Table of Contents

Advertisement

Owner's Manual

I:RRFTXMRN"

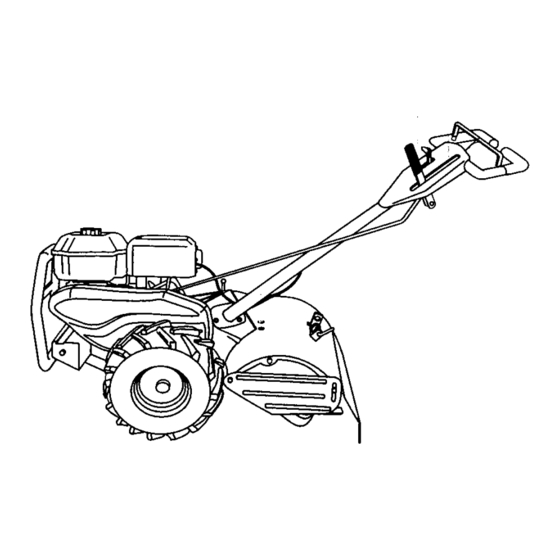

6.0 HP

17 INCH TINE WIDTH

REAR TINE WITH

COUNTER ROTATING TINE_

TILLER

Model No.

917.293311

• Safety

• Assembly

• Operation

• Maintenance

• Espa_ol

• Repair Parts

CAUTION:

Read and follow all Safety

Rules and Instructions before

operating this equipment.

For answers to your questions

about this product, Call:

1-800-659-5917

Sears Craftsman Help Line

5 am - 5 pro, Mon - Sat

Sears, Roebuck and Co., Hoffman Estates, II 60179

Visit our Craftsman

website:www.sears.com/craftsman

Advertisement

Table of Contents

Summary of Contents for Craftsman 917.293311

- Page 1 Call: Read and follow all Safety 1-800-659-5917 Rules and Instructions before operating this equipment. Sears Craftsman Help Line 5 am - 5 pro, Mon - Sat Sears, Roebuck and Co., Hoffman Estates, II 60179 Visit our Craftsman website:www.sears.com/craftsman...

- Page 2 • If this Craftsman Tiller is used for commercial or rental purposes, this Warranty applies for only thirty (30) days from the date of purchase.

- Page 3 Never operate the tiller without good • Never attempt to make any adjustments • visibility or light. while the engine (motor) is running Be careful when tilling in hard ground. (except where specifically recommend- • The tines may catch in the ground and ed by manufacturer).

-

Page 4: Maintenance

Owner's Manual. _kWARNING: This unit is equipped with Congratulations on your purchase of a an internal combustion engine and Craftsman Tiller. It has been designed, should not be used on or near any engineered and manufactured to give unimproved forest-covered,... -

Page 5: Tools Required For Assembly

Yournewtiller has been assembled at the front factory with exception of those parts left unassembled for shipping purposes. ensure safe and proper operation of your tiller all parts and hardware you assemble must be tightened securely. Use the correct tools as necessary to insure RIGHT LEFT... -

Page 6: Unpacking Carton

UNPACKING CARTON _kCAUTION: Be careful of exposed staples when handling or disposing "UP" Position cartoning material. Tighten handle IMPORTANT:When unpacking lock lever to hold assembling tiller, be careful not to stretch or kink cables. Loosen Handle Lock • While holding handle assembly, Lever to Move cable ties securing handle assembly top frame. - Page 7 INSERT CABLE CLIP Shift Lever Hairpin Indicator • Insert plastic cable clip into hole on the back of handle column. Push cables Shift Rod into clip. Handle Column Cables Cable Clip CONNECT SHIFT ROD REMOVE TILLER FROM CRATE • Insert end of shift rod farthest from bend •...

-

Page 8: Know Your Tiller

These symbols may appear on your Tiller or in literature supplied with the product. Learn and understand their meaning. KNOW YOUR TILLER READ THIS OWNER'S MANUALAND SAFETY RULES BEFORE OPERATING YOUR TILLER. Compare the illustrations with your tiller to familiarize yourself with the location various... - Page 9 The operation of any tiller can result in foreign objects thrown into the eyes, which can result in severe eye damage. Always wear safety glasses or eye shields before starting your tiller and while tilling. We recommend a wide vision safety mask over spectacles or standard safety glasses.

-

Page 10: Add Gasoline

TURNING CHECK ENGINE OIL LEVEL • Release the drive control bar. • The engine in your unit has been • Move throttle control to "SLOW" shipped, from the factory, already fUle¢ position. with SAE 30 summer weight oil. • Place shift lever indicator in "F" •... - Page 11 • Move throttle control to desired runnin! _I_CAUTION: Fill to within 1/2 inch of top position. of fuel tank to prevent spills and to allow • Allow engine to warm up for a few for fuel expansion. If gasoline is acciden- minutes before engaging tines.

- Page 12 o ol o olo O OI O OIO 2" O OI O OIO ;O O! O OIO ,CULTIVATING TINE SHEAR PINS Cultivating is destroying the weeds The tine assemblies on your tiller are between rows to prevent them from secured to the tine shaft with shear pins robbing nourishment and moisture from (See "FINE REPLACEMENT"...

-

Page 13: General Recommendations

SCHEDULE MAINTENANCE _/o_///_/_L =/_ / Check Engine Oil Level Change Engine Oil 1_1.21 Oil Pivot Points Inspect Spark Arrester / Muffler Inspect Air Screen Clean or Replace Air Cleaner Cartridge I_ 2 Clean Engine Cylinder Fins Replace Spark Plug RH Gear Case Grease Fitting (loz,) 1 - Change more often when operating ut_der a heavy load or in high ambient temperatures. -

Page 14: Air Filter

ACAUTION: Disconnect spark plug wire • Remove oil fill plug. before performing any maintenance • Refill engine with oil through oil fill (except carburetor adjustment) to prevent tube. See "CHECK ENGINE accidental starting of engine. LEVEL" in the Operation section of this manual. -

Page 15: Cooling System

MUFFLER Knob Do not operate tiller without muffler. Do r Cover_ tamper with exhaust system. Damaged mufflers or spark arresters could create fire hazard. Inspect periodically replace if necessary. If your engine is equipped with a spark arrester screen assembly, remove every 50 hours for cleaning... -

Page 16: Tire Care

TIRE CARE _Hex _IbCAUT|ON: When mounting tires, _F/_____ unless beads are seated, overinflation J_..._ Washer can cause an explosion. (Located • Maintain 20 pounds of tire pressure. _- ,'_" "_k Behind tire pressures are not equal, tiller will l\ Tire) pull to one side. -

Page 17: Tine Replacement

TINE REPLACEMENT • To maintain the superb tilling perfor- mance of this machine the tines shouk _I_CAUTION: Tines are sharp. Wear be checked for sharpness, wear, and gloves or other protection when handling bending, particularly the tines which tines. are next to the transmission. If the gap A badly worn tine causes your tiller to between... - Page 18 ENGINE TO ADJUST CARBURETOR Maintenance, repair, or replacement The carburetor has been preset at the the emission control devices and sys- factory and adjustment should not be tems, which are being done at the necessary. However, engine perfor- customers expense, may be performed mance can be affected by differences...

- Page 19 NOTE: Fuel stabilizer is an acceptable Immediately prepare your tiller for storage at the end of the season or if the unit will alternative in minimizing the formation fuel gum deposits during storage. not be used for 30 days or more. stabilizer to gasoline in fuel tank or...

- Page 20 CAUSE PROBLEM CORRECTION 1. Out of fuel. Will not start 1. Fill fuel tank. 2. See "TO START ENGINE" in 2. Engine not "CHOKED" properly. the Operation section. 3. Wait several minutes before 3. Engine flooded. attempting to start. 4. Dirty air cleaner, 4, Clean or replace air cleaner cartridge.

- Page 21 CAUSE CORRECTION PROBLEM Engine overheats 1. Check oil level/change oil. 1. Low oil level/dirty oil. 2. Dirty engine air screen. 2. Clean engine air screen. 3. Dirty engine. 3. Clean cylinder fins, air screer muffler area. 4. Remove and clean muffler, 4.

- Page 22 TILLER-- MODEL NUMBER 917,293311 HANDLES • • ,_'-.'_-a '_--_, "_;-S:-_._' KEY PART KEY PART DESCRIPTION DESCRIPTION 164743 Throttle, Control 19 19131611 Washer 13/32 x 1 x 11 Ga. 141406 109228)( Lever, Lock, Handle Grip, Handle 110673X Grommet, Handle 150258 Handle, Assemble 127254X Bar, Drive Control Assembly 165197...

- Page 23 TILLER -- MODEL NUMBER 917.293311 MAINFRAME, LEFT SIDE PART PART DESCRIPTION DESCRIPTION STD541031 *Nut, Hex 5/16-18 STD624003 *Clip,Hairpin STD551137 "Washer, Lock 3/8 165501X558 Guard, Belt STD54t037 *Nut, Hex 3/8-16 132801 Belt, V 170127 Shield, Inner Belt Guard 104679X Pulley, Idler 154734 Screw Shift Lever 12000032...

- Page 24 S'fD523107 14 S'rD541431 *Nut, Keps 5/16-18 Bolt, Hax 5/16-18 x 3/4 102332X Bracket, Reinforcement 15 ..Engine, (See Breakdown) STD523120 Craftsman Model No. Bolt, Hex 5/16-18 x 2 102173X 110402-0180-E1 CounterWeight, R,H. 16 7192J TieCable STD551137 *Washer, Lock 3/8 STD541037...

-

Page 25: Tiller Model 917.293311 Transmission

TILLER -- MODEL NUMBER 917.293311 TRANSMISSION 12,, 51 54 KEY PART PART DESCRIPTION DESCRIPTION 1 1_337 Transmission Assembly (Includes 143008 Beadng, Shaft, Ground Drive R.H. Key NOS.2-52) 106388X Spacer 0.70 x 1.00 x 1.150 165729 Gearcase, LH.w/Bearing 102121X Sprocket and Gear Assembly (Includes 102112X Shaft, Reduction (2nd) - Page 26 TILLER - - MODEL NUMBER 917.293311 TINE SHIELD PART PART DESCRIPTION DESCRIPTION 73900500 Nut, LockHexFlangeS/16*18UNC 19 102701X Grip 161415X558 Shield, Side, Outer L H. S'rD541037 *Nut, Hex 3/8-16 8393J Pin, Stake, Depth 102156X Stake, Depth 12000036 Ring, Klip 74930632 Bolt, Hex 3/8-16 x 2 STD533107 *Bolt, Carriage 5/16-18 x 3/4 Gr 5 23 4440J...

-

Page 27: Tine Assembly

TILLER - - MODEL NUMBER 917.293311 TINE ASSEMBLY PART PART DESCRIPTION DESCRIPTION 4459J Tine, Outer, L.H. 4460J Tine, Outer, R.H. 132673 Pin, Shear 10 132728 Assembly, Hub and Plate, R.H. 6554J Tine, lnner, L.H. 11 6555J Tine, Inner, R.H. 3146R *Clip,Hairpin *STANDARDHARDWARE--PURCHASELOCALLY 132727... - Page 28 120075X Decal, Wamiog, RotatingTines 10 163094 Dec, a t, Tine Depth Stake 11 162215 Decal, Tine, Shield, Wamlog Dora 12 166138 Decal, Engine 171076 Decal, Engine6HP REF 14 167156 Decal, Craftsman IC 15 171079 Decal, Rewind 172097 Manual, Owner's (Eng/Span)

- Page 29 TILLER - - MODEL NUMBER 917.293311 ENGINE, BRIGGS & STRATTON -- MODEL NUMBER 110402-0180-E1 718 _ REQUIRES SPECIAL TOOLS TO INSTALL SEE REPAIR INSTRUCTION MANUAL. 11010 LABEL KIT 27_ _ I lO66 O WNER'S MANUAL...

- Page 30 TILLER - - MODEL NUMBER 917.293311 ENGINE, BRIGGS & STRATTON - - MODEL NUMBER 110402-0180-E1 104" 692 II 108 l 276 @ 358 GASKET SET _ _/ 717 _,. 1022_ 5J _;_ 423A 868 _...

- Page 31 TILLER - - MODEL NUMBER 917.293311 ENGINE, BRIGGS & STRATTON - - MODEL NUMBER 110402-0180-E1 • _ 267 _._ 209A _.:, -_ 562 _" .,,,,,,,,,_265 _r_] I 1054 ,_,_ _ _T_' 663 ,_ 158 _t 621,_ , _i_i.-_, . :f 6161 615 836A I_ 832 i...

- Page 32 TILLER-- MODEL NUMBER 917.293311 ENGINE,BRIGGS& STRATTON - - MODEL NUMBER 110402-0180-E1 65 _P_ J 1036 EMISSIONS LABEL 363_ 4€1p 1005 lO44 305_ 1033 VALVE OVERHAUL KIT 1022...

- Page 33 TILLER -- MODEL NUMBER 917.293311 ENGINE, BRIGGS & STRATrON - - MODEL NUMBER 110402-0180-E1 KEY PART PART DESCRIPTION DESCRIPTION 693811 Cylinder Assembly 694112 Carburetor 399269 Bushing/Seal 223472 • Welch Plug 299819 Oil Seal 691181 Throttle Valve 693643 Cylinder Head 398187 Carburetor Float 273489 _r+ Cylinder Head Gasket...

- Page 34 TILt.ER - - MODEL NUMBER 917.293311 ENGINE, BRIGGS & STRATTON - - MODEL NUMBER 110402-0180-E1 KEY PART KEY PART NO. NO. DESCRIPTION NO. NO. DESCRIPTION 19374 Spark Plug Wrench 693583 Muffler Guard 693463 Oil Fill Plug 94896 Screw (Muffler Guard) 690349 Screw (Air Cleaner Base) 836A693624...

- Page 36 For in-home major brand repair service: Call 24 hours a day, 7 days a week 1-800-4-MY-HOME s" (1-800-469-4663) Para pedir servicio de reparaci6n a domicilio 1-800-676-5811 In Canada for all your service and parts needs call Au Canada pour tout le service ou les pi_ces 1-800-665-4455 For the repair or replacement parts you need: Call 6 am - 11 prn CST, 7 days a week...

Need help?

Do you have a question about the 917.293311 and is the answer not in the manual?

Questions and answers