Table of Contents

Advertisement

INSTRUCTION MANUAL

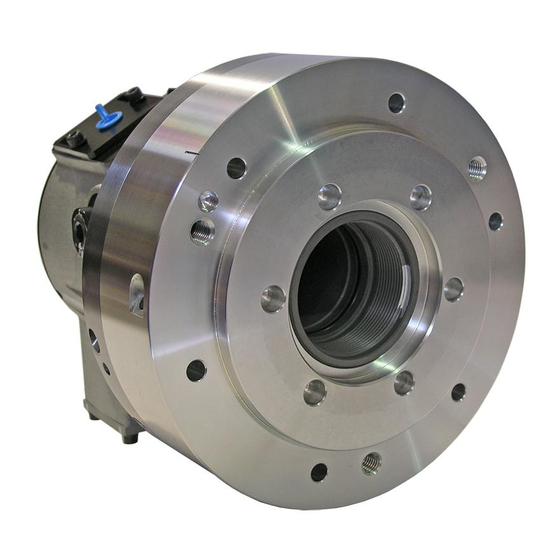

SR

HIGH SPEED ROTARY HYDRAULIC

CYLINDER OPEN CENTER

・This instruction manual is for production engineers and

maintenance personnel in charge of operation of this product.

When a beginner uses this product, receive instructions from

experienced personnel, the distributor or our company.

・Before installing, operating or maintaining this equipment,

carefully read this manual and the safety labels attached to

the equipment. Failure to follow these instructions and safety

precautions could result in serious injury, death, or property

damage.

・Store this manual near equipment for future reference.

・If any questions related to safety arise about this manual,

please confirm them with the distributor or our company.

Kitagawa Corporation

77-1,Motomachi,Fuchu-shi,Hiroshima,726-8610,Japan

type

Te l . +81-847-40-0561

Fax. +81-847-45-8911

Version 1.06 (2019.09.03)

Original instructions

Advertisement

Table of Contents

Summarization of Contents

Structural Drawing and Parts List

Type display

Explains the type display system for SR cylinders and its components.

Structural drawing

Presents a structural diagram of the SR type cylinder and its main parts.

Scope of product

Clarifies that this instruction manual covers the cylinder part of the product.

Parts list

Provides a detailed list of parts for the cylinder with corresponding numbers and quantities.

Important Safety Precautions

Power Off Before Maintenance

Turn off the main power supply before performing cylinder maintenance or adding oil.

Close Door Before Spindle Rotation

Ensure the machine door is closed before rotating the spindle for safety.

Hydraulic Power During Spindle Rotation

Avoid turning off hydraulic power or operating valves during spindle rotation to maintain grip.

Adhere to Maximum Rotation Speed

Do not exceed the maximum allowable rotation speed of the chuck to prevent parts from flying out.

Respect Maximum Input Force

Ensure chuck input force, including piston thrust and draw pipe pull, does not exceed the maximum allowable limit.

Inside Diameter Gripping Pressure Limit

When gripping internally, hydraulic pressure must be 1/2 or less of the maximum allowable input.

SR Cylinder Pressure Setting

Adjust setting pressure for SR cylinders based on specific model requirements to prevent damage.

Attach Cylinder Covers

Ensure protective covers are attached to the cylinder periphery before operation to prevent entanglement.

Bolt Tightening Torque

Always tighten bolts to the specified torque using the provided bolts to prevent breakage and flying parts.

Chuck and Cylinder Compatibility

Ensure chuck and cylinder compatibility to prevent breakage and flying parts due to high-pressure issues.

Solenoid Valve for Gripping Position

Use a solenoid valve that maintains gripping position when no current is carried for safety.

Draw Pipe Strength and Installation

Ensure adequate draw pipe strength and proper installation to prevent loss of gripping force and flying work.

Do Not Modify Cylinder

Avoid modifying the cylinder as it can cause damage, oil leakage, fire, or loss of gripping force.

Avoid Rotation Without Hydraulic Pressure

Never rotate the cylinder without hydraulic pressure to prevent seizing and loss of gripping force.

Periodic Hydraulic Oil Addition

Regularly add hydraulic oil and use a filter to maintain cylinder function and prevent seizing.

Clean Piping Before Assembly

Thoroughly clean pipes before assembly to prevent oil leakage, fire, and seizing due to foreign matter.

Avoid Operation Under Influence

Refrain from operating the machine while under the influence of alcohol or medication to prevent accidents.

Appropriate Work Attire

Do not wear loose clothing, jewelry, or gloves that can be caught in the machine during operation.

Attaching Non-Kitagawa Parts

Consult page 26 for attaching parts not manufactured by Kitagawa, ensuring their safety for usage conditions.

Vertical Cylinder Installation Prohibited

Do not install the cylinder vertically as it can cause oil leakage and potentially result in a fire.

Specifications

Specifications table

Presents a detailed specification table for various SR cylinder models, including dimensions and performance data.

Hydraulic Oil

Recommended Hydraulic Oil

Use hydraulic oil with a viscosity of 32cSt at 40°C (ISO VG32 equivalent) for optimal cylinder operation.

Hydraulic Oil Replacement Schedule

Replace the hydraulic oil approximately every six months for consistent performance and longevity.

Trial Operation

Trial Operation Steps

Guides through essential steps for initial trial operation, including voltage, pressure, and speed checks.

Troubleshooting Cylinder Operation Issues

Provides steps to resolve issues when the cylinder cannot be operated during trial or normal operation.

Product Usage Description

Explains the product's function as a hydraulic device to control power chucks on lathes and rotary tables.

Maintenance and Inspection

Maintenance and inspection of the cylinder

Details on cylinder maintenance and inspection; advises returning to the company for repair if disassembled.

Maintenance and inspection of hydraulic unit

Instructions for cleaning the suction strainer and replacing hydraulic oil for the hydraulic unit.

List of seals to use

Provides a comprehensive list of O-rings and seals required for maintenance, referenced by figure and type.

Malfunction and Countermeasures

In the case of malfunction

Provides a table listing defective symptoms and corresponding measures for troubleshooting cylinder malfunctions.

Where to contact in the case of malfunction

Advises contacting the distributor or branch office for assistance with any malfunctions that cannot be resolved.

Coolant Collector

Outline

Describes the coolant collector's function and attachment to the cylinder for collecting coolant from the draw pipe.

Type and applicable cylinder

Lists different coolant collector types and their corresponding applicable cylinder models.

Attachment

Provides instructions on how to attach the coolant collector main body and the detectable plate to the cylinder.

Positional adjustment of proximity switch

Details the procedure for adjusting the position of proximity switches on the coolant collector.

Precautions

Offers important precautions regarding coolant overflow, cleaning, and protecting proximity switches from coolant and chips.

Parts list

Presents a parts list for the coolant collector assembly, including part names, quantities, and reference numbers.

Attachment

Outline drawing of attachment

Illustrates the overall hydraulic circuit and mechanical arrangement for attaching the cylinder to a machine.

Production and attachment of cylinder adapter

Provides guidance on producing and attaching the cylinder adapter, including run-out measurements and setscrew use.

Production and attachment of draw pipe

Details the process for producing and attaching the draw pipe, emphasizing degreasing, adhesive application, and screw-in depth.

Attachment of cylinder

Explains the procedure for safely attaching and detaching the cylinder using lifting belts and proper mounting.

Tightening torque of the cylinder attaching bolt

Specifies the correct tightening torque for cylinder attaching bolts and cautions against using incorrect bolts.

Attachment of parts other than parts manufactured by Kitagawa Corporation

Guidance for attaching non-Kitagawa parts, including stoppers and work stops, with safety warnings.

About Hydraulic Circuit Design

Failsafe Hydraulic Circuit Design

Design hydraulic circuits for ease of operation and failsafe mechanisms to prevent accidents during blackouts.

Other information

About standards and orders

Lists the standards and directives this product is based on, including EC Machinery Directive and ISO standards.

Information about markings of product

Explains the markings found on the product, including caution notes and specification labels.

About disposal

Provides guidance on the ultimate disposal of the product according to national laws and regulations.

Need help?

Do you have a question about the SR1781 and is the answer not in the manual?

Questions and answers