Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summarization of Contents

1 Preface

1.1 Manufacturer’s Details

Details about the manufacturer, including contact information and website.

1.2 About This Manual

Explains the purpose and content of the manual.

1.3 About This Product

General information about the product itself, including identification and scope of supply.

2 For Your Safety

2.1 Usage Guidelines

Defines proper and improper use of the machine, including safety consequences.

2.3 Warning Information

Explains hazard classes, warning structures, and danger symbols on the machine.

2.4 Product Safety Guidelines

Covers fundamental safety, transport, operation, maintenance, cleaning, and particular dangers.

2.5 Emergency Procedures

Instructions for handling faults and emergencies, including behavior and restarting.

2.6 Responsibilities

Outlines duties of the operating company and personnel, including selection and qualification.

2.7 Regulatory Compliance

Lists applicable safety regulations, primarily for the Federal Republic of Germany.

3 Product Description

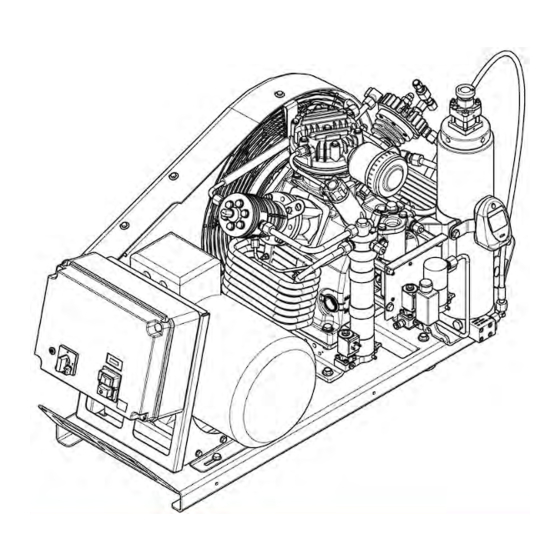

3.1 Structure and Function

Describes the physical structure, function schematic, and operational principles of the unit.

3.2 Display Elements

Details the various display and indicator elements, including B-TIMER and B-SECURUS.

3.3 Control Elements

Identifies and explains control elements like main switch and filling equipment.

3.4 Operating Modes

Explains the manual and semi-automatic modes of operation.

4 Technical Data

4.1 Compressor Unit Technical Data

Provides technical specifications for various compressor unit models (PE 200-TB, TE, etc.).

4.2 Compressor Block Technical Data

Details technical specifications for the IK120 compressor block.

4.3 Filter System Technical Data

Provides technical specifications for filter systems P21, P31, and P41.

4.4 Motor Technical Data

Information on obtaining motor technical data from the rating plate.

5 Transport and Storage

5.1 Transport Procedures

Guidelines and safety precautions for checking, preparing, and transporting the unit.

5.2 Storage and Preservation

Procedures for selecting a storage location, preparing for preservation, and inspecting during storage.

6 Installation

6.1 Installation Site Preparation

Requirements for preparing the location where the unit will be installed.

6.2 Unit Installation

Procedures and safety precautions for installing the unit.

6.3 Electrical Connection

Instructions and safety warnings for connecting the unit electrically.

6.4 Unit Acceptance

Requirements for site inspection and acceptance before commissioning.

7 Commissioning and Operation

7.1 Starting Up the Unit

Steps and checks required before starting the unit, including first-time and post-downtime commissioning.

7.2 Operation

Guidelines and safety for operating the unit, including switching on/off, monitoring, and emergency behavior.

7.2.5 Operating the B-TIMER

Guide to operating the B-TIMER display, toggling information, and resetting maintenance counters.

7.2.6 Filling Operation

Procedures for safely filling compressed air cylinders, including flushing the unit.

8 Troubleshooting

8.1 Fault Finding

General guide to identifying and correcting faults in drive motor, compressor block, and electrical systems.

8.1.3 Condensate Drain Faults

Troubleshooting guide for issues with the automatic condensate drain.

8.1.5 B-TIMER Error Displays

Explanation of B-TIMER error messages and required actions.

9 Maintenance

9.2 Maintenance Table

Overview of scheduled maintenance activities and their intervals.

9.3 Maintenance Resources

Information on bolt torques, sequences, lubricants, adhesives, test mediums, and filter cartridges.

9.4 Lubricating Oil System

Procedures for checking oil level, changing oil, changing oil type, and venting the oil pump.

9.5 Intake Section Maintenance

Instructions for replacing the suction filter element.

9.6 Filter System Maintenance

General advice, load cycles, service life determination, and cartridge replacement for filter systems.

9.7 Pressure Retention Valve

Procedures for checking and adjusting the pressure retention valve.

9.8 Filling Equipment Maintenance

Guidelines for checking filling hoses and maintaining filling valves.

9.9 Safety Valves Maintenance

Safety precautions and procedures for checking the blow-off pressure of safety valves.

9.10 Pressure Gauge Maintenance

Procedures for checking and maintaining pressure gauges.

9.11 Valve Maintenance

Procedures for servicing and replacing intake and pressure valves.

9.12 Automatic Condensate Drain

Checking function and adjusting the timer for the automatic condensate drain.

9.13 Electrical System Maintenance

Procedures for maintaining electrical control systems, pressure switch, and B-TIMER battery.

9.14 Drive System Maintenance

Covers electric motor maintenance and V-belt maintenance.

10 Disassembly and Disposal

10.1 Decommissioning

Steps to safely shut down and prepare the unit for decommissioning.

10.2 Dispose the Unit

Instructions for environmentally sound disposal of the unit and its components.

11 Appendix

11.1 Declaration of Conformity

Example of the conformity declaration provided with the machine.

11.2 Electrical Connection Data (230V)

Table of electrical connection values for three-phase motors (230 V).

11.3 Electrical Connection Data (400V/500V)

Table of electrical connection values for three-phase AC motors (400 V / 500 V).

11.4 Filter Cartridge Replacement Intervals

Information on determining filter cartridge replacement intervals based on operating hours and cylinder fillings.

11.5 Maintenance Booklet

Information about the maintenance booklet and operator instruction form.

11.5.2 Maintenance Schedule

Detailed table of maintenance tasks and their intervals based on operating hours and months.

Need help?

Do you have a question about the POSEIDON PE 300-TE and is the answer not in the manual?

Questions and answers