Summary of Contents for Gardner Denver GD 70

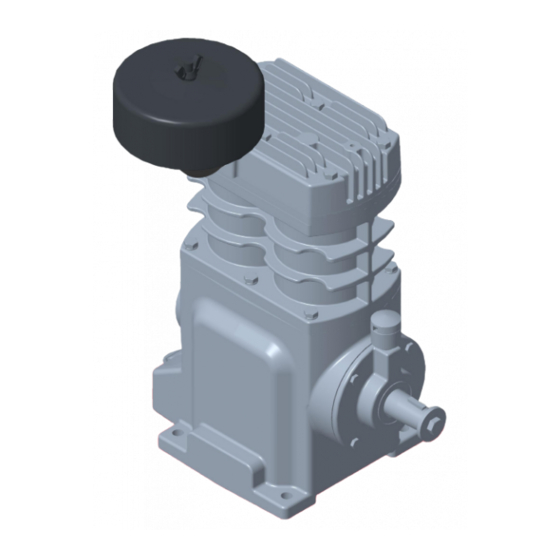

- Page 1 Parts List, Operating & Service Manual GD 70 COMPRESSOR HYD-7-610 Version 00 February 26, 2021 Models GD 70...

-

Page 2: Table Of Contents

� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4 GARDNER DENVER SYNTHETIC LUBRICANT � � � � � � � � � 16 GENERAL INFORMATION �... - Page 3 MAINTAIN RELIABILITY AND PERFORMANCE WITH GENUINE GARDNER DENVER PARTS AND SUPPORT SERVICES Factory genuine parts, manufactured to design tolerances, are developed for optimum dependability ------ specifically for your compressor. Design and material innovations are born from years of experience with hundreds of different applications. When you specify factory genuine parts, you are assured of receiving parts that incorporate the most current design advancements manufactured in our state-of the- art factory under exacting quality standards.

-

Page 4: Safety

DANGER Intake air can contain carbon monoxide or other contaminants. Will cause serious injury or death. Gardner Denver air compressors are not designed, intended or approved for breathing air. Compressed air should not be used for breathing air applications unless treated in accordance with all applicable codes and regulations. -

Page 5: Receipt & Inspection

RECEIPT & INSPECTION Ensure adequate lifting equipment is available for unloading and moving If you discover damage after receiving the unit (concealed damage), the the compressor to the installation site. carrier must be notified within 15 days of receipt and an inspection must be requested by telephone with confirmation in writing. -

Page 6: Installation

ASME approved safety/relief valve between the compressor discharge and the restriction. CAUTION If you will be using Gardner Denver synthetic compressor lubricant, all downstream piping material and system components must be compatible. Refer to the following material compatibility list. If there are incompatible materials present in your system, or if there are materials not included in the list, contact Gardner Denver for recommendations. -

Page 7: General Requirements

• DIRECT DRIVE 40-80 4.4-26.7 A 1100 series flange is available to direct drive the GD 70. The following 80-125 26.7-51.0 guidelines should be followed: • Compressor shaft and PTO shaft should be parallel within 2 degrees. • Maximum compound drive angle must be no greater than 11 degrees. -

Page 8: Filling Procedures

Slowly fill the crankcase with lubricant until thelubricant reaches the top thread of the oil fill opening and the top of the sight glass. Crankcase capacity for the GD 70 is one (1) liter. Replace the oil fill plug HAND TIGHT ONLY. -

Page 9: Operation

„ GENERAL Your air compressor was designed for 100% continuous duty operation with the use of Gardner Denver svnthetic compressor lubricant and 60% continuous duty operation with the use of petroleum lubricant. In other words synthetic lubricant allows the compressor to pump continuously without cycling. -

Page 10: Maintenance

MAINTENANCE „ FILTER REMOVAL/REPLACEMENT WARNING 1. Unscrew and remove the wing nut (A) securing the filter housing (B) to its base (C). Release air pressure from the system before performing maintenance. 2. Remove the filter housing and withdraw the old filter element. Clean or replace the element. -

Page 11: Troubleshooting

TROUBLESHOOTING PROBLEM POSSIBLE CAUSE POSSIBLE SOLUTION Lubricant viscosity too low Drain existing lubricant and refill with proper lubricant. Lubricant level too low Add lubricant to crankcase to proper level. Detergent type lubricant being used Drain existing lubricant and refill with proper lubricant Abnormal piston, ring or cylinder wear. - Page 12 PROBLEM POSSIBLE CAUSE POSSIBLE SOLUTION Clogged or dirty inlet and/or discharge line Clean or replace filter. Lubricant viscosity too low Drain existing lubricant and refill with proper lubricant Detergent type lubricant being used Drain existing lubricant and refill with proper lubricant Piston rings damaged or worn (broken, rough Install ring kit...

-

Page 13: Parts List (Gd70)

PARTS LIST (GD70) HYD-7-610 EN-13... - Page 14 REF. NO. PART NO. DESCRIPTION QTY. CANT. QTÉ. REF. 700000300 PUMP, BARE COMPRESSOR 20102703 SET, PISTON RING RING, COMPRESSION RING, SCRAPER RING, OIL CONTROL SPACER RING, OIL CONTROL 95033593 PLUG, OIL DRAIN 96706874 CAPSCREW. M8X65 (HEAD BOLT) 96702253 CAPSCREW. M8 X25 (CYLINDER BOLT) 96728316 WASHER.

- Page 15 54429600 GASKET, VALVE PLATE 97333546 GASKET, CYLINDER 54571617 GASKET, HEAD 97334270 GLASS, SIGHT 54410683 HEAD 70243936 ASSEMBLY, VENT P04999A FILTER, INLET (SEE PAGE 17 FOR REPLACEMENT ELEMENT) 64U1 ELBOW,PIPE NOT SOLD SEPARATELY AVAILABLE lNDlVlDUALLY OR IN VALVE KIT 300HUA6017 AVAILABLE INDIVIDUALLY OR IN PISTON RING KIT 300HUA6012 AVAILABLE INDIVIDUALLY OR IN INSTALL KIT 300HUA6003 HYD-7-610 EN-15...

- Page 16 Kit, Install , Elbow Valve wearing park and 301HUA6003 Kit, Install, Straight head gaskets that are 300HUA6017 Kit, Valve/Gasket destroyed in replacing „ GARDNER DENVER SYNTHETIC LUBRICANT valve park. Part No. Description Complete set of piston rings, a crankshaft seal, and P13930A Lubricant.

- Page 20 Gardner Denver, Inc 1800 Gardner Expressway Quincy, IL 62305 Customer Service Department Telephone: (800) 682-9868 pd.bloweers@gardnerdenver.com www.gardnerdenverproducts.com ©2021 Gardner Denver, Inc. Printed in U.S.A...

Need help?

Do you have a question about the GD 70 and is the answer not in the manual?

Questions and answers