Table of Contents

Advertisement

Quick Links

Operator's Manual

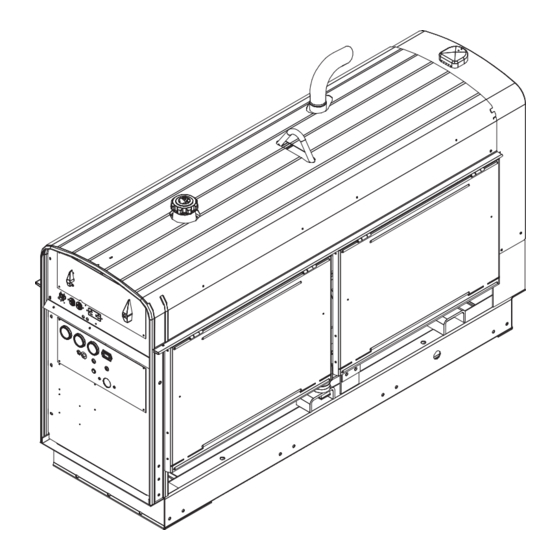

SAE-500

POWER SOURCE

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IM988-A

| Issue D ate Nov-15

© Lincoln Global, Inc. All Rights Reserved.

TM

DC ARC WELDING

For use with machines having Code Numbers:

11476, 12515

Advertisement

Table of Contents

Summarization of Contents

Essential Safety Practices

Equipment Inspection & Handling

Inspect equipment upon receipt for damage and follow general safe operation guidelines.

Respiratory Safety

Keep head out of fumes and ensure adequate ventilation during welding.

Personal Protective Gear

Wear appropriate eye, ear, and body protection for welding.

Specific Hazard Warnings & Guidelines

California Proposition 65 Compliance

Understand and adhere to California's warnings for diesel exhaust and welding fumes.

Engine Safety Protocols

Follow critical safety instructions for engine operation and maintenance.

Electric & Magnetic Field (EMF) Awareness

Learn about EMF hazards and implement procedures to minimize exposure.

Detailed Electrical & Arc Safety

Electric Shock Prevention

Strict measures to avoid electrical shock from live parts and improper grounding.

Arc Ray Protection

Use proper shielding and clothing to protect from arc rays and spatter.

Welding Fume & Gas Hazards

Detailed information on fume toxicity, ventilation, and gas displacement hazards.

Fire, Explosion, and Cylinder Safety

Fire & Explosion Prevention

Measures to prevent fires and explosions caused by welding sparks and hot materials.

Compressed Gas Cylinder Safety

Guidelines for safe handling, storage, and use of compressed gas cylinders.

Electrical Equipment Safety

Proper installation and grounding of electrically powered equipment.

Technical Specifications

Diesel Engine Details

Specifications for the Kubota diesel engine, including HP, displacement, and RPM.

Welder Output Ratings

Details on duty cycle, welding output, and voltage at rated amps.

Welder/Generator Output

Welding range, open circuit voltage, and auxiliary power specifications.

Physical Dimensions and Weight

Provides height, width, depth, and weight of the machine.

Installation Guidelines

Location and Ventilation Requirements

Proper placement for airflow and exhaust venting to ensure optimal operation.

Machine Stacking and Angle Limits

Information on stacking restrictions and safe operating angles for the machine.

Lifting Procedures

Safe methods and precautions for lifting the welding equipment.

Installation Considerations

High Altitude Operation Adjustments

Adjustments for welder output derating at higher altitudes.

Towing and Vehicle Mounting

Guidelines for safely towing and mounting the equipment on vehicles.

Pre-Operation Engine Setup

Procedures for engine oil levels and checking before initial operation.

Engine Preparation and Break-in

Fueling and Cooling System

Proper fueling procedures and cooling system maintenance for the engine.

Engine Break-in Procedure

How to properly break in the engine for optimal longevity and performance.

Battery Installation and Safety

Steps and warnings for connecting the battery correctly and safely.

Electrical Connections and Grounding

Welding Output Cable Sizing

Recommended cable sizes for electrode and work cables based on length and current.

Machine Grounding Requirements

Proper grounding procedures for the welder frame and connected equipment.

Operating Instructions Overview

General Machine Description

Overview of the SAE-500 as a diesel engine driven DC welder with AC auxiliary power.

Additional Safety Notes

Further safety considerations for operating the welder, including door closure.

Welder Applications and Features

Recommended Welding Applications

Primary uses for stick welding and optional CV adapter for semi-automatic welding.

Auxiliary Power Capabilities

Details on the 3KW, 115/230 VAC auxiliary power output and receptacles.

Key Design Features

Highlights stick welding benefits, remote control, engine features, and fuel capacity.

Understanding Duty Cycle

Explanation of duty cycle as a percentage of load within a 10-minute period.

Engine and Welder Controls

Engine Control Functions

Description of ignition, idler switch, gauges, and engine protection system.

Welder Control Adjustments

Explanation of polarity switch and how to adjust welding current using Job Selector and Current Control.

Operating the Welder Controls

Setting Welding Parameters

Step-by-step guide on setting the Job Selector and Current Control for desired welding output.

Remote and Auxiliary Power Controls

Information on using remote control and auxiliary power receptacles.

Engine Operation Procedures

Starting the Engine

Detailed steps for starting the engine, including pre-operation checks and glow plug use.

Cold Weather Starting & Stopping

Special considerations for starting in cold weather and proper engine shutdown procedures.

Fuel Consumption Data

Typical Fuel Usage Scenarios

Table showing expected fuel consumption for various operating loads and conditions.

Available Accessories

Welding and Trailer Accessories

Details on TIG modules, trailers, and related kits for enhancing functionality.

Electrical and Safety Accessories

Information on GFCI receptacles, adapters, and cable kits for safety and connectivity.

Maintenance Schedule and Tasks

Routine Daily Maintenance

Daily checks including fuel refill, oil level, and air filter cleaning.

Periodic Maintenance Procedures

Recommended cleaning, brush inspection, and belt checks at regular intervals.

Bearing Lubrication

Guidelines for greasing bearings, emphasizing cleanliness to prevent damage.

Component Maintenance Details

Commutator and Brush Care

Inspection and cleaning of commutators, slip rings, and brushes for optimal performance.

Cooling System and Fuel Filter Service

Maintenance for the radiator cooling system and the fuel pre-filter/water separator.

Maintenance Parts and Procedures

Engine Maintenance Parts

List of replacement parts for engine air filter, fan belt, and fuel/oil filters.

GFCI Receptacle Testing

Step-by-step instructions for testing and resetting the Ground Fault Circuit Interrupter receptacle.

Troubleshooting Guide Introduction

Using the Troubleshooting Section

How to diagnose and resolve machine malfunctions using the problem/cause/action format.

Troubleshooting Common Issues

Maintaining Welding Heat Output

Diagnosing and fixing issues where the machine fails to maintain consistent welding heat.

Troubleshooting Performance Problems

No Current Generation Issues

Steps to troubleshoot why the welder runs but fails to generate current.

Addressing Arc Spatter

Identifying causes and solutions for a loud and excessively spattering welding arc.

Troubleshooting Control and Accuracy

Welding Current Adjustment Issues

Diagnosing why welding current differs from dial indication or if the engine stalls.

Loss of Output Control

Troubleshooting when the welder has output but lacks control, often related to switch position.

Troubleshooting Auxiliary Power

Auxiliary Power Output Problems

Diagnosing and resolving issues where no auxiliary power is available from the receptacles.

Wiring Diagrams

SAE 500 / SAE 500 SD Diagram (Code 11476)

Detailed schematic illustrating the electrical connections and components of the SAE 500 welder.

Wiring Schematics

SAE 500 - Kubota Diagram (Code 12515)

Electrical schematic for the SAE 500 with Kubota engine, showing component interconnections.

Machine Dimensions and Layout

Dimensional Drawings

Visual representation of the machine's physical dimensions and key measurements.

Customer Assistance Policy

Lincoln Electric Support Information

Details on Lincoln Electric's approach to customer advice and support for their products.

Need help?

Do you have a question about the Vantage 410 and is the answer not in the manual?

Questions and answers