Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Summarization of Contents

Introduction to Nanni Marine Engines Operator Manual

Engine Identification and Serial Numbers

Importance of recording engine serial numbers and option codes for service.

Manual Content and User Guidance

Manual Updates and Information Sources

Information is based on current data; updates may occur without notice.

Safety Signals and Alert System

Safety Information and Label Compliance

Alerts to potential injury; follow recommended practices and safety labels.

Engine and Genset Safety Icon Guide

Understanding Common Safety Icons

Illustrates icons for oil drain, electrical hazards, hot parts, pressurized fluids, and rotating parts.

General Safety Precautions for Operation

Safe Maintenance and Workplace Practices

Guidelines for maintaining clean work areas, using protective clothing, and safe tool usage.

Safe Servicing and Operational Safety Procedures

Noise, Electrical, and Guard Safety

Addresses noise protection, genset power handling, and the importance of guards.

Hazard Avoidance: Drivelines and Fluids

Safety in Paint Removal and Heat Exposure

Precautions during paint removal and avoiding heat near pressurized fluid lines.

Electrical Safety and Fuel Handling Precautions

Starting Fluid and Battery Safety Measures

Safe usage of starting fluid and precautions for handling batteries to prevent hazards.

Battery Safety and Winterization Measures

General Safety and Accident Prevention

Ensuring safe operation, checking safety systems, and preventing accidents.

Fuel Types and Contamination Risks

Winter Diesel and Fuel Quality Standards

Properties of winter diesel fuel and importance of fuel quality for engine longevity.

Fuel Impurities and Lubricant Handling

Lubricant Recommendations and Generalities

Guidance on selecting appropriate oils and general lubrication practices.

Oil Viscosity and API/ACEA Standards

Diesel Sulphur Content Impact on Maintenance

Effect of fuel sulphur content on oil and filter intervals; BioDiesel blend considerations.

Coolant Types and Maintenance

Water Quality for Cooling System

Minimum water specifications required for use in the cooling system.

Coolant Options and Freeze Protection

Coolant Quantity and Warm Climate Operation

Required coolant quantity versus system capacity; operation in warm climates.

Safe Disposal of Waste Fluids

Proper Waste Handling Procedures

Use appropriate containers, wear protective gear, and protect the environment.

Annex: Glycol Volume for Freeze Protection

Table Correlating Glycol Volume and Freezing Point

Table correlating glycol volume percentage with freezing point and cooling system capacity.

Engine Identification and Homologation Details

Understanding Engine Homologation Standards

Explains engine certification for emissions and requirements for maintaining compliance.

Engine Responsibility and Warranty Terms

California Proposition 65 Warnings

Health warnings related to engine exhaust and battery components as per California law.

Introduction to Nanni Instrument Panels

Types of Nanni Instrument Panels

Displays and describes panels with and without key ignition systems.

C4 Panel Components and Connections

Coolant Temperature and Battery Charge Indicators

Explains the function of the coolant temperature and battery charge warning lamps.

Engine Status Indicators: Preheating and Oil Pressure

Water in Fuel Filter Alarm Function

Explains the alarm for water in the fuel filter and necessary actions.

C5 Panel Instruments and Displays

Alternator Charge and Starter Switch Functions

Explains the alternator charge indicator and the operation of the starter switch.

Engine Fluid Level and Temperature Indicators

Trim Indicator Operation and Use

Describes the stern drive trim indicator and its effect on boat performance.

Rudder Indicator and Electronic Systems

Nanni SI.4 Electronic Display System

Details the SI.4 electronic control display connected to the engine.

Nanni Control Panel Compatibility Guide

Table Showing Control Panel Model Compatibility

Table showing compatibility of various Nanni control panels with engine models.

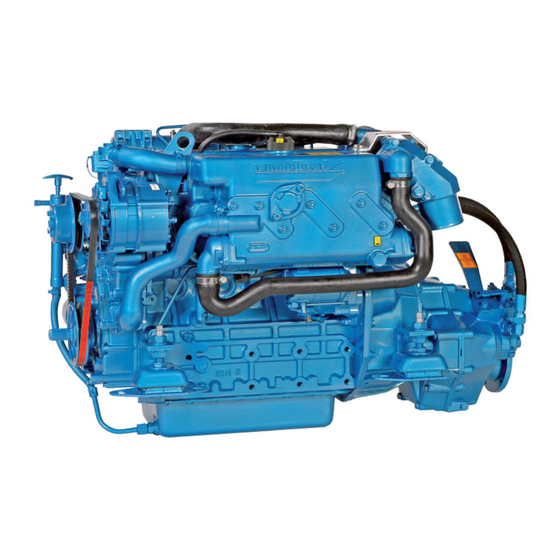

Engine Components Overview

Main Engine Component Identification

Lists the primary components of the engine for reference.

Detailed List of Engine Main Components

Component Part Number Listing

Provides a numbered list of all main engine components with part numbers.

Engine Component Diagrams for N4.65

Visual Diagrams of N4.65 Engine Components

Illustrates the location of major components on the N4.65 engine.

Engine Component Diagrams for N4.80

Visual Diagrams of N4.80 Engine Components

Illustrates the location of major components on the N4.80 engine.

Before Starting: Installation and System Checks

Fuel and Raw Water System Operation

Explains how the fuel and raw water systems draw and supply fluids.

Pre-Start Checks and Safety Warnings

Engine Starting Procedures and Cold Weather Use

Steps for starting the engine and guidelines for operating in cold temperatures.

Engine Start Procedures with Key Ignition

Engine Start Procedures Without Key Ignition

Instructions for starting the engine using a button-based ignition system.

Starting Electronic Type 5 Engines

Ensuring Proper Engine Start-up and Warm-up

Post-start checks for oil pressure and coolant temperature, and initial warm-up.

Starting with Booster Batteries and Troubleshooting

Engine Idling Best Practices

Guidance on proper engine idling to prevent fuel dilution and deposit buildup.

Normal Engine Operation and Monitoring

Engine Break-in Period and Power Take-Off

Procedures for the engine's break-in period and the use of Power Take-Off (PTO) systems.

Remote Control System Operation

Boat Handling and Operation Monitoring

Factors affecting boat behavior and importance of monitoring instruments during running.

Setting Cruising Speed and Efficiency

Maneuvering Techniques and Safety

Procedures for maneuvering the boat, especially twin-engine setups and speed shifting.

Engine Use While Sailing

Trolling Valve System Usage

How to use the trolling valve to control propeller speed for slow trolling.

Engine Shutdown and Cooling Down

Post-Shutdown Checks and Precautions

Checking for leaks after shutdown and precautions regarding hot engine parts.

Engine Care During Anchoring and Storage

Winter Precautions for Raw Water Systems

Draining raw water systems to prevent freezing damage.

Introduction to Engine Maintenance

Importance of Regular Maintenance Checks

Emphasizes the role of regular checks and recommended authorized workshops.

Comprehensive Maintenance Schedule

A Detailed Schedule Outlining Maintenance Tasks

A detailed schedule outlining maintenance tasks and intervals for all engine systems.

General Maintenance Safety and Procedures

Control Cable Inspection and Adjustment

Guidance on inspecting, adjusting, and replacing engine control cables.

Turbocharger Operation and Service

Turbocharger Heat and Maintenance Limitations

Warnings about hot turbochargers and limitations for end-user service.

Exhaust System Maintenance and Inspection

Ensuring Proper Exhaust Gas Discharge

Ensuring proper exhaust gas discharge and inspecting for leaks or deposits.

Air Intake System Performance

Air Filter Cleaning and Oiling Procedure

Step-by-step instructions for cleaning and properly oiling the air filter.

Fuel System Maintenance and Safety

Draining Water from Fuel Prefilter

Procedure for draining water and impurities from the fuel prefilter.

Fuel Filter Replacement Procedure

Bleeding Air from Mechanical Fuel Pump System

Process for removing air from the fuel system after filter replacement.

Bleeding Air with Electric Fuel Feed Pump

Instructions for Bleeding Electric Fuel Systems

Instructions for bleeding air from fuel systems using an electric fuel feed pump.

Engine Oil Level Check and Addition

How to Check Engine Oil Level and Add Oil

How to check engine oil level and add oil if necessary, following safety guidelines.

Engine Oil Draining Procedure

Engine Oil Filter Replacement

Instructions for removing and replacing the oil filter, including sealing and lubrication.

Cooling System Overview and Function

Cooling System Safety and Water Usage Guidelines

Safety precautions for the cooling system and proper use of water and antifreeze.

Coolant Level Check Procedure

Water Boiler Integration and Coolant Expansion

Information on connecting a water boiler and understanding coolant expansion.

Draining the Coolant Circuit

Filling the Coolant System Safely

Procedure for filling the cooling system with coolant mix, including boiler integration.

Raw Water System Safety Precautions

Zinc Anode Inspection and Siphon Breaker Function

Checking zinc anodes and the importance of the siphon breaker for preventing water entry.

Raw Water Pump Impeller Maintenance

Procedure for Impeller Extraction and Replacement

Procedure for extracting, inspecting, and replacing the raw water pump impeller.

Cleaning the Raw Water Filter

Draining the Raw Water System

Procedure for draining the raw water system, especially when the boat is out of water.

Raw Water System Cleaning Procedure

Frost Protection for Raw Water Systems

Steps to protect the raw water circuit from freezing during long-term storage.

Electrical System Safety and Components

Battery Maintenance and Cable Handling

Keeping batteries clean, disconnecting starter cables, and battery replacement guidelines.

Battery Cable Connection Procedure

Battery Electrolyte Level Check

How to check and maintain battery electrolyte level and specific gravity.

Alternator Belt Inspection and Tension

Fuse Checks and Replacement Procedures

Identifying and replacing blown fuses to troubleshoot electrical issues.

Fuse Identification and Types

Fuse Ratings for N4.65-N4.80 Engines

Table detailing fuse types, ratings, and their applications for specific engines.

Miscellaneous Maintenance: Camshaft Timing

Camshaft Timing System Description

Explains that camshaft timing is gear-driven and service-free.

Long Term Engine Storage Procedures

Detailed Long Term Storage Steps

Comprehensive list of tasks including draining fluids, cleaning, and protection.

Restarting Engine and Battery Storage

Battery Care During Storage

Adjusting electrolyte level and recharging batteries during storage.

Engine Troubleshooting Guide

Identifying Potential Causes of Engine Issues

Lists common engine problems and their probable causes, referencing a subsequent page.

Comprehensive Troubleshooting Causes

Detailed List of Engine Failure Causes

Provides a numbered list of potential causes for various engine malfunctions.

N4.65 Technical Data Sheet

General Engine Characteristics (N4.65)

Details general data like engine base, configuration, type, and displacement.

Lubrication System Specifications (N4.65)

Provides idle and rated oil pressure specifications for the N4.65 engine.

N4.65 Performance and Fuel System Data

Lubrication and Performance Data (N4.65)

Covers oil capacity, tilt limits, torque, and power output for N4.65.

Fuel System Specifications (N4.65)

Details fuel consumption, restrictions, and pressure for the N4.65 engine.

N4.65 Cooling, Exhaust, and Intake Systems

Cooling System Specifications (N4.65)

Provides flow rates, heat rejection, thermostat data, and coolant capacity.

Exhaust and Air Intake Systems (N4.65)

Details exhaust gas flow, back pressure, and air intake parameters.

N4.65 Electrical, Installation, and Ratings

Electrical System Components (N4.65)

Lists alternator, starter, and battery specifications for the N4.65 engine.

Installation Tips and Usage Ratings (N4.65)

Provides installation advice, weight data, and application ratings for the N4.65.

N4.80 Technical Data Sheet

General Engine Characteristics (N4.80)

Details general data like engine base, configuration, type, and displacement.

Lubrication System Specifications (N4.80)

Provides idle and rated oil pressure specifications for the N4.80 engine.

N4.80 Performance and Fuel System Data

Lubrication and Performance Data (N4.80)

Covers oil capacity, tilt limits, torque, and power output for N4.80.

Fuel System Specifications (N4.80)

Details fuel consumption, restrictions, and pressure for the N4.80 engine.

N4.80 Cooling, Exhaust, and Intake Systems

Cooling System Specifications (N4.80)

Provides flow rates, heat rejection, thermostat data, and coolant capacity.

Exhaust and Air Intake Systems (N4.80)

Details exhaust gas flow, back pressure, and air intake parameters.

N4.80 Electrical, Installation, and Ratings

Electrical System Components (N4.80)

Lists alternator, starter, and battery specifications for the N4.80 engine.

Installation Tips and Usage Ratings (N4.80)

Provides installation advice, weight data, and application ratings for the N4.80.

EPA Emissions Warranty and Coverage

Scope and Coverage of Nanni Warranty

Details warranty for new diesel engines sold in the USA, covering emission control components.

EPA Warranty Application and Labeling

Explains EPA/CARB warranty applicability and the importance of the emission control label.

Warranty Period Determination

Defines how the warranty period starts and lists warranty terms for various engine models.

Warranty Limitations and Customer Assistance

Engine Responsibility and Environmental Impact

Nanni's commitment to minimal environmental impact and user's role.

Customer Support and Dealer Contact

Information on seeking assistance for Emission Control Systems from dealers.

Need help?

Do you have a question about the N4.80 and is the answer not in the manual?

Questions and answers