Summarization of Contents

I INTRODUCTION

1.1 IDENTIFICATION OF THE UNIT

Identifies unit model, serial number, and key specifications via an identity plate.

I INTRODUCTION

1.2 CHECK OPERATIONS

Details pre-shipment inspection checks performed on NOVAIR products.

1.3 PACKING AND TRANSPORT

Covers unit mounting, sectional manufacturing, and safe handling during transport.

I INTRODUCTION

1.4 INSPECTION OF THE GOODS RECEIVED

Outlines checks for structural integrity and component presence upon delivery.

1.5 MOVEMENT AND INSTALLATION

Provides guidance on safe lifting and handling procedures for units using lifters or cranes.

I INTRODUCTION

1.6 POSITIONING AND JUNCTION OF SECTIONS

Details requirements for placing and joining modular sections on a levelled floor for optimal performance.

I INTRODUCTION

1.7 UNIT CLEANING

Recommends cleaning procedures before initial unit startup to ensure proper function.

2 SAFETY PRESCRIPTIONS

General Safety Measures

Emphasizes qualified personnel, technical knowledge, and risk avoidance for unit operation.

3 CONNECTIONS

3.1 DUCTS LINKAGE

Advises on connecting supply and return ducts using suitable flanges and flexible joints to minimize vibration.

3 CONNECTIONS

3.2 COILS CONNECTION

Guides on hydraulic connections for coils, including vent, drainage, and counterflow for thermal efficiency.

3 CONNECTIONS

3.3 CONDENSATE DRAIN PANS

Explains the importance of siphoning drain pipes and checking pan cleanliness.

3 CONNECTIONS

3.4 CONNECTION OF HUMIDIFICATION SECTIONS

Details connecting humidification sections, feeding water, and system operation.

3 CONNECTIONS

3.5 CONNECTION OF STEAM HUMIDIFICATION

Covers steam feeding and condensate drain pipe connections for steam humidification systems.

3.6 CONNECTION OF PLATE HEAT RECOVERY UNITS

Details condensate drain pan siphoning and exchanger cleanliness for heat recovery units.

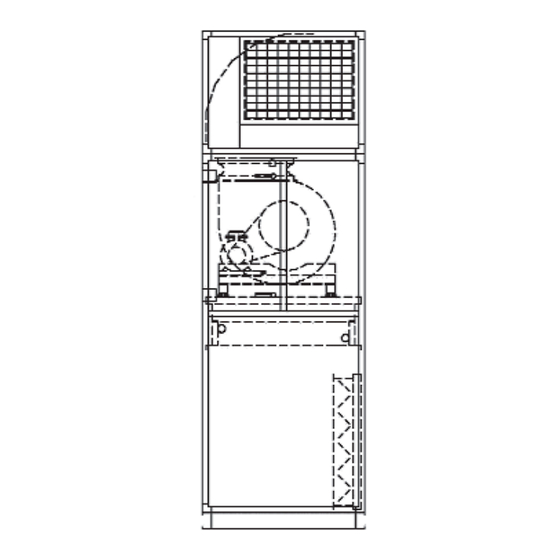

3.7 CONNECTION OF THE FAN SECTION

Guides on checking motor-fan set mounting and safety device installation during commissioning.

3.8 ELECTRICAL CONNECTIONS

3.8.1 MOTORS

Details specifications of electric motors used, including voltage, winding, and insulation class.

3.8.2 ELECTRIC HEATERS

Provides instructions for connecting electric heaters and setting temperature limits to prevent overheating.

3.8 ELECTRICAL CONNECTIONS

3.8.3 ELECTRIC PUMPS

Guides on connecting electric pumps and avoiding dry running to prevent premature wear.

4 FILTRATION

4.1 SYNTHETIC OR METALLIC FILTERS

Describes regenerable filters, clogging checks, and cleaning methods for synthetic or metallic filters.

4 FILTRATION

4.2 BAG FILTERS

Explains that bag filters are non-regenerable and require replacement when clogged.

4.3 ABSOLUTE FILTERS

Covers non-regenerable absolute filters, their replacement, and initial run without them for circuit cleaning.

4.4 AUTOROLL FILTERS

Discusses autoroll filters with continuous regeneration and automatic renewal based on pressure gauge control.

4 FILTRATION

4.5 ACTIVATED CARBON FILTERS

Describes regenerable activated carbon filters and their replacement process.

6 OPERATIONAL MAINTENANCE LAYOUT

6.1 MONTHLY CHECKS

Details specific checks for fan rotor cleanliness and belt tension/wear to be performed monthly.

6.2 YEARLY CHECKS

Outlines comprehensive checks for electrical connections, belts, alignment, and motor condition annually.

Need help?

Do you have a question about the CTA Series and is the answer not in the manual?

Questions and answers