clip Panel, Control 9266R 12000059 Retainer, Ring Grip, Handle 98000129 72010520 Bolt 5/16-18 x 2-1/2 Nut, Flange STD533107 73970500 Locknut, Flange 5/16-18 uric Bolt, Carriage 5/16-18 x 3/4 181476...

- Page 37 TILLER - - MODEL NUMBER 917,291490 BELT GUARD AND PULLEY ASSEMBLY " PART PART DESCRIPTION DESCRIPTION 23230506 Screw Set 5/16-18 x 3/8 Patch 12000028 Ring, Retainer 130812 Sheave, Engine 151223 Sheave, Transmisison 86777 Screw, Tap Hex Head 12000036 Ring, Klip 74610812 Bolt, Hex Head 1/2-20 x 3/4...

- Page 38 TILLER - - MODEL NUMBER 917,291490 WHEEL AND DEPTH STAKE ASSEMBLY -'13 wheel &stake KEY PART PART DESCRIPTION DESCRIPTION 9194R Pin, Clevis 5388J Spring, Stake 74760520 Bolt, Hex Head 5/16-18 x 1-1/4 121117X Bolt, Shoulder 9188R Wheel STD523107 Bolt, Hex Head 5/16-18 x 3/4 STD551037 Washer...

- Page 39 TILLER - - MODEL NUMBER 917,291490 TINE ASSEMBLY tine_ipb_3 KEY PART KEY PART DESCRIPTION DESCRIPTION 156926 156925 Tine, Outer, L.H. Tine, Outer, R.H. 4929H Pin, Clevis 3146R Retainer, Spring Zinc 156924 Tine, Inner, R.H. NOTE: All component dimensions given in U.S. 156923 Tine, Inner,...

- Page 40 TILLER - - MODEL NUMBER 917,291490 TRANSMISSION transmission KEY PART KEY PART DESCRIPTION DESCRIPTION 74760524 Bolt, Hex 5/16-18 x 1-1/2 Gr. 2 STD523732 19091412 Washer 9/32 x 7/8 x 12 Ga. Bolt, Fin, Hex 3/8-16 x 3-1/4 STD551037 Washer 13/32 x 13/16 x 11 19092016 Washer 9/32 x 1-1/4 x 16 Ga.

- Page 41 TILLER - - MODEL NUMBER 917.291490 DECALS KEY PART DESCRIPTION 166214 Decal, Logo 166215 Decal, Belt Guard Tine Shield 137539 Decal, Cntrl Pnl inst. 120431X Decal, Hand Placement 191914 Decal, Engine Oper. 162215 Decal, Tine Shield Warning 167156 Decal, Engine B&S Intek 171078 Decal,...

- Page 42 TILLER - - MODEL NUMBER 917.291490 ENGINE, BRIGGS & STRATTON -- MODEL NUMBER 126302,TYPE NO. 0416-E1 1034 1026 15A@ 718_...

- Page 43 TILLER - - MODEL NUMBER 917.291490 ENGINE, BRIGGS & STRATTON -- MODEL NUMBER 126302,TYPE NO. 0416-E1 365_ I633A 692 _ 276 _ 1171 276 _-_ ,77 C ARBURETOR GASKET ,63% 633A_ 425_ 121 CARBURETOR OVERHAUL KIT ..633A_ 104_ 127_ 633@ 358 ENGINE GASKET SET...

- Page 44 TILLER - - MODEL NUMBER 917.291490 ENGINE, BRIGGS & STRATTON -- MODEL NUMBER 126302,TYPE NO. 0416-E1 65 _ 592 ÷ 1211 689 _> 456 @ 1005 ]11329 1036 EMISSIONS LABEL REPLACEMENT ENGINE I 1095 VALVE GASKET SET 1070 868% 363_ 102_ 663 _ 209_...

- Page 45 TILLER - - MODEL NUMBER 917.291490 ENGINE, BRIGGS & STRATTON -- MODEL NUMBER 126302,TYPE NO. 0416-E1 PART PART DESCRIPTION DESCRIPTION 699510 Cylinder Assembly 699220 Screw (Fuel Tank) 299819 ,Seal-Oil (Magneto Side) 694543 Adjuster-Rocker 699486 Head-Cylinder 691278 Spring-Governor 698210 ,+Gasket-Cylinder Head 209A 692571 Spring-Governor...

- Page 46 TILLER - - MODEL NUMBER 917.291490 ENGINE, BRIGGS & STRATTON -- MODEL NUMBER 126302,TYPE NO. 0416-E1 PART DESCRIPTION 690959 Pin-Locating 692565 Gear-Timing 692564 Retainer-E Ring 692566 Gear-Idler 694258 Retainer 694544 Stud (Rocker Arm) 693583 Guard-Muffler 699203 Screw (Muffler Guard) 836A 699632 Screw (Muffler...

- Page 48 Your Home To purchase a protection agreement (U.S.A.) or maintenance agreement (Canada) on a product serviced by Sears: 1°800-827°6655 (U.S,A.) 1 o800o361 °6665 (Canada) Pars pedir servicio de reparaci6n Au Canada pour service en fran(_ais: a domicilio, y pars ordenar piezas: 1-800-LE-FOYER 1-888-SU-HOG_:_ sM (1-88G533-6937)

Need help?

Do you have a question about the 917.291490 and is the answer not in the manual?

Questions and answers