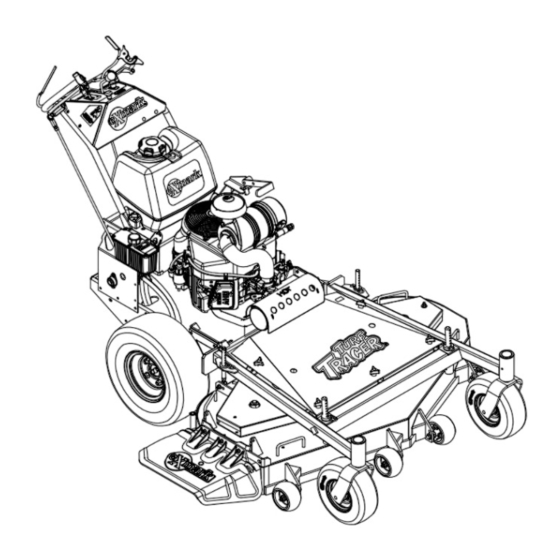

Exmark TURF TRACER Operator's Manual

Hide thumbs

Also See for TURF TRACER:

- Operator's manual (48 pages) ,

- Operator's manual (44 pages) ,

- Operator's manual (44 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Exmark TURF TRACER

- Page 1 TURF TRACER ® For Serial Nos. 850,000 & Higher Part No. 4500-528 Rev. B...

- Page 2 Replacements may be ordered through the engine manufacturer. Exmark reserves the right to make changes or add improvements to its products at any time without incurring any obligation to make such changes to products manufactured previously.

-

Page 3: Introduction

All Exmark parts are thoroughly tested and inspected before leaving the factory, however, attention is required on your part if you are to obtain the fullest measure of satisfaction and performance. -

Page 4: Table Of Contents

Contents Electric Clutch Adjustment......34 Cleaning ............34 Clean Grass Build-Up Under Deck ....34 Introduction ............3 Waste Disposal ..........34 Safety ..............5 Troubleshooting ........... 35 Safety Alert Symbol ......... 5 Schematics ............37 Safe Operating Practices ........5 Safety and Instructional Decals ..... -

Page 5: Safety

Only use accessories and DANGER: White lettering / Red background. attachments approved by Exmark. Indicates an imminently hazardous situation which, if • Wear appropriate clothing including safety glasses, not avoided, Will result in death or serious injury. - Page 6 Safety DANGER DANGER In certain conditions gasoline is extremely In certain conditions during fueling, static flammable and vapors are explosive. electricity can be released causing a spark which can ignite gasoline vapors. A fire or A fire or explosion from gasoline can burn explosion from gasoline can burn you and you, others, and cause property damage.

- Page 7 Safety Operation damage and make repairs before restarting and operating the mower). WARNING – Before clearing blockages. Operating engine parts, especially the muffler, – Whenever you leave the mower. become extremely hot. Severe burns can occur • Stop engine, wait for all moving parts to stop, and on contact and debris, such as leaves, grass, engage parking brake: brush, etc.

-

Page 8: Maintenance And Storage

Safety • Keep engine and engine area free from DANGER accumulation of grass, leaves, excessive grease Operating on wet grass or steep slopes can or oil, and other debris which can accumulate cause sliding and loss of control. Loss of control in these areas. - Page 9 Failure to use original Exmark parts could cause serious injury or death. Replace all parts including, but not limited to tires, belts, and blades with original Exmark...

-

Page 10: Safety And Instructional Decals

Exmark equipment dealer or labels. distributor or from Exmark Mfg. Co. Inc. • Replace all worn, damaged, or missing safety • Safety signs may be affixed by peeling off the signs. - Page 11 Safety 103–2242 103-2432 116-0404 103–2243 117–2718 103-4935...

-

Page 12: Specifications

• Capacity: 5.0 gal. (18.9 L) efficiency Parker wheel drive motors. • Type of Fuel: Regular unleaded gasoline, 87 • Hydraulic Oil: Use Exmark Premium Hydro Oil. octane or higher; containing no more than 10% • Hydraulic Oil Capacity: 2.4 qt. (2.2 L) methanol or ethanol. -

Page 13: Dimensions

Specifications Tires & Wheels Adjusts from 1 1/2 inches (3.8 cm) to 4 1/2 inches (11.4 cm) in 1/2 inch (1.3 cm) increments. Drive Front Caster • Mulching Kit: Optional Pneumatic Pneumatic Semi- • Bagger: Optional (Air-Filled) (Air-Filled) Pneumatic SN 599,999 SN 600,000 All Serial Dimensions... -

Page 14: Torque Requirements

Product Overview Torque Requirements Product Overview Bolt Location Torque Cutter Housing Spindle 140–145 ft-lb (190–197 N-m) Blade Mounting Bolt 55-60 ft-lb (75-81 N-m) (lubricate with anti-seize) 30-35 ft-lb (41-47 N-m) Engine Deck/Mower Deck Support Mount Bolts Type 1 Hardware 40-45 ft-lb (54-61 N-m) –Anti-Scalp Roller Whizlock Nut See Figure 9 Type 2... -

Page 15: Operation

Operation Operation as shown in Figure 4, and the drive levers are released, the drive wheels are engaged in the forward direction. Note: Determine the left and right sides of the Squeezing the left hand and/or right hand lever machine from the normal operating position. causes the left hand and/or right hand drive wheel respectively to slow down, stop, or reverse, depending on how far each drive lever is “squeezed”. -

Page 16: Pre-Start

Operation Drive Wheel Release Valves The brake lever engages the park brake on the drive wheels. Located on the left rear corner of the hydrostatic Pull the lever up and rearward to engage the brake. pumps. Drive wheel release valves are used to release the Push the lever forward and down to disengage the brake. -

Page 17: Operating Instructions

Operation Operating Instructions DANGER An uncovered discharge opening will allow Open the Fuel Shut-Off Valve objects to be thrown in an operator’s or bystander’s direction. Also, contact with the Rotate the valve 1/4 turn counterclockwise to turn blade could occur. Thrown objects or blade fuel on. -

Page 18: Driving The Machine

Operation Driving the Machine Driving Forward 1. Release the parking brake. Drive Lever/Neutral Lock Latch Operation 2. With drive levers locked in “neutral”, shift speed To lock the drive levers in “neutral lock”, squeeze the control lever to desired forward speed. drive levers to the “neutral”... -

Page 19: Adjusting The Cutting Height

Operation Adjusting the Cutting Height 6 7/8 inches) (175.01 mm) from the center of the balljoint to the center of the farthest hole. WARNING See Figure 7. When the two front support rod hairpins are Note: All four pins must equally support the removed from the mower deck, the weight of the weight of the deck. -

Page 20: Transporting

Operation maintain 1/4 inch (6.35 mm) clearance to ground. Do Not adjust rollers to support the deck. Be sure roller bolts are installed with the spring disc washer between head of the bolt and mounting bracket. Figure 9 Front left anti-scalp bracket shown 1. - Page 21 Operation Securely fasten the machine to the trailer with straps, chains, cables, or ropes. Do Not rely solely on the parking brake to hold the machine on the trailer. Be sure that the trailer has all necessary lighting and marking as required by law and use a safety chain.

-

Page 22: Maintenance

Maintenance Maintenance Note: Determine the left and right sides of the machine from the normal operating position. WARNING WARNING While maintenance or adjustments are being The engine can become very hot. Touching a hot made, someone could start the engine. engine can cause severe burns. -

Page 23: Periodic Maintenance

Maintenance Periodic Maintenance Important: Make sure the negative battery cable is disconnected and the battery charger used for charging the battery has an output of 16 volts and Check Engine Oil Level 7 amps or less to avoid damaging the battery (see chart for recommended charger settings). -

Page 24: Check Mower Blades

Maintenance 2. Make sure the booster is a good and fully charged lead acid battery at 12.6 volts or greater. Use properly sized jumper cables (4 to 6 AWG) with short lengths to reduce voltage drop between systems. Make sure the cables are color coded or labeled for the correct polarity. -

Page 25: Check Safety Interlock System

Note: If machine does not pass any of these tests, do not operate. Contact your authorized EXMARK SERVICE DEALER. Important: It is essential that operator safety mechanisms be connected and in proper... -

Page 26: Check For Loose Hardware

See the Engine manual for remove cap. Oil level should be to the top of the additional information.) baffle inside the tank. If not, add oil. Use Exmark Every 500 hours— Premium Hydro oil. Replace hydraulic reservoir Replace the secondary cap and tighten until snug. -

Page 27: Check Condition Of Belts

Maintenance Note: Front caster tires have permanent tire Lubrication Chart sealant installed. Fitting Initial Number of Service For Serial Nos. 600,000 and Higher: Locations Pumps Places Interval Semi-pneumatic caster tires do not need to be 4. Idler Yearly inflated. Pivot (Pump Note: Do Not add any type of tire liner or foam Drive) fill material to the tires. -

Page 28: Remove Engine Shrouds And Clean Cooling Fins

3. Make sure cooling shrouds are properly 7. Insert one bearing, one new seal into the wheel. reinstalled. Operating the engine without Note: Seals (Exmark P/N 103-0063) must be cooling shrouds will cause engine damage due to replaced. overheating. -

Page 29: Change Hydraulic System Filter

Mobil 1 15W50) jacks for support. Use adequate jack stands or equivalent support. Note: Use only Exmark Part No. 109-4180 for Summer use above 32°F (0°C) or P/N 1-523541 for 7. If either drive wheel does not rotate, one or both Winter use below 32°F (0°C) (Refer to Transmission... -

Page 30: Thread Locking Adhesives

Maintenance a steady flow of oil to flow out from under the housing. Retighten the capscrews. Do this for both pumps. Note: Hydraulic reservoir can be pressurized up to 5 psi to speed this process. 6. If either drive wheel still does not rotate, stop and repeat steps 4 and 5 above for the respective pump. -

Page 31: Mobil Hts Grease (Or Food-Grade Anti-Seize)

Maintenance Adjustments • OPC lever hubs and cross-shaft Note: Care must be used not to bond the Note: Disengage PTO, shut off engine, wait for bearing, next to each OPC hub, to the cross-shaft all moving parts to stop, engage parking brake, and which could cause binding of the OPC levers and remove key before servicing, cleaning, or making any erratic operation. - Page 32 Maintenance speed control linkage (see Figure 15) until the tabs are positioned correctly. Figure 15 Viewed from Left Side of Unit 1. Neutral Safety Switch 3. 5/16 inch (7.9 mm) Figure 16 2. Actuating Tab in neutral Viewed from Left Side of Unit position 1.

-

Page 33: Tracking Adjustment

Maintenance Note: The neutral lock latches should be to neutral. Recheck the drive wheel rotation “unlocked” and in the forward position. to see if further adjustment is necessary. 4. The spring that keeps tension on the knob 2. Loosen the front nut on left hydro control should normally not need adjustment. -

Page 34: Cleaning

Maintenance Cleaning 2. Check the drive tire pressures and tire circumferences as stated in Check the Tire Pressures section in Maintenance. Clean Grass Build-Up Under 3. Run the unit and observe the tracking on a level, Deck smooth, hard surface such as concrete or asphalt. 4. -

Page 35: Troubleshooting

Troubleshooting Troubleshooting Important: It is essential that all operator safety mechanisms be connected and in proper operating condition prior to mower use. When a problem occurs, do not overlook the simple causes. For example: starting problems could be caused by an empty fuel tank. The following table lists some of the common causes of trouble. - Page 36 Troubleshooting Problem Possible Cause Corrective Action Engine overheats 1. Engine load is excessive 1. Reduce the ground speed. 2. Oil level in the crankcase is low. 2. Add oil to the crankcase. 3. Cooling fins and air passages for the 3.

-

Page 37: Schematics

Schematics Schematics Electrical Diagram... - Page 38 Schematics Electrical Logic Schematic...

- Page 39 Schematics Hydraulic Diagram...

- Page 40 No Claim of breach of warranty shall be cause for cancellation or rescission of the contract of sale of any Exmark mower. All warranty work must be performed by an authorized Exmark Service Dealer using Exmark approved replacement All implied warranties of merchantability (that the parts.

-

Page 41: Service Record

Service Record Date: Description of Work Done: Service Done By:... - Page 43 Figure 20 This page may be copied for personal use. 1. The maximum slope you can safely operate the machine on is 20 degrees. Use the slope indicator to determine the degree of slope of hills before operating. Do Not operate this machine on a slope greater than 20 degrees. Fold along the appropriate line to match the recommended slope.

- Page 44 SEE EXMARK’S COMPLETE LINE OF ACCESSORIES AND OPTIONS MID-MOUNT RIDING ACCESSORIES AND OPTIONS CUSTOM RIDE SEAT SUSPENSION SYSTEM OPERATOR CONTROLLED DISCHARGE FULL SUSPENSION SEAT ROLL OVER PROTECTION SYSTEM (ROPS) DECK LIFT ASSIST KIT SUN SHADE HITCH KIT TRASH CONTAINER LIGHT KIT...

Need help?

Do you have a question about the TURF TRACER and is the answer not in the manual?

Questions and answers