Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summarization of Contents

2. INSTALLATION INSTRUCTIONS, SAFETY AND HANDLING

General Installation Guidelines

Covers instructions, energy source, materials, corrosion, safety valves, noise, storage, and handling.

Electrical Connection Safety

Focuses on electrical connection, hot surfaces, high pressure/temperature warnings, and emergencies.

Transport and Tightening

Warning about transport damage and the importance of tightening connections.

Environmental and Safety Compliance

Information on REACH compliance, potential equalization, grounding, and disposal.

3. GETTING STARTED - QUICK GUIDE FOR EASY START-UP

Mounting Procedures

Instructions for mounting the substation securely on a solid wall.

Step-by-Step Start-up Guide

A quick guide outlining the initial setup steps, connections, and system checks.

4. Main Components and Connection Details

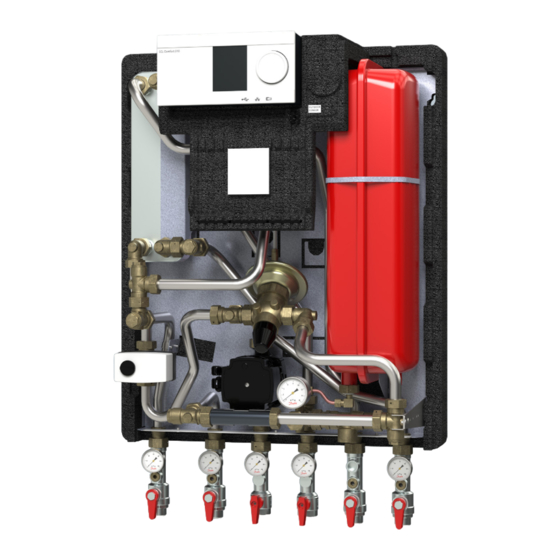

VXE H SOLO 310/A230 Components

Lists and illustrates the main components for the VXE H SOLO 310/A230 model.

VXE SOLO HWP ECL 310/A237 Components

Lists and illustrates the main components for the VXE SOLO HWP ECL 310/A237 model.

VXE SOLO HWP ECL 310/A247 Components

Lists and illustrates the main components for the VXE SOLO HWP ECL 310/A247 model.

VXE SOLO HWS ECL 310/A237 Components

Lists and illustrates the main components for the VXE SOLO HWS ECL 310/A237 model.

VXE SOLO HWS ECL 310/A347 Components

Lists and illustrates the main components for the VXE SOLO HWS ECL 310/A347 model.

VXE H OP ECL 310 Components

Lists and illustrates the main components for the VXE H OP ECL 310 model.

5. Diagram and Dimensional Sketch Examples

VXE SOLO H ECL310/A230 Diagram

Provides schematic diagram and dimensional sketch for VXE SOLO H ECL310/A230.

VXE SOLO HWP ECL 310/A237 Diagram

Provides schematic diagram and dimensional sketch for VXE SOLO HWP ECL 310/A237.

VXE SOLO HWP ECL 310/A247 Diagram

Provides schematic diagram and dimensional sketch for VXE SOLO HWP ECL 310/A247.

VXE SOLO HWS ECL 310/A237 Diagram

Provides schematic diagram and dimensional sketch for VXE SOLO HWS ECL 310/A237.

VXE SOLO HWS ECL 310/A347 Diagram

Provides schematic diagram and dimensional sketch for VXE SOLO HWS ECL 310/A347.

VXE H OP ECL 310 Diagram

Provides schematic diagram and dimensional sketch for VXE H OP ECL 310.

6. GENERAL, MOUNTING OF HEAT METER AND SAFETY VALVES

General Installation and Accessibility

Ensuring free access for maintenance and correct mounting procedures.

Insulated System Panel Removal

Instructions for removing the front insulation panel without tools.

Connection Testing and Tightening

Procedure for retightening connections before and after filling to prevent leaks.

Heat Meter Installation Details

Guidance on fitting pieces for heat meters and mounting sensors.

Meter Display and Safety Valve Setup

Location of meter display and proper setup for safety valve blow-off pipes.

7. FILLING THE SYSTEM WITH WATER

Pre-Filling Checks and Connections

Ensuring all connections are secure and system components are ready before filling.

System Filling Procedure

Steps for filling the heat exchanger and system, including pressure checks.

Refilling Advice

Note on using a refill hose and connecting outside the substation for refilling.

8. ELECTRICAL CONNECTION

Professional Electrical Setup

Requirements for safe electrical connection by a qualified electrician.

Outdoor Sensor Mounting

Guidance on optimal placement and mounting of the outdoor temperature sensor.

Controller and Sensor Wiring

Details on connecting cables for sensors and actuators to the ECL controller.

Accessing ECL Base Part

Procedure for accessing the ECL base part to connect external sensors.

9. ADJUSTMENT AND COMMISSIONING

General Information and Commissioning

Notes on model variations and general commissioning of the substation.

System Filling and Operating Pressure

Procedure for filling the system and checking the operating pressure.

Differential Pressure Controller Function

Explanation of the differential pressure controller and specific models (H, HWP, HWS).

10. HEATING CIRCUIT, DANFOSS ECL 310 AUTOMATICS

Weather-Compensated Heating Control

How the ECL controller manages heating supply temperature based on outdoor conditions.

ECL 310 Controller Setup

Instructions for initial setup, time/date setting, and heat curve configuration.

11. CONTROL OF HEATING CIRCUIT

Actuator and Valve Control (VXe Solo H)

Control mechanisms for VXe Solo H using AVQM and AMV actuators.

AMV Actuator Details

Information on AMV 150 and AMV 13 actuators, including manual override.

Actuator and Valve Control (VXe Solo HWP)

Control mechanisms for VXe Solo HWP using VS 2 and AMV actuators.

11. CONTROL OF HEATING CIRCUIT

Actuator and Valve Control (VXe Solo HWS)

Control mechanisms for VXe Solo HWS using AHQM/VMV and AMV actuators.

11. CONTROL OF HEATING CIRCUIT

Jumo AT Safety Thermostat Integration

Description of the Jumo AT safety thermostat for overheating protection.

12. HEATING CIRCUIT, PUMP

Grundfos UPM3 AUTO Pump Overview

Details on the Grundfos UPM3 AUTO pump, its user interface, and factory settings.

12. HEATING CIRCUIT, PUMP

Pump Setting Adjustment

Instructions for changing pump settings to optimize heat distribution.

Pump Alarm Status Interpretation

Understanding and troubleshooting pump alarm indicators.

13. DOMESTIC HOT WATER

DHW Connections for HWP/HWS Models

Details on domestic hot water cylinder connection pipes for HWP and HWS.

VXe Solo HWP DHW Control Diagrams

Diagrams illustrating DHW cylinder connection and control for VXe Solo HWP.

VXe Solo HWS DHW Control Diagrams

Diagrams illustrating DHW cylinder connection and control for VXe Solo HWS.

DHW Cylinder Circulation Pump Operation

Information on the DHW circulation pump and its control via sensor and ECL.

14. MAINTENANCE

General Maintenance Requirements

Overview of maintenance tasks to be performed by qualified personnel.

Inspection and Cleaning Procedures

Guidance on regular inspections, cleaning of strainers, and heat exchangers.

Post-Maintenance Checks

Essential checks after maintenance work, including connections and safety features.

Meter Reading and Temperature Monitoring

User tasks for meter reading and monitoring temperatures for energy efficiency.

14. MAINTENANCE SCHEDULE (recommendations)

Monthly Maintenance Recommendations

Tasks to perform monthly, including leak checks and connection verification.

Annual Maintenance Recommendations

Tasks to perform annually, including checks on pipes, insulation, and electrical safety.

15. TROUBLESHOOTING HE

Fundamental Troubleshooting Checks

Initial checks for power, system connections, and temperatures before troubleshooting.

No or Little Heat Issues

Troubleshooting steps for insufficient or absent heating output.

Heat Distribution Problems

Addressing uneven heat distribution and high/low supply temperatures.

Return Temperature and Noise Issues

Troubleshooting high DH return temperature, system noise, and heat load.

Product Disposal Guidelines

Instructions for dismantling and disposing of the product responsibly.

15. TROUBLE SHOOTING - DOMESTIC HOT WATER

Fundamental DHW Troubleshooting Checks

Initial checks for system connection and temperature before addressing DHW issues.

No or Little Hot Water Issues

Troubleshooting steps for lack of hot water or issues with water availability at taps.

DHW Temperature Control Issues

Addressing problems with high DHW temperature, declining temperature, or valve control.

DHW Capacity and No Hot Water

Troubleshooting capacity limitations and complete lack of DHW supply.

17. COMMISSIONING CERTIFICATE

Installer Commissioning Record

Section for the installer to record substation retightening, adjustment, and commissioning details.

18. GUIDELINES FOR WATER QUALITY IN DANFOSS BRAZED HEAT EXCHANGERS

Water Quality Parameters for Heat Exchangers

Guidelines for water quality parameters in stainless steel heat exchangers.

Chloride Concentration for SCC Prevention

Recommended chloride levels to avoid Stress Corrosion Cracking in stainless steel plates.

Need help?

Do you have a question about the ECL 310/A247 and is the answer not in the manual?

Questions and answers