Summarization of Contents

Health & Safety

Static Electricity

Ensuring proper earthing for compressors and ancillaries to prevent static discharge and potential explosion hazards.

Drive Line Safety

Responsibility for guarding rotating and moving parts to comply with safety legislation.

Compressor Hazards

Warning against placing objects or fingers into compressor apertures due to internal moving parts.

Installation Safety

Proper installation of relief valves to prevent venting hot air onto personnel.

Storage and Low Use Precautions

Guidelines for storing the compressor and periodic operation during low use periods.

Fire Hazard

Warning about fluoroelastomer polymer seals degrading above 300°C and handling precautions.

Relief Valve Check Procedure

Monthly procedure to clear the valve seat and check the relief valve functionality.

Noise Levels

Information on typical maximum noise levels for the XK12 compressor.

General

Product General Description

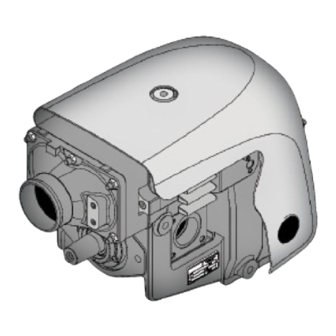

Overview of the XK12 screw compressor, its design, and intended use for dense bulk powder discharge.

Drive Options

Details the different drive systems available for the XK12 compressor, including PTO and engine drives.

Available Packages

Description of standard compressor packages, Package 1 (absorptive) and Package 2 (reactive).

Specifications and Environment

Details dimensions, performance data, and the permissible operating environment for the XK12.

Installation

General Installation Considerations

Points to consider when selecting the machine mounting position for optimal operation and access.

Lifting Procedures

Instructions and safety precautions for lifting the basic compressor unit.

Mounting the Compressor

Guidance on vertically mounting the XK12 using its feet and drive rotation options.

Lubrication

Instructions for checking and topping up the gearcase oil level.

PTO and Propeller Shaft Drive Alignment (DIN)

Detailed steps for aligning DIN type PTO and propeller shafts, including coupling and torque specifications.

PTO and Propeller Shaft Drive Alignment (SAE)

Detailed steps for aligning SAE type PTO and propeller shafts, including coupling and torque specifications.

Pipe Work and Commissioning Filter

Guidelines for pipe work installation and the use of the commissioning filter.

Ancillary Components

Description and installation guidance for ancillaries: relief valve, silencer, check valve, torque coupling, ball valve.

Package 1 Details

Breakdown and parts list for Package 1 with absorptive discharge silencer.

Package 2 Details

Breakdown and parts list for Package 2 with reactive discharge silencer.

Commissioning

Pre-Commissioning Checklist

A checklist of items to verify before starting the commissioning process.

Commissioning Filter and Probes

Instructions for the inlet commissioning filter and monitoring probe installation.

Commissioning Procedure

Detailed steps for commissioning the XK12 compressor, including pressure, temperature, and leak checks.

Driver Operating Instructions

Essential operating instructions for drivers, covering starting, stopping, and safe handling.

Driver Training Content

Key topics for driver training: safety, operation, and routine maintenance.

Maintenance

Maintenance Schedule

Recommended daily, weekly, monthly, and annual maintenance tasks for the XK12 compressor.

Gearcase Oil Change

Step-by-step instructions for draining and refilling the gearcase oil.

Valve Maintenance

Procedures for checking and maintaining check valves and relief valves.

Silencer and Pipework Maintenance

Guidance on inspecting silencers and pipework for damage, corrosion, and repainting.

Air Inlet Filter Maintenance

Instructions for cleaning and replacing the cyclonic air inlet filter element.

Alternative Oils

Information on acceptable alternative oils and compatibility considerations.

Need help?

Do you have a question about the DRUM XK12 and is the answer not in the manual?

Questions and answers