Table of Contents

Advertisement

INSTRUCTION MANUAL

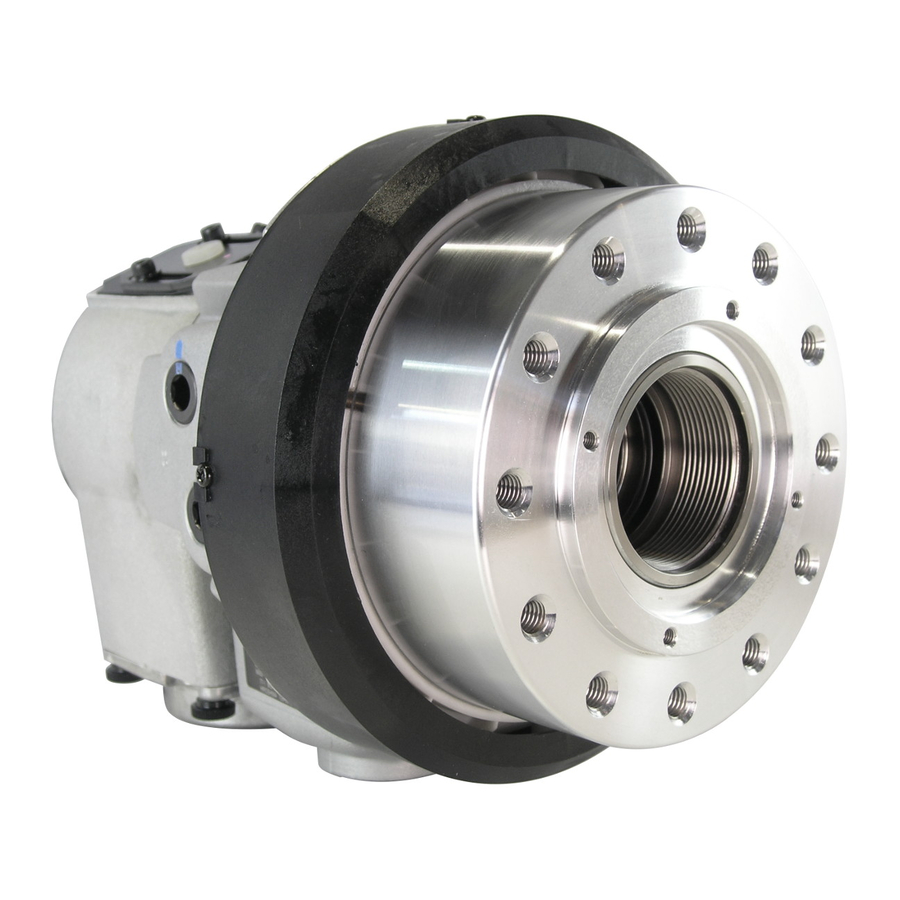

HIGH SPEED ROTARY HYDRAULIC

CYLINDER OPEN CENTER

・This instruction manual is for production engineers and

maintenance personnel in charge of operation of this product.

When a beginner uses this product, receive instructions from

experienced personnel, the distributor or our company.

・Before installing, operating or maintaining this equipment,

carefully read this manual and the safety labels attached to

the equipment. Failure to follow these instructions and safety

precautions could result in serious injury, death, or property

damage.

・Store this manual near equipment for future reference.

・If any questions related to safety arise about this manual,

please confirm them with the distributor or our company.

Kitagawa Corporation

77-1,Motomachi,Fuchu-shi,Hiroshima,726-8610,Japan

S

type

Te l . +81-847-40-0561

Fax. +81-847-45-8911

Version 1.10 (2019.09.03)

Original instructions

Advertisement

Table of Contents

Need help?

Do you have a question about the S1036 and is the answer not in the manual?

Questions and answers