Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Summary of Contents for HORA MC55/230

- Page 1 OPERATING MANUAL Linear actuators...

- Page 2 TABLE OF CONTENTS Operating manual MC55/24 · MC55/230 · MC55Y Operating manual MC100/24 · MC100/230 · MC103/24 · MC103/230 Operating manual MC160/24 · MC160/230 · MC161/24 · MC161/230 MC163/24 · MC163/230 Operating manual MC220/24 · MC220/230 · MC223/24 · MC223/230 Operating manual MC250/24 ·...

- Page 3 Operating Manual Linear actuators MC55/24 • MC55/230 • MC55Y November 2014 / 112476 / EN...

- Page 4 Manufacturer HORA Geschäftsbereich Flow Control Holter Regelarmaturen GmbH & Co. KG Helleforthstrasse 58–60 33758 Schloss Holte-Stukenbrock Germany phone: +49 (0) 5207/8903-0 mail: fc@hora.de www.hora.de Linear actuators MC55 Version 3.3 - November 2014 Operating Manual...

-

Page 5: Table Of Contents

Operating modes ............. 7 5 Commissioning............18 2.2.1 Continuous mode MC55Y ......7 Operating parameters and jumper settings....19 2.2.2 Three-point mode MC55/24, MC55/230 ..7 Setting the input signal for MC55Y......19 Functions ..............7 Setting the actuating time........19 2.3.1 Binary signal / frost protection function MC55Y Setting the actuating direction........20... -

Page 6: Safety

Hint: Utilisation instructions and other useful information. Proper use Linear actuators MC55/24, MC55/230, MC55Y are controlled by three-point control or constant control. Linear actuators in the series described in these Operating Instructions are used for valve stroke adjustment. Concurrence of the above type designation with the linear actuator rating plate must be checked prior to starting any operations in order to guarantee utilisation in accordance with specification. -

Page 7: Personnel

Prior to starting work Prior to starting any work, check that the type designations specified here concur with the data on the linear actuator rating plate. Linear actuators MC55/24, MC55/230, MC55Y. During operation Safe operation is only possible if transportation, storage, installation, operation and maintenance are carried out safely and materially and professionally correctly. -

Page 8: Product Specification

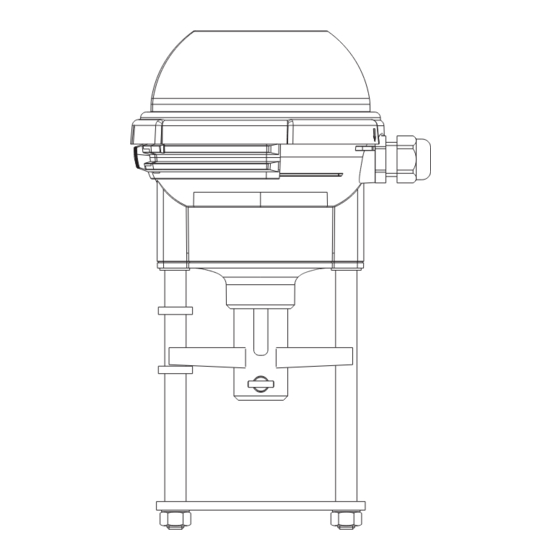

2 Product Specification 2 Product Specification The linear actuators control a stepper motor by means of a micro controller. The rotational movement of the stepper motor is converted into a linear movement by spur gears and a threaded spindle with spindle nut. Component parts 230 V 15.1... -

Page 9: Operating Modes

0% to 100% valve lift is put out as: • 0 … 10 V DC 2.2.2 Three-point mode MC55/24, MC55/230 The direction of rotation is set via the control voltage at terminal 2 and terminal 3 on the main PCB: •... -

Page 10: Blockage Detection

2 Product Specification 2.3.2 Blockage detection When the linear actuator is mechanically blocked the blockage detector will turn off the motor as soon as one of the two limit positions have been reached or a blockage occurs due to overload. 2.3.3 Wire break detection MC55Y Wire break detection is only available for continuous mode with an input signal... -

Page 11: Technical Data

2 Product Specification Technical data Type MC55/24, MC55Y MC55/230 Supply voltage: 24 V AC ± 10% 230 V AC + 6% -10% 24 V DC ± 10% 115 V AC ± 10% Power consumption 3,5 VA 7 VA Weight 1.5 kg 1.5 kg... -

Page 12: Type Plate

3 Transportation & Storage Type plate The type plate is attached to the housing of the linear actuator. It bears the type denomination, serial number (s/no) and date of manufacture (last four digits). 2.1 Component parts on page 6 MC55Y 08203017/01/0408 AC 50/60 Hz... -

Page 13: Assembly

4 Assembly 4 Assembly Prior to assembling the linear actuator: 4.1 Checking the scope of delivery on page 11 4.2 Preparing assembly on page 11 The following sequence of operations is part of the linear actuator assembly: 4.3 Mounting the linear actuator on the valve on page 12 ... -

Page 14: Mounting The Linear Actuator On The Valve

4 Assembly Mounting the linear actuator on the valve If the linear actuator and the valve are supplied separately you will have to mount the linear actuator on the valve. 7 mm Cross head 28 C-frame Clutch 34 Slide Valve 18 Valve stem 36 Hand wheel 19 Valve neck... -

Page 15: Assembling/Disassembling The Cover

4 Assembly Assembling/disassembling the cover Risk of injury from electric shock by live parts! When the power supply is on there is a danger of electric shock due to live parts. • Prior to commencing any work, ensure that the actuator is safely disconnected WARNING from the power supply system. -

Page 16: Electrical Connection

4 Assembly Electrical connection Danger of life caused by incompetent staff! Electrical connections carried out by unqualified staff may result in death, severe bodily injury or considerable material damage. WARNING • Make sure that such all work is carried out by qualified staff. ... - Page 17 4 Assembly 24 VAC / 24 VDC N (GND) UB N1 24 VAC / 230 VAC 24 VDC N (GND) N (GND) diagram 6 Circuit diagram Terminal Description UB, N1 Supply voltage: Control voltage for downward movement during three-point mode Control voltage for upward movement during three-point mode B1, B2 Binary input / frost protection function...

-

Page 18: Controller Independent Circuit Mc55Y

4 Assembly 4.5.1 Controller independent circuit MC55Y When working with 24 V supply voltage and 0 … 10 V DC / 2 … 10 V DC input signal you can switch the actuator controller-independently via a three-step toggle switch in the control cabinet. ... -

Page 19: Remove Push-Fit Pcb And Transformer

4 Assembly 4.5.2 Remove push-fit PCB and transformer MC55/230 To change settings you have to remove the push-fit PCB (107) on the 230 V model. Risk of injury from electric shock by live parts! When the power supply is on there is a danger of electric shock due to live parts. •... -

Page 20: Commissioning

4.4 Assembling/disassembling the cover on page 13 4.5.2 Remove push-fit PCB and transformer MC55/230 on page 17 24 V / 230 V 113 Plug-in jumper JP1-JP6 MC55Y 113 Plug-in jumper JP2-JP5 MC55/24, MC55/230 diagram 9 Plug-in jumper position on the main PCB Linear actuators MC55 Version 3.3 - November 2014... -

Page 21: Operating Parameters And Jumper Settings

Stroke Stroke curve curve Ready for operation table 5 Jumper settings MC55/24, MC55/230 Setting the input signal for MC55Y 0 ... 10 VDC 0 ... 20 mA 2 ... 10 VDC 4 ... 20 mA diagram 10 Setting the input signal ... -

Page 22: Setting The Actuating Direction

X = 10 V DC Y = 4 mA X = 0 V DC MC55Y Stroke Stroke Y, X Y, X MC55/24 Stroke Stroke MC55/230 table 6 Setting the actuating direction Linear actuators MC55 Version 3.3 - November 2014 Operating Manual... -

Page 23: Setting The Limit Position For Mc55Y

5 Commissioning Setting the limit position for MC55Y Use Jumper JP2 to select a limit position for the linear actuator. • JP2 ON: Limit position with extended spindle nut • JP2 OFF: Limit position with retracted spindle nut The limit position is approached in the following situations: •... -

Page 24: Operation

6 Operation 6 Operation Prior to commissioning the linear actuator you will have to select the operating mode. 5 Commissioning on page 18 Changing between manual and automatic mode It is possible to run the linear actuator in automatic mode or manual mode (manual adjustment). -

Page 25: Maintenance, Care And Repairs

7 Maintenance, care and repairs 7 Maintenance, care and repairs The linear actuator requires little maintenance. You do not have to carry our continuous or periodical maintenance. 8 Spare parts When ordering accessories and spare parts please quote the specifications engraved on the type plate of your linear actuator. -

Page 26: Check List For Breakdown

10 Removal of faults 10.2 Check list for breakdown Fault Cause/reason Remedy 1. Linear actuator is not Slide bar (34) in position manual mode Switch the slide bar to position automatic working. mode. Power cut Determine cause and remedy. Fuse defective (in control cabinet) ... - Page 27 Operating Manual Linear actuators MC100/24 • MC100/230 • MC103/24 • MC103/230 March 2011 / 112454 / EN...

- Page 28 Manufacturer HORA Geschäftsbereich Flow Control Holter Regelarmaturen GmbH & Co. KG Helleforthstrasse 58–60 33758 Schloss Holte-Stukenbrock Germany phone: +49 (0) 5207/8903-0 mail: fc@hora.de www.hora.de Linear actuators MC100 • MC103 Version 2.1 - March 2011 Operating Manual...

- Page 29 Table of contents Table of contents 1 Safety ................. 4 5 Commissioning............22 Proper use ............... 4 Operating parameters and encoding switch Information for the operator ........4 settings..............23 Personnel..............5 Setting the input signal...........23 Prior to starting work..........5 Setting the actuating time........23 During operation ............

-

Page 30: Safety

1 Safety 1 Safety Read these Operating Instructions carefully particularly the following safety instructions prior to installation and operation. DANGER Directly threatening hazard leading to death or serious physical injuries. DANGER WARNING Potentially hazardous situation which may lead to death or serious physical injuries. -

Page 31: Personnel

1 Safety Ensure that every person entrusted with one of the tasks specified in these Operating Instructions has read and understood these instructions. Personnel Only qualified personnel may work on these linear actuators or in their vicinity. Qualified persons are those persons entrusted with installation, assembly, commissioning and operation or maintenance of the linear actuators and possessing the appropriate qualifications for their activity. -

Page 32: Product Specification

2 Product Specification 2 Product Specification The linear actuators control a stepper motor by means of a micro controller. The stepper motor’s rotational movement is converted into a linear movement via planetary gears and a threaded spindle with spindle nut. Component parts MC100/24, MC103/24 7 mm... -

Page 33: Accessories

2 Product Specification Accessories 230 V 24 V 24 V AC / 24 V DC 230 V AC 111 PCB for output signal X = 0/4 ... 20 mA diagram 2 PCB for mA output signal in cover 230 V 24 V LED1 24 V AC / 24 V DC... -

Page 34: Three-Point Mode

2 Product Specification Input signal (Y) The input signal (Y) of the system control specifies the desired position for the linear actuator. It is applied in the form of an analogue signal to terminal Y. Possible input signals: • 0 … 10 V DC / 2 … 10 V DC •... -

Page 35: Actuating Time

2 Product Specification 2.4.4 Actuating time The time required for the spindle nut to travel a defined distance is called actuating time. Actuating time is specified in s/mm. Encoding switch S4 is used to set the actuating time. 5.3 Setting the actuating time on page 23 2.4.5 Hysteresis Hysteresis equals the difference of the input signal (Y) that is required after a... -

Page 36: Technical Data

2 Product Specification Technical data Type MC100/24, MC103/24 MC100/230, MC103/230 Supply voltage: 24 V AC ± 10% 115 V AC ± 10% 24 V DC ± 10% 230 V AC + 6% -10% Power consumption 6 VA 12 VA Weight 2.5 kg 2.5 kg Dimensions... -

Page 37: Type Plate

3 Transportation & Storage Type plate The type plate is attached to the housing of the linear actuator. It bears the type denomination, serial number (s/no) and date of manufacture (last four digits). 2.1 Component parts on page 6 MC100/24 F.-Nr.: 07204142/01/0607 AC 50 Hz 24 V... -

Page 38: Assembly

4 Assembly 4 Assembly Prior to assembling the linear actuator: 4.1 Checking the scope of delivery on page 12 4.2 Preparing assembly on page 12 The following sequence of operations is part of the linear actuator assembly: 4.3 Mounting the linear actuator on the valve on page 13 ... -

Page 39: Mounting The Linear Actuator On The Valve

4 Assembly Mounting the linear actuator on the valve If the linear actuator and the valve are supplied separately you will have to mount the linear actuator on the valve. Assembling MC100/24, MC100/230 Assembling MC103/24, MC103/230 Cross head 36 Hand wheel Adapter 51 Spacer ring Clutch... -

Page 40: Assembling/Disassembling The Cover

4 Assembly How to assemble linear actuator type MC103: Insert the C-frame (28). diagram 6 on page 13 Pull the adapter (3) off the clutch (6). Screw the hexagon locknut M10 (451) spanner width 17 onto the valve stem (18). -

Page 41: Electrical Connection

4 Assembly Damaged cables result in damage to devices! When lifting the cover you may tear off or damage the cabling inside the cover. • Carefully remove the cover. ATTENTION Remove the cover (201) carefully. Disconnect the plug-in connection between the main PCB and the (110) cover (201). - Page 42 4 Assembly How to establish electrical connection Remove the cover (201). How to remove the cover on page 14 Run the cable through the screw joint in the cover to the terminal. Connect the power supply according to the wiring diagram. diagram 8 ...

-

Page 43: Controller Independent Circuit

4 Assembly Terminal Description UB, N1 Supply voltage: Control voltage for downward movement during three-point mode Control voltage for upward movement during three-point mode Response signal during “manual” mode • R= 24 V DC max. 35 mA B1, B2 Binary input / frost protection function Zero potential of signals X, Y and R •... -

Page 44: Removing The Pcb Cover

4 Assembly 4.5.2 Removing the PCB cover To set the linear actuator by using the encoding switch you will first have to remove the PCB cover. (33) Risk of injury from electric shock by live parts! When the power supply is on there is a danger of electric shock due to live parts. •... -

Page 45: Fitting Accessories

4 Assembly Fitting accessories Accessories are not part of the scope of delivery for the linear actuator unless expressly ordered! The linear actuators are prepared for retro-fitting with: • PCB for path switch (106) • PCB for output signal X=0/4 … 20 mA (111) Hint: Optional operation with mA output signal or path switch possible ... -

Page 46: Fitting The Pcb For The Ma Output Signal

4 Assembly 123 Socket board diagram 12 Socket board for position switch PCB on main PCB Set the position switches. 5.8 Setting a potential-free path switch on page 25 4.6.2 Fitting the PCB for the mA output signal Risk of injury from electric shock by live parts! When the power supply is on there is a danger of electric shock due to live parts. - Page 47 4 Assembly 24 V 230 V 230 V 24 V 27 Spacers 115 Female plug 111 PCB for mA output signal 110 Main board 107 Push-fit PCB for 24 V or 230 V 201 Cover for 24 V or 230 V* diagram 13 Fitting a PCB for the mA output signal Push the female plug of the (115) PCB for the mA output signal onto the pin strip (123) of the main PCB (110) .

-

Page 48: Commissioning

5 Commissioning 5 Commissioning Risk of injury from electric shock by live parts! When the power supply is on there is a danger of electric shock due to live parts. • Prior to commencing any work, ensure that the actuator is safely disconnected WARNING from the power supply system. -

Page 49: Operating Parameters And Encoding Switch Settings

5 Commissioning Operating parameters and encoding switch settings Before starting to operate the linear actuator you will have to set the operating parameters with the help of the encoding switches and jumpers. Switch / jumper X-characteristic Stroke Stroke characteristic line line Y-characteristic Y-characteristic... -

Page 50: Setting The Hysteresis

5 Commissioning Setting the hysteresis 0.15 V 0.5 V diagram 19 Set hysteresis Additional information: 2.4.5 Hysteresis on page 9 Setting the actuating direction You can use the encoding switch (reverse operation) to reverse the actuating direction of the linear actuator. Actuator setting Normal operation Reverse operation (X and Y reversed) -

Page 51: Setting The Limit Position

5 Commissioning Setting the limit position Use encoding switch S6 to select the limit position for the linear actuator: • S6 ON: Limit position with extended spindle nut • S6 OFF: Limit position with retracted spindle nut The limit position is approached in the following situations: •... - Page 52 5 Commissioning 24 V LED1 LED1 LED2 LED2 230 V LED1 LED2 105 P1Trim-pot 105 P2Trim-pot diagram 20 Position switch PCB in cover Comply with the allowable contact load for the path switch: Nominal load 8 A, 250 V AC 8 A, 30 V DC Switch voltage max.

-

Page 53: Initialising The Path Measuring System

5 Commissioning Initialising the path measuring system Linear actuator starts automatically! The linear actuator starts immediately after being connected to the supply voltage and automatically moves to a reference point of the path measuring system. ATTENTION • Wait until this reference point has been reached and the linear actuator has stopped. -

Page 54: Commissioning

5 Commissioning 5.10 Commissioning Check whether all fitting and assembly work has been competently finished. 4 Assembly on page 12 Ensure that the electrical actuation of the linear actuator can take place safely without putting people or devices at risk. Ensure that the linear actuator is attached correctly and that the cover of the linear actuator is closed. -

Page 55: Operation

6 Operation 6 Operation Prior to commissioning the linear actuator you will have to initialise it and select the operating mode. 5 Commissioning on page 22 5.9 Initialising the path measuring system on page 27 Changing between manual and automatic mode It is possible to run the linear actuator in automatic mode or manual mode (manual adjustment). -

Page 56: Led Display

7 Maintenance, care and repairs LED display The LED on the main PCB in the actuator indicates the operating status or errors. 10.2 Check list for breakdown on page 32 Operating status / error Normal operation, ready for operation The LED is permanently lit, actuator waiting for traverse Duration command. -

Page 57: Decommissioning And Disposal

9 Decommissioning and disposal 9 Decommissioning and disposal Dispose of the linear actuator according to national regulations and laws. 10 Removal of faults After remedying faults you will have to re-initialise the path measuring system. 5.9 Initialising the path measuring system on page 27 10.1 How to remedy faults If the linear actuator does not work properly follow the sequence of operations... -

Page 58: Check List For Breakdown

10 Removal of faults 10.2 Check list for breakdown Fault Cause/reason Remedy 1. Linear actuator is not Hand wheel (36) is in position manual mode Switch hand wheel to position automatic working. mode. Power cut Determine cause and remedy. Fuse defective (in control cabinet) ... - Page 59 Operating Manual Linear actuators MC160/24 • MC160/230 • MC161/24 • MC161/230 MC163/24 • MC163/230 March 2011 / 108211 / EN...

- Page 60 Manufacturer HORA Geschäftsbereich Flow Control Holter Regelarmaturen GmbH & Co. KG Helleforthstrasse 58–60 33758 Schloss Holte-Stukenbrock Germany phone: +49 (0) 5207/8903-0 mail: fc@hora.de www.hora.de Linear actuators MC160 • MC161 • MC163 Version 2.1 - March 2011 Operating Manual...

- Page 61 Table of contents Table of contents 1 Safety ................. 4 5 Commissioning............24 Proper use ............... 4 Operating parameters and encoding switch Information for the operator ........4 settings..............25 Personnel..............5 Setting the input signal...........25 Prior to starting work..........5 Setting the actuating time........25 During operation ............

-

Page 62: Safety

1 Safety 1 Safety Read these Operating Instructions carefully particularly the following safety instructions prior to installation and operation. DANGER Directly threatening hazard leading to death or serious physical injuries. DANGER WARNING Potentially hazardous situation which may lead to death or serious physical injuries. -

Page 63: Personnel

1 Safety Ensure that every person entrusted with one of the tasks specified in these Operating Instructions has read and understood these instructions. Personnel Only qualified personnel may work on these linear actuators or in their vicinity. Qualified persons are those persons entrusted with installation, assembly, commissioning and operation or maintenance of the linear actuators and possessing the appropriate qualifications for their activity. -

Page 64: Product Specification

2 Product Specification 2 Product Specification The linear actuators control a stepper motor by means of a micro controller. The stepper motor’s rotational movement is converted into a linear movement via planetary gears and a threaded spindle with spindle nut. Component parts MC160/24, MC163/24 7 mm... -

Page 65: Accessories

2 Product Specification Accessories 230 V 24 V 24 V AC / 24 V DC 230 V AC 111 PCB for output signal X = 0/4 ... 20 mA diagram 2 PCB for mA output signal in cover 230 V 24 V LED1 24 V AC / 24 V DC... -

Page 66: Three-Point Mode

2 Product Specification Input signal (Y) The input signal (Y) of the system control specifies the desired position for the linear actuator. It is applied in the form of an analogue signal to terminal Y. Possible input signals: • 0 … 10 V DC / 2 … 10 V DC •... -

Page 67: Actuating Time

2 Product Specification 2.4.4 Actuating time The time required for the spindle nut to travel a defined distance is called actuating time. Actuating time is specified in s/mm. Encoding switch S4 is used to set the actuating time. 5.3 Setting the actuating time on page 25 2.4.5 Hysteresis Hysteresis equals the difference of the input signal (Y) that is required after a... -

Page 68: Technical Data

2 Product Specification Technical data Type MC160/24, MC161/24, MC160/230, MC161/230, MC163/24 MC163/230 Supply voltage: 24 V AC ± 10% 115 V AC ± 10% 24 V DC ± 10% 230 V AC + 6% -10% Power consumption 6 VA 12 VA Weight MC160 / MC161 = 3.2 kg MC160 / MC161 = 3.2 kg... -

Page 69: Type Plate

3 Transportation & Storage Type plate The type plate is attached to the housing of the linear actuator. It bears the type denomination, serial number (s/no) and date of manufacture (last four digits). 2.1 Component parts on page 6 MC160/24 F.-Nr.: 07204142/01/0607 AC 50 Hz 24 V... -

Page 70: Assembly

4 Assembly 4 Assembly Prior to assembling the linear actuator: 4.1 Checking the scope of delivery on page 12 4.2 Preparing assembly on page 12 The following sequence of operations is part of the linear actuator assembly: 4.3 Mounting the linear actuator on the valve on page 13 ... -

Page 71: Mounting The Linear Actuator On The Valve

4 Assembly Mounting the linear actuator on the valve If the linear actuator and the valve are supplied separately you will have to mount the linear actuator on the valve. Assembling MC160/24, MC160/230 Assembling MC161/24, MC161/230 Cross head 36 Hand wheel Coupling piece 51 Spacer ring 3.1 Adapter... - Page 72 4 Assembly Adjust the height of the spindle nut (5) with the help of the hand wheel (36) so that you can remount the bolt (315). Fit on the blank (314)! How to assemble linear actuator type MC161: Pull off the blank (314). ...

- Page 73 4 Assembly Assembling MC163/24, MC163/230 Cross head 51 Spacer ring Coupling piece 314 Blank Spindle nut 315 Bolt 18 Valve stem 451 Hexagon nut M10 19 Valve neck 459 Hexagonal nut 36 Hand wheel diagram 7 Mounting the linear actuator on the valve ...

-

Page 74: Assembling/Disassembling The Cover

4 Assembly Adjust the height of the spindle nut (5) with the help of the hand wheel (36) so that you can remount the bolt (315). Fit on the blank (314)! How to disassemble the linear actuator Follow the sequence of operation in reverse order. Assembling/disassembling the cover The cover contains the terminals for electric connection. -

Page 75: Electrical Connection

4 Assembly Hint: You can mount the cover (201) in four, different, positions each of which is transposed by 90°. This allows the best possible laying of the connecting cable for different installations of the linear actuator. Place the cover (201) on top and push it down to make it fit by applying moderate force. - Page 76 4 Assembly How to establish electrical connection Remove the cover (201). How to remove the cover on page 16 Run the cable through the screw joint in the cover to the terminal. Connect the power supply according to the wiring diagram. diagram 9 ...

-

Page 77: Controller Independent Circuit

4 Assembly Terminal Description UB, N1 Supply voltage: Control voltage for downward movement during three-point mode Control voltage for upward movement during three-point mode Response signal during “manual” mode • R= 24 V DC max. 35 mA B1, B2 Binary input / frost protection function Zero potential of signals X, Y and R •... -

Page 78: Removing The Pcb Cover

4 Assembly 4.5.2 Removing the PCB cover To set the linear actuator by using the encoding switch you will first have to remove the PCB cover. (33) Risk of injury from electric shock by live parts! When the power supply is on there is a danger of electric shock due to live parts. •... -

Page 79: Fitting Accessories

4 Assembly Fitting accessories Accessories are not part of the scope of delivery for the linear actuator unless expressly ordered! The linear actuators are prepared for retro-fitting with: • PCB for path switch (106) • PCB for output signal X=0/4 … 20 mA (111) Hint: Optional operation with mA output signal or path switch possible ... -

Page 80: Fitting The Pcb For The Ma Output Signal

4 Assembly 123 Socket board diagram 13 Socket board for position switch PCB on main PCB Set the position switches. 5.8 Setting a potential-free path switch on page 27 4.6.2 Fitting the PCB for the mA output signal Risk of injury from electric shock by live parts! When the power supply is on there is a danger of electric shock due to live parts. - Page 81 4 Assembly 24 V 230 V 230 V 24 V 27 Spacers 115 Female plug 111 PCB for mA output signal 110 Main board 107 Push-fit PCB for 24 V or 230 V 201 Cover for 24 V or 230 V diagram 14 Fitting a PCB for the mA output signal Push the female plug of the (115) PCB for the mA output signal onto the pin strip (123) of the main PCB (110) .

-

Page 82: Commissioning

5 Commissioning 5 Commissioning Risk of injury from electric shock by live parts! When the power supply is on there is a danger of electric shock due to live parts. • Prior to commencing any work, ensure that the actuator is safely disconnected WARNING from the power supply system. -

Page 83: Operating Parameters And Encoding Switch Settings

5 Commissioning Operating parameters and encoding switch settings Before starting to operate the linear actuator you will have to set the operating parameters with the help of the encoding switches and jumpers. Switch / jumper X-characteristic Stroke Stroke characteristic line line Y-characteristic Y-characteristic... -

Page 84: Setting The Hysteresis

5 Commissioning Setting the hysteresis 0.15 V 0.05 V 0.3 V 0.5 V diagram 20 Set hysteresis For further information see 2.4.5 Hysteresis on page 9 Setting the actuating direction You can use the encoding switch (reverse operation) to reverse the actuating direction of the linear actuator. -

Page 85: Setting The Limit Position

5 Commissioning Setting the limit position Use encoding switch S6 to select the limit position for the linear actuator: • S6 ON: Limit position with extended spindle nut • S6 OFF: Limit position with retracted spindle nut The limit position is approached in the following situations: •... - Page 86 5 Commissioning 24 V LED1 LED1 LED2 LED2 230 V LED1 LED2 105 P1Trim-pot 105 P2Trim-pot diagram 21 Position switch PCB in cover Comply with the allowable contact load for the path switch: Nominal load 8 A, 250 V AC 8 A, 30 V DC Switch voltage max.

-

Page 87: Initialising The Path Measuring System

5 Commissioning Initialising the path measuring system Linear actuator starts automatically! The linear actuator starts immediately after being connected to the supply voltage and automatically moves to a reference point of the path measuring system. ATTENTION • Wait until this reference point has been reached and the linear actuator has stopped. -

Page 88: Commissioning

5 Commissioning 5.10 Commissioning Check whether all fitting and assembly work has been competently finished. 4 Assembly on page 12 Ensure that the electrical actuation of the linear actuator can take place safely without putting people or devices at risk. Ensure that the linear actuator is attached correctly and that the cover of the linear actuator is closed. -

Page 89: Operation

6 Operation 6 Operation Prior to commissioning the linear actuator you will have to initialise it and select the operating mode. 5 Commissioning on page 24 5.9 Initialising the path measuring system on page 29 Changing between manual and automatic mode It is possible to run the linear actuator in automatic mode or manual mode (manual adjustment). -

Page 90: Led Display

7 Maintenance, care and repairs LED display The LED on the main PCB in the actuator indicates the operating status or errors. 10.2 Check list for breakdown on page 34 Operating status / error Normal operation, ready for operation The LED is permanently lit, actuator waiting for traverse Duration command. -

Page 91: Decommissioning And Disposal

9 Decommissioning and disposal 9 Decommissioning and disposal Dispose of the linear actuator according to national regulations and laws. 10 Removal of faults After remedying faults you will have to re-initialise the path measuring system. 5.9 Initialising the path measuring system on page 29 10.1 How to remedy faults If the linear actuator does not work properly follow the sequence of operations... -

Page 92: Check List For Breakdown

10 Removal of faults 10.2 Check list for breakdown Fault Cause/reason Remedy 1. Linear actuator is not Hand wheel (36) is in position manual mode Switch hand wheel to position automatic working. mode. Power cut Determine cause and remedy. Fuse defective (in control cabinet) ... - Page 93 Operating Manual Linear actuators MC220/24 • MC220/230 • MC223/24 • MC223/230 September 2021 / 358698 / EN...

- Page 94 Manufacturer HORA Geschäftsbereich Flow Control Holter Regelarmaturen GmbH & Co. KG Helleforthstrasse 58–60 33758 Schloss Holte-Stukenbrock Germany phone: +49 (0) 5207/8903-0 mail: fc@hora.de www.hora.de Linear actuators MC220 • MC223 Version 1.0 - September 2021 Operating Manual...

- Page 95 Table of contents Table of contents 1 Safety ................. 4 4 Assembly..............12 Proper use ............... 4 Checking the scope of delivery ......12 Information for the operator ........4 Preparing assembly ..........12 Personnel..............5 Mounting the linear actuator on the valve ....13 Prior to starting work..........

-

Page 96: Safety

1 Safety 1 Safety Read these Operating Instructions carefully particularly the following safety instructions prior to installation and operation. DANGER Directly threatening hazard leading to death or serious physical injuries. DANGER WARNING Potentially hazardous situation which may lead to death or serious physical injuries. -

Page 97: Personnel

1 Safety Ensure that every person entrusted with one of the tasks specified in these Operating Instructions has read and understood these instructions. Personnel Only qualified personnel may work on these linear actuators or in their vicinity. Qualified persons are those persons entrusted with installation, assembly, commissioning and operation or maintenance of the linear actuators and possessing the appropriate qualifications for their activity. -

Page 98: Product Specification

2 Product Specification 2 Product Specification The linear actuators control a stepper motor by means of a micro controller. The stepper motor’s rotational movement is converted into a linear movement via planetary gears and a threaded spindle with rotary gurad. Component parts MC220 MC223... -

Page 99: Accessories

2 Product Specification Accessories 230 V 24 V 24 VAC/ 24 V DC 230V AC 111 PCB for output signal X = 0/4 ... 20 mA diagram 2 PCB for mA output signal in cover 230 V 24 V 24V AC / 24V DC 230V AC LED1 LED1... -

Page 100: Three-Point Mode

2 Product Specification Input signal (Y) The input signal (Y) of the system control specifies the desired position for the linear actuator. It is applied in the form of an analogue signal to terminal Y. Possible input signals: • 0 … 10 V DC / 2 … 10 V DC •... -

Page 101: Actuating Time

2 Product Specification 2.4.4 Actuating time The time required for the rotary gurad to travel a defined distance is called actuating time. Actuating time is specified in s/mm. 2.4.5 Hysteresis Hysteresis equals the difference of the input signal (Y) that is required after a reversal of signal direction in order to move the rotary gurad. -

Page 102: Technical Data

2 Product Specification Technical data Type MC220/24, MC223/24 MC220/230, MC223/230 Supply voltage: 24 V AC ± 10% 115 V AC ± 10% 24 V DC ± 10% 230 V AC ± 10% Power consumption 6 VA 12 VA Weight MC220 = 3.2 kg MC220 = 3.2 kg MC223 = 4.0 kg MC223 = 4.0 kg... -

Page 103: Type Plate

3 Transportation & Storage Type plate The type plate is attached to the housing of the linear actuator. It bears the type denomination, serial number (s/no) and date of manufacture (last four digits). 2.1 Component parts on page 6 MC220/24 F.-Nr.: 07204142/01/0607 AC 50 Hz 24 V... -

Page 104: Assembly

4 Assembly 4 Assembly Prior to assembling the linear actuator: 4.1 Checking the scope of delivery on page 12 4.2 Preparing assembly on page 12 The following sequence of operations is part of the linear actuator assembly: 4.3 Mounting the linear actuator on the valve on page 13 ... -

Page 105: Mounting The Linear Actuator On The Valve

4 Assembly Mounting the linear actuator on the valve If the linear actuator and the valve are supplied separately you will have to mount the linear actuator on the valve. Assembling MC220/24, MC220/230 Cross head 308 Lock washers Coupling piece 314 Blank Rotary gurad 315 Bolt... - Page 106 4 Assembly Fix the valve stem (18) by the hexagon locknut (451), in order to prevent skewing. How to disassemble the linear actuator Follow the sequence of operation in reverse order. Assembling MC223/24, MC223/230 Cross head 312 Lock washers Coupling piece 314 Blank Rotary gurad...

-

Page 107: Assembling/Disassembling The Cover

4 Assembly Adjust the height of the rotary gurad (5) with the help of the hand wheel (36) so that you can remount the bolt (315). Fit on the blank (314)! Fix the valve stem (18) with the hexagon locknut (451), in order to prevent skewing. -

Page 108: Electrical Connection

4 Assembly Hint: You can mount the cover (201) in four, different, positions each of which is transposed by 90°. This allows the best possible laying of the connecting cable for different installations of the linear actuator. Place the cover (201) on top and push it down to make it fit by applying moderate force. - Page 109 4 Assembly How to establish electrical connection Remove the cover (201). How to remove the cover on page 15 Run the cable through the screw joint in the cover to the terminal. Connect the power supply according to the wiring diagram. ...

-

Page 110: Controller Independent Circuit

4 Assembly Terminal Description UB, N1 Supply voltage: Control voltage for downward movement during three-point mode Control voltage for upward movement during three-point mode Response signal during “manual” mode • R= 24 V DC max. 35 mA B1, B2 Binary input / frost protection function Zero potential of signals X, Y and R •... -

Page 111: Removing The Pcb Cover

4 Assembly 4.5.2 Removing the PCB cover To set the linear actuator by using the encoding switch you will first have to remove the PCB cover. (33) Risk of injury from electric shock by live parts! When the power supply is on there is a danger of electric shock due to live parts. •... -

Page 112: Fitting Accessories

4 Assembly Fitting accessories Accessories are not part of the scope of delivery for the linear actuator unless expressly ordered! The linear actuators are prepared for retro-fitting with: • PCB for path switch (106) • PCB for output signal X=0/4 … 20 mA (111) Hint: Optional operation with mA output signal or path switch possible ... -

Page 113: Fitting The Pcb For The Ma Output Signal

4 Assembly 123 Socket board diagram 13 Socket board for position switch PCB on main PCB Set the position switches. 5.7 Setting a potential-free path switch on page 26 4.6.2 Fitting the PCB for the mA output signal Risk of injury from electric shock by live parts! When the power supply is on there is a danger of electric shock due to live parts. - Page 114 4 Assembly 24 V 230 V 27 Spacers 115 Female plug 111 PCB for mA output signal 110 Main board 107 Push-fit PCB for 24 V or 230 V 201 Cover for 24 V or 230 V diagram 14 Fitting a PCB for the mA output signal Push the female plug of the (115) PCB for the mA output signal onto the pin strip (123) of the main PCB (110) .

-

Page 115: Commissioning

5 Commissioning 5 Commissioning Risk of injury from electric shock by live parts! When the power supply is on there is a danger of electric shock due to live parts. • Prior to commencing any work, ensure that the actuator is safely disconnected WARNING from the power supply system. -

Page 116: Operating Parameters And Encoding Switch Settings

5 Commissioning Operating parameters and encoding switch settings Before starting to operate the linear actuator you will have to set the operating parameters with the help of the encoding switches and jumpers. Switch / jumper X-characteristic Stroke Stroke characteristic line line Y-characteristic Y-characteristic... -

Page 117: Setting Auto Test And Auto Pause

5 Commissioning Actuator setting Normal operation Reverse operation (X and Y reversed) Y = 10 V DC Y = 0 V DC Y = 20 mA Y = 2 V DC Y = 0 mA Y = 4 mA Y = 0 V DC Y = 10 V DC Y = 2 V DC Y = 20 mA... -

Page 118: Setting The Limit Position

5 Commissioning Setting the limit position Use encoding switch S6 to select the limit position for the linear actuator: • S6 ON: Limit position with extended rotary gurad • S6 OFF: Limit position with retracted rotary gurad The limit position is approached in the following situations: •... - Page 119 5 Commissioning 24 V LED1 LED1 LED2 LED2 230 V LED1 LED2 105 P1Trim-pot 105 P2Trim-pot diagram 20 Position switch PCB in cover Comply with the allowable contact load for the path switch: Nominal load 8 A, 250 V AC 8 A, 30 V DC Switch voltage max.

-

Page 120: Initialising The Path Measuring System

5 Commissioning Initialising the path measuring system Linear actuator starts automatically! The linear actuator starts immediately after being connected to the supply voltage ATTENTION and automatically moves to a reference point of the path measuring system. • Wait until this reference point has been reached and the linear actuator has stopped. - Page 121 5 Commissioning Commissioning Check whether all fitting and assembly work has been competently finished. 4 Assembly on page 12 Ensure that the electrical actuation of the linear actuator can take place safely without putting people or devices at risk. Ensure that the linear actuator is attached correctly and that the cover of the linear actuator is closed.

-

Page 122: Commissioning

6 Operation 6 Operation Prior to commissioning the linear actuator you will have to initialise it and select the operating mode. 5 Commissioning on page 23 5.8 Initialising the path measuring system on page 28 Changing between manual and automatic mode It is possible to run the linear actuator in automatic mode or manual mode (manual adjustment). -

Page 123: Led Display

7 Maintenance, care and repairs LED display The LED on the main PCB in the actuator indicates the operating status or errors. 10.2 Check list for breakdown on page 33 Operating status / error Normal operation, ready for operation The LED is permanently lit, actuator waiting for traverse Duration command. -

Page 124: Decommissioning And Disposal

9 Decommissioning and disposal 9 Decommissioning and disposal Dispose of the linear actuator according to national regulations and laws. 10 Removal of faults After remedying faults you will have to re-initialise the path measuring system. 5.8 Initialising the path measuring system on page 28 10.1 How to remedy faults If the linear actuator does not work properly follow the sequence of operations... -

Page 125: Check List For Breakdown

10 Removal of faults 10.2 Check list for breakdown Fault Cause/reason Remedy 1. Linear actuator is not Hand wheel (36) is in position manual mode Switch hand wheel to position automatic working. mode. Power cut Determine cause and remedy. Fuse defective (in control cabinet) ... - Page 126 10 Removal of faults Linear actuators MC220 • MC223 Version 1.0 - September 2021 Operating Manual...

- Page 127 10 Removal of faults Linear actuators MC220 • MC223 Operating Manual Version 1.0 - September 2021...

- Page 128 HORA Geschäftsbereich Flow Control Holter Regelarmaturen GmbH & Co. KG Helleforthstrasse 58–60 33758 Schloss Holte-Stukenbrock Germany phone: +49 (0) 5207/8903-0 mail: fc@hora.de www.hora.de...

- Page 129 Operating Manual Linear Actuators MC250/24 • MC250/230 • MC253/24 • MC253/230 MC500/24 • MC500/230 • MC503/24 • MC503/230 March 2011 / 317371 / EN...

- Page 130 Manufacturer HORA Geschäftsbereich Flow Control Holter Regelarmaturen GmbH & Co. KG Helleforthstrasse 58–60 33758 Schloss Holte-Stukenbrock Germany phone: +49 (0) 5207/8903-0 mail: fc@hora.de www.hora.de Linear actuators MC250 • MC253 • MC500 • MC503 Version 2.1 - March 2011 Operating Manual...

- Page 131 Content Content 1 Safety ................. 4 5 Commissioning............22 Proper use ............... 4 Operating parameters and coding switch Information for the operator ........4 positions ..............22 Personnel..............5 Set input signal............23 Prior to starting work..........5 Set actuating time ..........23 During operation ............5 Set hysteresis............24 Working environment..........

-

Page 132: Safety

1 Safety 1 Safety Read these Operating Instructions carefully particularly the following safety instructions prior to installation and operation. DANGER Directly threatening hazard leading to death or serious physical injuries. DANGER WARNING Potentially hazardous situation which may lead to death or serious physical injuries. -

Page 133: Personnel

1 Safety Ensure that every person entrusted with one of the tasks specified in these Operating Instructions has read and understood these instructions. Personnel Only qualified personnel may work on these linear actuators or in their vicinity. Qualified persons are those persons entrusted with installation, assembly, commissioning and operation or maintenance of the linear actuators and possessing the appropriate qualifications for their activity. -

Page 134: Product Specification

2 Product Specification 2 Product Specification The linear actuator controls a step motor with the aid of a microcontroller. The rotational motion of the step motor is transformed into a linear motion via a planetary gearbox and a leadscrew with spindle nut. Components 230;... -

Page 135: Accessories

2 Product Specification Accessories 0...20 mA 4...20 mA 111 Printed circuit board for output signal X=0/4 … 20 mA Diagram 2 Printed circuit board for mA output signal on the motherboard LED1 LED2 LED1 LED2 106 Way-switch printed circuit board Diagram 3 Way-switch printed circuit board in cover Operating modes... -

Page 136: Three-Point Mode

2 Product Specification Input signal (Y) The input signal (Y) from the system control specifies the reference position for the linear actuator. It is an analogue signal on terminal Y. The following input signals are possible: • 0 … 10 V DC / 2 … 10 V DC •... -

Page 137: Open-Circuit Detection

2 Product Specification Actuator heating If the temperature in the actuator drops below 15 °C, the motor is switched to heating in the operating pauses. The actuator heating switches off automatically at a constant temperature of approx. 22 °C. The actuator heating does not affect the functions of the actuator. -

Page 138: Autotest

2 Product Specification 2.4.8 Autotest If a valve is not actuated over a long period, the valve cone may seize. The Autotest function prevents this. If the Autotest function of the linear actuator is switched on, the linear actuator moves after approx.10 days without actuation automatically in rapid traverse to the limit position set by coding switch S7 and returns to the starting position. -

Page 139: Ratingplate

3 Transport and storage Input signal Y/ • 0 … 10 V DC / 77 k Input resistor (resistance • 2 … 10 V DC / 77 k of load) • 0 … 20 mA / 510 ... -

Page 140: Assembly

4 Assembly 4 Assembly Prior to installation of the linear actuator: 4.1 Check the scope of supply on page 12 4.2 Prepare for installation on page 12 Installation of the linear actuator includes the following tasks: 4.3 Mount linear actuator on valve on page 13 ... -

Page 141: Mount Linear Actuator On Valve

4 Assembly Mount linear actuator on valve If the linear actuator und the valve are delivered separately, the linear actuator must then be mounted on the valve. Assembly of MC250/24, MC250/230, Assembly of MC253/24, MC253/230, MC500/24 and MC500/230 MC503/24 and MC503/230 Cross head 308 Retaining washers Coupling piece... -

Page 142: Fit/Remove Cover

4 Assembly Rotate the hexagonal nut M10 (451) wrench size 17 onto the valve spindle (18). Rotate the coupling (3) onto the valve spindle (18). Use the flat hexagonal nut to lock the valve spindle (18) to secure it against distortion. -

Page 143: Connect The Electrics

4 Assembly Damage to the equipment due to damaged wiring! When removing the cover it is possible to tear or damage the wiring in the cover. • Remove the cover carefully. ATTENTION Remove the cover (201) carefully. Disconnect the plug connection between motherboard (110) and cover (201). ... - Page 144 4 Assembly Check the power supply voltage. If the required tolerance of the power supply voltage cannot be maintained with a mains transformer, an AC voltage regulator must be used. 2.5 Technical data on page 10. Proceed as follows to switch the electrics on: Remove the (201) cover.

-

Page 145: Control-Independent Switching

4 Assembly Terminal Description UB, N1 Supply voltage Control voltage for downward movement in Three-point mode Control voltage for upward movement in Three-point mode Feedback signal in "Manual mode" • R= 24 V DC max. 35 mA B1, B2 Binary input / Frost protection function Zero potential for signals X, Y and R •... -

Page 146: Remove Printed Circuit Board Cover

4 Assembly 4.5.2 Remove printed circuit board cover The printed circuit board cover must be removed (33) first in order to adjust the linear actuator via the coding switches. Electric shock due to live components! If the power supply is switched off, there is danger of electric shock due to live components. -

Page 147: Way-Switch Printed Circuit Board Installation

4 Assembly 4.6.1 Way-switch printed circuit board installation Electric shock due to live components! If the power supply is switched off, there is danger of electric shock due to live components. WARNING • Prior to starting work ensure that the actuator is disconnected safely from the mains power supply. -

Page 148: Fit The Printed Circuit Board For Ma Output Signal

4 Assembly 123 Pin strip Diagram 12 Pin strip for way-switch printed circuit board on the motherboard Adjust the way-switch. 5.8 Set potential-free way-switch on page 25 4.6.2 Fit the printed circuit board for mA output signal. Electric shock due to live components! If the power supply is switched off, there is danger of electric shock due to live components. - Page 149 4 Assembly JP1 113 JP1 Jumper 110 Main board 27 Spacers 111 Printed circuit board for mA output signal 113 Plug-in bridge Diagram 13 Installation of the printed circuit board for mA output signal Select the output signal range with the jumper (JP1): •...

-

Page 150: Commissioning

5 Commissioning 5 Commissioning Electric shock due to live components! If the power supply is switched off, there is danger of electric shock due to live components. WARNING • Prior to starting work ensure that the actuator is disconnected safely from the mains power supply. -

Page 151: Set Input Signal

5 Commissioning Switch Ready for operation X characteristic X characteristic Stroke Stroke curve curve Y characteristic Y characteristic Stroke Stroke curve curve Input signal (Y) Input signal (Y) 0 … 10 V DC or 0 … 20 mA 2 … 10 V DC or 4 … 20 mA Actuating time 3.5 s/mm Actuating time 5 s/mm Autotest and Autopause on... -

Page 152: Set Hysteresis

5 Commissioning Set hysteresis 0,15 V 0,05 V 0,3 V 0,5 V Diagram 18 Set hysteresis For further information 2.4.6 Hysteresis on page 9 Set actuating direction The actuating direction of the linear actuator can be reversed at the coding switch (inverted operation). -

Page 153: Set Limit Position

5 Commissioning Set limit position Select the limit position for the linear actuator using coding switch S7: • S7 ON: Limit position with extended spindle nut • S7 OFF: Limit position with retracted spindle nut The limit position is approached in the following situations: •... - Page 154 5 Commissioning Open the cover (201). 4.4 Fit/remove cover on page 14 The way-switch printed circuit board is located in the cover (106). Use a screwdriver to turn the trimmer potentiometer until the way-switch switches. The associated LED goes on or off during this operation. Use potentiometer P1 (105 P1) to set way-switch 1.

-

Page 155: Initialise The Path-Measuring System

5 Commissioning Initialise the path-measuring system Linear actuator starts up automatically! Immediately upon connecting the power supply, the linear actuator moves automatically to a path-measuring system reference point. ATTENTION • Wait until the reference point has been reached and the linear actuator stops. The incremental path-measuring system must be initialised upon completion of the following tasks: •... - Page 156 5 Commissioning 5.10 Commissioning Check that all installation and assembly tasks have been completed correctly. 4 Assembly on page 12 Ensure that the electric actuation of the linear actuator is ensured without danger to persons or equipment or the system. Ensure that the linear actuator is correctly fixed and the linear actuator cover is closed.

-

Page 157: Commissioning

6 Operation 6 Operation Before the linear actuator can be operated, it must be initialised and the operating mode selected. 5 Commissioning on page 22 5.9 Initialise the path-measuring system on page 27 Switching between Manual and Automatic modes The linear actuator can be operated in Automatic mode or in Manual mode (manual adjustment). -

Page 158: Led Display

7 Maintenance, Care and Repairs LED display The LEDs in the viewing window (47) indicate operating states or faults. 10.2 Operating faults checklist on page 32 Green LED Operating status / fault Normal operation, standby The LED illuminates continuously, actuator awaits drive duration command. -

Page 159: Shutdown And Disposal

9 Shutdown and Disposal Equipment damage due to defective spare parts! Spare parts must comply with the technical requirements specified by the manufacturer. ATTENTION • Use only original spare parts. 2.1 Components on page 6 2.2 Accessories on page 7 9 Shutdown and Disposal Dispose of the linear actuator in accordance with national regulations and legislation. -

Page 160: Operating Faults Checklist

10 Troubleshooting 10.2 Operating faults checklist Fault Cause/reason Remedy 1. Linear actuator does not Handwheel (36) is in manual mode position Switch handwheel to automatic mode work. position. Mains power failure Establish cause and eliminate. Fuse defective. (in the electrical cabinet) ...

Need help?

Do you have a question about the MC55/230 and is the answer not in the manual?

Questions and answers