Summarization of Contents

Signal Words and Safety Symbols

Understanding Safety Alerts

Explains signal words and safety symbols used in the manual for hazard communication.

Important Safety Instructions

General Safety Guidelines

Emphasizes reading and following all instructions and warnings for safe operation.

Warranty and Limitations

Limited Warranty Terms

Details Daniel's warranty for products and services, including exclusions.

Limitation of Remedy and Liability

Defines buyer's remedies and Daniel's liability limits for damages.

Introduction to Control Valves

Purpose of this Manual

Provides guidance on installation, operation, and maintenance of Daniel control valves.

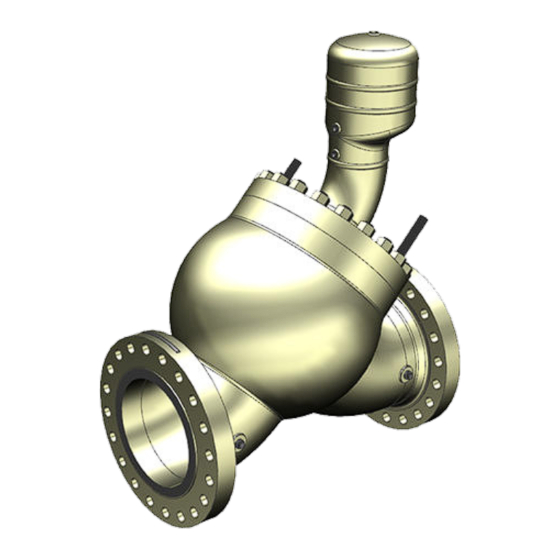

Description of Models 762, 763, 765, 766, 767

Details the features and applications of the specified Daniel control valve models.

General Control Valve Features

Details features and benefits of the Daniel control valve series.

Control Valve Operation Overview

Explains the operational mechanism of the control valve, including opening and closing speeds.

Control Valve Parts List

Parts for 2-inch Valves

Lists components and part numbers for the 2-inch model control valves.

Agency Certifications

Applicable Control Valve Certifications

Lists the product agency certifications applicable to Daniel Control Valves.

Operating Conditions and Specifications

Control Valve Operating Conditions

Specifies temperature, pressure, fluid velocity, and fluid types for control valve operation.

Design Considerations for Control Valves

Outlines key factors to consider during the design and selection of control valves.

Environmental Conditions for Operation

Details how environmental factors affect valve performance.

Control Valve Description and Interfaces

Interface Requirements

Details mechanical connection requirements, specifically flange types for the control valves.

Installation Requirements and Limitations

Outlines compliance with regulations, line flushing, and flange size considerations for installation.

Control Valve Dimensions

45° In-line Installation Dimensions

Provides dimensional data for 45° in-line installation.

45° Horizontal Installation Dimensions

Provides dimensional data for 45° horizontal installation.

Shipping Weight and Volume

Vertical Installation Shipping Data

Lists approximate shipping weights and volumes for vertical installation.

Control Valve Handling

Receiving and Inspecting the Valve

Provides instructions for receiving, unpacking, and inspecting the control valve.

Storing the Control Valve

Details procedures for storing the control valve, including rust inhibition, packing, and conditions.

Preparing the Control Valve for Use

Lifting and Installation Conditions

Specifies conditions for safe lifting and installation.

Personnel Lifting Requirements and Safety

Outlines requirements for trained personnel and safety precautions when using lifting slings.

Configuring the Control Valve and Orientation

Covers configuring internal components and determining correct valve orientation.

Piping Recommendations for Installation

Provides recommendations for piping connections and bolt requirements.

Installation Prerequisites

Pre-Start Checks and Torque Procedures

Details pre-installation checks, torque information, and procedures for tightening flanges.

Torque Values and Patterns

Provides reference torque values and tightening sequences for flanges.

Tools for Control Valve Installation

Lists required tools for flange installation and component handling.

Typical Installation Overview

Illustrates a typical installation of a gas loaded pressure relief valve.

Nitrogen System Requirements

Describes the nitrogen system's role in maintaining constant pressure.

Gas Plenum Tank Installation and Sizing

Details procedures for installing and sizing gas plenum tanks.

Nitrogen System Panel Functionality

Explains the advantages of nitrogen control panels.

Installation Procedure

External Components Assembly and Fasteners

Details assembly of external components and fastener selection.

Oil Filling Procedure for Valves

Provides a guide for filling the oil reservoir and checking oil levels.

Testing the Product

Commissioning the Control Valve

Outlines steps to commission the control valve after installation.

Operation Parameters

Control Valve Normal Operation

Describes the standard operating principle of Daniel's control valves.

Features and Benefits of Control Valves

Highlights key design features and benefits.

Oil Reservoir Functionality and Indicators

Explains the function of the oil reservoir and sight gauges.

Control Valve Applications

Details typical applications such as back pressure control and pump station by-pass.

Planned Maintenance

Maintenance Considerations and Tools

Outlines considerations for performing maintenance and lists necessary tools.

Disassembly and Assembly Procedures

Details procedures for disassembling and assembling the control valve.

NPS 16 Valve Cylinder Disassembly

Provides specific disassembly procedures for the NPS 16 valve cylinder.

Mechanical Assembly and Torque Specifications

Details mechanical assembly steps and torque specifications.

Cylinder Reassembly (NPS 2-12)

Provides steps for reassembling the cylinder and cylinder head for 2-12 inch valves.

Cylinder Reassembly (NPS 16 Valve)

Details steps for reassembling the cylinder assembly for NPS 16 valves.

Planned Maintenance Tasks and Schedules

Outlines planned maintenance tasks including inspection, cleaning, and lubrication.

Corrective Maintenance

Control Valve Troubleshooting Guide

Provides a troubleshooting table for common control valve issues.

Spare Parts

Recommended Spare Parts List

Lists recommended spare parts, including valve assembly O-ring kits, by NPS size and Daniel Class.

Decommissioning the Control Valve

Shutting Down the Control Valve

Provides steps for safely shutting down and disassembling the control valve.

Shipment of the Control Valve

Directs users to the preface for shipment information.

Need help?

Do you have a question about the 766 and is the answer not in the manual?

Questions and answers