Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summarization of Contents

Legal Information

Safety and Operational Guidelines

Manual notices for personal safety and property damage prevention, personnel qualifications, and proper product use.

Legal Notices and Trademarks

Information on trademarks, disclaimer of liability, and publication review.

Preface

Purpose of Documentation

Provides module-specific information on wiring, diagnostics, and technical specifications.

Document Conventions and Notes

Explains how notes and other marked information are presented in the manual.

Siemens Industry Online Support Resources

Accessing product support, application examples, services, and forums online.

Documentation Guide

Manual Structure and Resources

Explains the three-area arrangement of SIMATIC ET 200SP documentation and lists general information resources.

mySupport Platform Overview

Personal workspace for managing support requests, filters, favorites, and downloads.

Support and Configuration Tools

Details application examples, selection tools (TIA), automation tools, and network analysis tools.

Product Overview

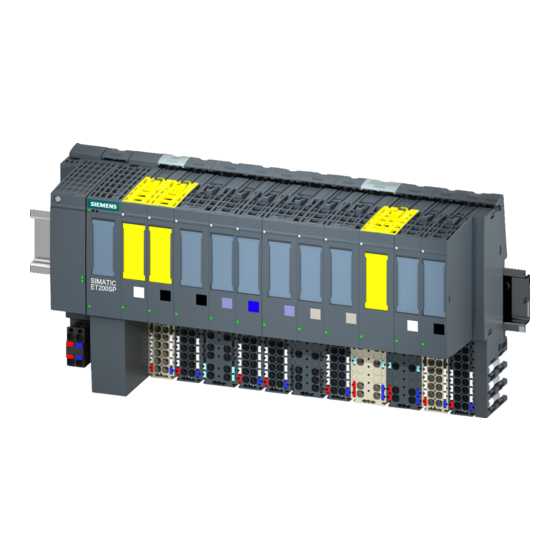

Module Properties Overview

Details the article number and provides a visual overview of the TM PTO 2x24V module with labeled components.

Module Introduction and Properties

Introduces the module's function and lists its key technical properties and interfaces.

Supported Functions and Accessories

Details supported functions, configurability, and lists required accessories like BaseUnits.

Module Functions: Pulse Train Output (PTO)

Explains the Pulse Train Output (PTO) interface, its applications, and control methods.

PTO Signal Types

Describes the Pulse (P) and Direction (D) signal type for PTO functionality.

PTO Phase-Shifted Signal Types (A/B)

Details the PTO signal types using A/B phase-shifted and A/B phase-shifted quadruple signals.

Connecting

Pin Assignment and BaseUnit

Details the module's pin assignment, the necessary BaseUnit, and supply voltage connection.

BaseUnit Terminal Assignment Table

Provides a detailed table of terminal assignments for the example BaseUnit BU15-P16+A0+2B.

Circuit Diagram for Module Connections

Illustrates the module's circuit diagram, including electrical isolation and shield grounding connections.

24V Pulse Output and Digital Input Signals

Describes 24V pulse output signals (P/A, D/B) and digital inputs (RS, MI, DR) and their functions.

Digital Input Delay and Output ED

Details input delay configuration for digital inputs and the function of the digital output ED for drive enable.

Configuring and Address Space

Module Configuration Introduction

Explains how the technology module is configured and parameterized using software and user programs.

System Environments for Configuration

Outlines system environments for module configuration, including centralized and distributed operations.

Control Using Technology Objects

Guides on configuring the module with axis technology objects like TO_SpeedAxis, TO_PositioningAxis.

Hardware Support Package (HSP) and GSD Files

Details integration via HSP and provides links for downloading GSD files for PROFINET IO and PROFIBUS DP.

Parameter Setting

Methods for Parameter Setting

Describes parameter setting using STEP 7 (TIA Portal), and GSD files for PROFINET IO and PROFIBUS DP.

Programmable Parameters of TM PTO 2x24V

Lists all programmable parameters, their value ranges, and their scope (module or channel).

Detailed Parameter Descriptions

Provides in-depth explanations for key parameters like Potential group, Signal type, Reference speed, and maximum speed.

Address Space

Module Address Space Allocation

Specifies the input and output address ranges per channel and the total address range for the module.

Control and Feedback Interface

Control Interface Overview and Technology Objects

Explains the control interface and its use with technology objects like TO_SpeedAxis, TO_PositioningAxis.

Assignment of the Control Interface

Details the control interface assignment based on PROFIdrive telegrams, including control word 1.

Description of Control Bits (STW1)

Explains the meaning and function of control bits within STW1, such as Control_by_PLC and Enable_Operation.

Description of Control Bits (Continued)

Continues the description of control bits, including Fault_Acknowledge, NSOLL_A, and Master_Sign-Of-Life.

Description of Control Bits (Further)

Details control bits like Activate_Parking_Sensor, Command Requests, and Function Requests.

Assignment of the Feedback Interface

Details the feedback interface assignment, including status word 1 (ZSW1) and encoder status.

Description of Feedback Bits (ZSW1, ZSW2, G1 ZSW)

Explains feedback bits in ZSW1, ZSW2_ENC, and G1_ZSW related to module status and sensor feedback.

Description of Feedback Bits (Values)

Describes feedback bits related to values like Value_1_Active, Value_2_Active, G1_XIST1, and G1_XIST2.

Error Codes for G1_XIST2

Lists error codes for G1_XIST2, their meanings, and remedies for sensor errors, reference marks, and input acquisition.

Reference Mark Search Sequence

Illustrates the sequence for detecting and reading the reference mark using specific control bits and mode settings.

Measurement on the Fly Sequence

Illustrates the sequence for acquiring and reading measuring input values via digital input CHn.MI.

Pulse Output Enable State Diagram

Presents the state diagram for enabling the pulse output, detailing transitions and feedback bit conditions.

Procedure for Enabling Pulse Output

Provides a step-by-step procedure to enable the pulse output by setting specific control bits.

Reaction to CPU STOP

Describes the module's behavior when the CPU transitions to STOP mode, including Coast Stop and interface status.

Isochronous Mode

Isochronous Mode Data Processing

Explains the PROFINET 'Isochronous mode' function for synchronized data processing and pulse output adjustment.

Interrupts and Diagnostic Alarms

LED Status and Error Displays

Shows the location of LEDs on the TM PTO 2x24V module and provides a diagram for identification.

Meaning of LED Displays

Explains the diagnostic meanings of the DIAG and PWR LEDs, and the status indication for channel LEDs.

Enabling Diagnostic Interrupts

Details how to enable diagnostic interrupts and lists the types of diagnostic interrupts the module can trigger.

Reactions to Diagnostic Interrupts

Describes the system's reaction when a diagnostic interrupt occurs, including CPU and module behavior.

Diagnostic Alarms List and Remedies

Lists diagnostic alarms, their error codes, meanings, and specific corrective actions for each.

Diagnostic Alarms Details and Cross-Channel Effects

Provides further details on diagnostic alarms and explains cross-channel diagnostics for digital outputs.

Technical Specifications

Module Identification and Compatibility

Specifies the article number, product type, compatibility with engineering tools, and functions.

Power and Address Space Specifications

Details supply voltage, load voltage, input current, power loss, and address space allocation.

Digital Input Specifications

Specifies the number of digital inputs, their parameterizability, and input characteristic curve type.

Parameterizable Digital Input and Output Functions

Details parameterizable input functions (Sync, Probe, Drive Ready) and output functions (PTO signal types).

Input Voltage, Current, Delay, and Cable Length

Specifies input voltage ratings, input current, input delay options, and maximum cable lengths.

Digital Output Specifications

Details number of digital outputs, current sourcing/sinking, parameterization, and short-circuit protection.

Output Switching Capacity and Load Range

Specifies maximum switching capacity for various loads and the load resistance range for digital outputs.

Output Voltage, Current, and Switching Frequency

Details output voltage, rated output current, permissible range, and maximum switching frequencies.

Interrupts, Diagnostics, and Status LEDs

Lists available alarms, diagnoses (supply voltage, short-circuit), and diagnostic LED indicators.

Potential Separation, Isolation, and Ambient Conditions

Details electrical isolation, ambient temperature limits, and altitude restrictions for module operation.

Decentralized Operation Compatibility and Dimensions

Lists compatibility with various automation systems and provides module dimensions and weight.

Digital Output Current Derating Information

Explains how to derate the total current for digital outputs based on ambient temperature and mounting position.

Parameter Data Record

Parameter Assignment and Data Record Structure

Describes changing module parameters using WRREC and the structure of data record 128.

Data Record 128 Structure (Overall Module)

Details the structure of data record 128, including header, version, length, and reserved fields for the module.

Data Record 128 Structure (Channel Parameters)

Details the structure of data record 128 for channel parameters: basic, operating mode, digital inputs, and values.

Maximum Speed Calculation

Shows the calculation for the value range of the maximum speed based on signal evaluation and increments.

Parameter Validation Error

Parameter Validation Error Handling

Explains how parameter values are checked before transfer and how the module handles invalid data.

WRREC Instruction for Parameter Changes

Describes using the WRREC instruction to change parameters while the CPU is in RUN and error handling.

WRREC Example and Status Output Interpretation

Provides an example of WRREC execution with invalid data and explains how to interpret the STATUS output.

Error Codes for Parameter Validation

Lists module-specific error codes for parameter data record validation, their meanings, and corrective actions.

Need help?

Do you have a question about the 6ES7138-6EB00-0BA0 and is the answer not in the manual?

Questions and answers