Summarization of Contents

I INTRODUCTION

1.1 IDENTIFICATION OF THE UNIT

Details unit identification plates showing model, serial number, airflow, and motor specifications.

1.2 CHECK OPERATIONS

Lists inspection checks performed during production, including dimensions, gaskets, and plates.

1.3 PACKING AND TRANSPORT

Guidelines for packing and transporting units, including handling critical components and securing to trucks.

1.4 INSPECTION OF THE GOODS RECEIVED

Procedures for checking unit integrity, paneling, and components upon delivery to identify transport damages.

1.5 MOVEMENT AND INSTALLATION

Safe methods for moving and installing units using lifters, forklifts, or cranes, noting lifting points.

1.6 POSITIONING AND JUNCTION OF SECTIONS

Instructions for aligning and joining modular unit sections on a level surface for proper function.

1.7 UNIT CLEANING

Recommendations for cleaning the unit's interior, floor, and drain pan before initial startup.

3 CONNECTIONS

3.1 DUCTS LINKAGE

Guidelines for connecting supply and return ducts using flanges and flexible joints to minimize vibration.

3.2 COILS CONNECTION

Procedures for connecting water, steam, and freon coils, emphasizing hydraulic plant requirements and counterflow.

3.3 CONDENSATE DRAIN PANS

Information on drain pipe installation, siphoning requirements, and cleaning of condensate drain pans.

3.3.1 SIPHONING

Details on siphon dimensioning for drain pans based on fan pressure (inlet vs. supply) for proper drainage.

3.4 CONNECTION OF HUMIDIFICATION SECTIONS

Instructions for connecting humidification systems, including feed pipes, water softeners, and drain siphoning.

3.4.1 HONEYCOMB HUMIDIFICATION SYSTEM

Steps for setting up honeycomb humidifiers, focusing on water flow adjustment and system types.

3.4.2 HUMIDIFICATION WITH NOZZLES BENCH

Guidance on connecting humidifiers with nozzles, ensuring correct water pressure and nozzle sprinkling.

3.5 CONNECTION OF STEAM HUMIDIFICATION

Procedures for connecting steam feeding pipes and condensate drain pipes for steam humidification systems.

3.6 CONNECTION OF PLATE HEAT RECOVERY UNITS

Focuses on condensate drain pan siphoning and filter cleanliness for plate heat recovery units.

3.7 CONNECTION OF THE FAN SECTION

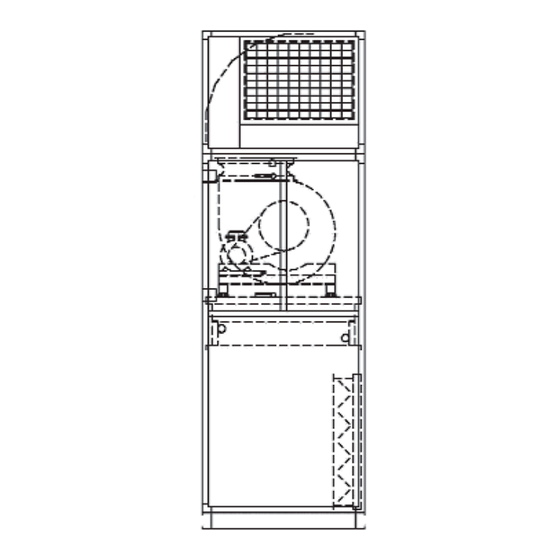

Checks for fan-motor set mounting, safety device installation, and motor direction before commissioning.

3.7.1 SAFETY EQUIPMENTS

Electrical connection of safety switches and precautions for safely opening fan section access doors.

3.7.2 PREPARATORY OPERATIONS FOR COMMISSIONING

Steps before starting the unit, including motor connections, grounding, and checking fan rotation.

3.7.3 BELTS TENSION

Procedures for checking and adjusting trapezoidal belt tension for optimal transmission performance and wear.

3.7.4 BEARINGS LUBRICATION

Guidance on lubricating bearings every six months for units equipped with grease cups.

3.7.5 ANTIVIBRATION BENCH

Action to remove locking plates from the antivibration bench before commissioning to allow proper spring function.

3.8 ELECTRICAL CONNECTIONS

Covers electrical connections for motors, heaters, and pumps, including wiring and protection.

3.8.1 MOTORS

Details on motor specifications, compliance with regulations, winding types, and connection methods (star/delta).

3.8.2 ELECTRIC HEATERS

Instructions for connecting electric heaters, adjusting thermostats, and limiting operating temperatures to prevent overheating.

3.8.3 ELECTRIC PUMPS

Guidelines for connecting electric pumps, following manufacturer instructions, and avoiding dry running.

4 FILTRATION

4.1 SYNTHETIC OR METALLIC FILTERS

Information on regenerable synthetic or metallic filters, their mounting, and cleaning when pressure drop exceeds 120 Pa.

4.2 BAG FILTERS

Details on non-regenerable bag filters, their mounting, and replacement when clogged.

4.3 ABSOLUTE FILTERS

Information on absolute filters, their replacement when clogged, and initial run without them for circuit cleaning.

4.4 AUTOROLL FILTERS

Description of autoregenerating filters equipped with a control board for automatic renewal of filtering medium.

4.5 ACTIVATED CARBON FILTERS

Details on activated carbon filters, chemical regeneration, replacement of soaked cartridges, and disposal of exhausted carbon.

6 OPERATIONAL MAINTENANCE LAYOUT

6.1 MONTHLY CHECKS

Specific checks to perform monthly, including fan rotor cleaning and belt tension/wear inspection.

6.2 YEARLY CHECKS

Annual maintenance tasks covering electrical connections, belt alignment, motor condition, and fan scroll cleanliness.

Need help?

Do you have a question about the CTA 48 and is the answer not in the manual?

Questions and answers