Summarization of Contents

Introduction

Purpose of this Manual

Manual provides guidance for installation, operation, and maintenance of specific control valves.

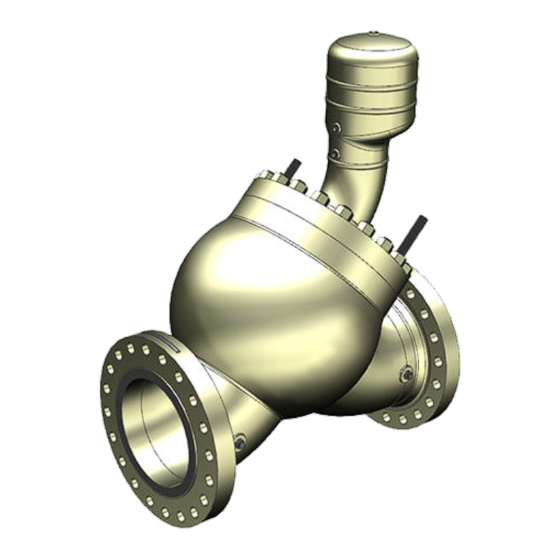

Model Descriptions

Details features, applications, operation, and components of the control valves.

Parts List

Lists all components and part numbers for specific control valve models.

Agency Certifications

Lists product agency certifications applicable to the Daniel control valves.

Operating Conditions and Specifications

Operating Conditions for Control Valves

Details environmental and process conditions for control valve operation.

Design Considerations

Outlines factors to consider when designing the system for the control valve.

Environmental Conditions

Describes conditions like corrosive service, populated areas, and ventilation for valve installation.

Control Valve Description and Interface

Interface Requirements

Specifies requirements for connecting the control valve, focusing on flange types.

Installation Requirements and Limitations

Outlines necessary regulations, company requirements, and flushing procedures for installation.

Minimum Clearances

Refers to certified prints for minimum clearance requirements for installation, operation, and maintenance.

Prepare Control Valve for Use

Lifting Conditions and Safety

Safety precautions and conditions for lifting and moving the control valve.

Configure and Orient Valve

Instructions for configuring the control valve, including orientation and piping.

Installation Procedures

Installation Prerequisites and Torque

Covers pre-start checks, torque information, values, patterns, tools, and nitrogen systems.

External Component Assembly

Instructions for assembling external components like flanges onto the pipeline.

Oil Filling Procedure

Step-by-step guide for filling the oil reservoir using sight gauges.

Commissioning the Control Valve

Procedures for commissioning the control valve after installation to ensure proper operation.

Operation Parameters

Normal Operation and Features

Describes normal operation, features, and benefits of the control valves.

Oil Reservoir and Specifications

Explains the function of oil reservoir sight gauges and oil specifications.

Applications

Details common applications like back pressure control and pipeline pump station bypass.

Maintenance Procedures

Planned Maintenance Tasks

Outlines recommended tasks for inspection, cleaning, corrosion monitoring, and lubrication.

Corrective Maintenance and Troubleshooting

Provides troubleshooting for valve issues and verification of operational condition.

Recommended Spare Parts

Lists recommended spare parts, including O-ring kits, for various valve models and sizes.

Decommissioning

Shut Down and Shipment

Steps to shut down, disassemble, and prepare the control valve for storage or shipment.

Need help?

Do you have a question about the 767 and is the answer not in the manual?

Questions and answers