Summary of Contents for Walrus Pump WQ200B

- Page 1 WQ_B Series Instruction Manual Electronic Control Pump Model: WQ200B / WQ400B / WQ800B To ensure safe and proper use, please read this instruction before operation. ISO 9001 Certified WALRUS PUMP CO., LTD.

-

Page 3: Operating Conditions

WQ_B Series Instruction Manual Before installing your new system, please study all instructions carefully, as the warranty does not cover failures caused by incorrect installation and operation. 1. Product The WQ_B series is designed to pump non-aggressive water or water not containing solid particles. - Page 4 4. Piping 4.1 The suction line should be installed as short and straight as possible, with a minimum of bends. The internal diameter of the suction pipe must be equal to or greater than the ports of the pump. 4.2 The connection between the suction line and pump must be airtight, and the suction pipe must be positioned, so it has an upward slope to the pump (thus avoiding the formation of air pockets).

- Page 5 5.2 Flooded Suction-from the city water supply. Water Main Home Supply Check Valve Isolation Valve Union Relief valve (Optional) Relief valve Pressure reducing valve To Drain Fig. 5 To Drain Check Valve Union Directly applied city pressure can exceed pump operating pressure and damage the pump.

- Page 6 7. Installation Guide This pump appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities or lack of experience and knowledge unless they have been given supervision or instruction concerning use of the pump appliance by a person responsible for their safety.

-

Page 7: Electrical Connection

8. Electrical Connection This mark located outside the connection box is an electrical hazard warning. 1. Ensure the mains voltage is the same as the value shown on the motor plate and that the pump is safely connected to the ground/earth. 9. -

Page 8: Operation And Service

11. Precautions 11.1 The pump should be shut down and the trouble corrected if the pump is running at speed and found to have any of the following problems: - No liquid discharged-Not enough liquid discharged. - Excessive vibration-Motor runs hot. 11.2 Do not allow the pump to continually start and stop (cycling) as this will reduce the motor life. - Page 9 13.2 Periodically check the condition of the check valve and strainer (if used). 13.3 If the pump is inactive for long periods, it should be rinsed thoroughly with clean water, then drained and stored in a dry place. It has to be re-primed before start-up. 13.4 If the pump shaft is seized up after periods of inactivity, please place a screwdriver from the motor end to rotate the shaft.

- Page 10 13.6 When the flanges are removed for maintenance or any reason, please follow the following instructions for installation: a. Place the gasket to the flanges Fig. 11 b. Install 4 screws to the flange and DO NOT tighten up at this time. When all 4 screws are in place, tighten them diagonally onto the flange.

-

Page 11: Noise Level

14. Flooded Suction Performance Table WQ200B Inlet pressure Flow rate (Kg/cm²) 11.4 Lpm 22.7 Lpm 34.1 Lpm 45.4 Lpm 56.8 Lpm WQ400B Inlet pressure Flow rate (Kg/cm²) 68.1 Lpm 79.5 Lpm 11.4 Lpm 22.7 Lpm 34.1 Lpm 45.4 Lpm 56.8 Lpm WQ800B Flow rate Inlet pressure... - Page 12 16.3 What is the purpose of the built-in pressure tank? The pressure tank comes from the factory pressurized at approximately 1.4-1.8 Kg/cm² (with the pump pressure at zero). It is designed to minimize motor startup due to small flow demand or minor leaks of the pipeline. WQ200B: 1.4 Kg/cm²...

-

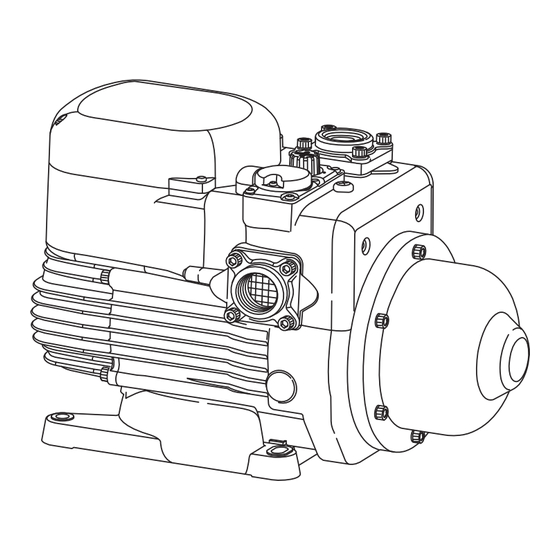

Page 13: Specification

17. Dimensions: (mm) WQ200B/WQ400B/WQ800B 18. Specification Cycle Dimensions(mm) Model ( Hz ) WQ200B WQ400B WQ800B ~ 12 ~... -

Page 14: Troubleshooting

18. Troubleshooting Before starting work on the pump, ensure that the electricity supply has been switched off and that it cannot be accidentally switched on. Cause Problem Remedy 1. Pump does not start a. No power supply Connect the electricity supply b. -

Page 15: Limited Warranty

Limited Warranty Products manufactured by Walrus Pumps Co (Walrus) are warranted to the first user only to be free of defects in material and workmanship for a period of 3 years from the date of installation, but no more than 24 months from the date of shipment. Walrus' liability under this warranty shall be limited to repairing or replacing at our election, without charge, FOB Walrus' distribution center or authorized service agent. - Page 16 WALRUS PUMP CO., LTD. walruspump.com...

Need help?

Do you have a question about the WQ200B and is the answer not in the manual?

Questions and answers