Table of Contents

Advertisement

Quick Links

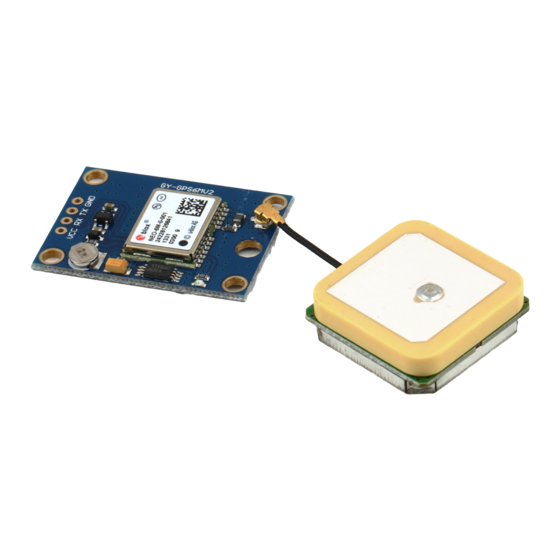

LEA-6 / NEO-6

u-blox 6 GPS Modules

Hardware Integration Manual

Abstract

This document describes the features and specifications of the cost

effective and high-performance LEA-6 and NEO-6 GPS modules

featuring the u-blox 6 positioning engine.

These compact, easy to integrate stand-alone GPS receiver modules

combine exceptional GPS performance with highly flexible power,

design, and connectivity options. Their compact form factors and

SMT pads allow fully automated assembly with standard pick &

place and reflow soldering equipment for cost-efficient, high-

volume production enabling short time-to-market.

www.u-blox.com

Downloaded from

DatasheetLib.com

- datasheet search engine

Advertisement

Table of Contents

Summarization of Contents

Preface

u-blox Technical Documentation

Lists additional manuals and technical resources for u-blox products.

How to Use This Manual

Provides guidance on navigating the document's modular structure and understanding symbols.

Technical Support

Worldwide Web Support

Information on accessing product data, technical documents, and FAQs via the u-blox website.

Email Support

How to contact technical support offices via email for assistance.

Information for Technical Support

Details needed when contacting support, including receiver type and problem description.

1 Hardware Description

1.1 Overview

Introduces the LEA-6 and NEO-6 modules as standalone GPS receivers.

1.2 Architecture

Describes the two main functional parts: RF and Baseband sections of the modules.

1.3 Power Management

Details the three power supply pins (VCC, V_BCKP, VDDUSB) and their functions.

1.4 Antenna Supply - V_ANT (LEA-6)

Explains the V_ANT pin for active antenna supply and supervision on LEA-6.

1.5 System Functions

Covers system functions like EXTINT pin and system monitoring.

1.6 Interfaces

Discusses serial communication interfaces: UART, USB, DDC, and SPI.

1.7 I/O Pins

Describes various input/output pins like RESET_N, EXTINTO, and configuration pins.

2 Design-in

2.1 Design-in Checklist

A checklist covering power supply, layout, and design considerations for optimal performance.

2.1.1 Layout Design-in Checklist

Key items for checking PCB layout to ensure optimal performance and avoid redesigns.

2.1.2 Design Considerations

Essential functions and pins to consider for a minimal u-blox 6 GPS module design.

2.2 LEA-6 Design

Specific design aspects for LEA-6 modules, including passive antenna setup.

2.2.1 LEA-6 Passive Antenna Design

Minimal setup for a PVT GPS receiver using a LEA-6 module with a passive antenna.

2.2.2 Pin Description for Antenna Designs (LEA-6)

Detailed pin descriptions for antenna designs specifically for LEA-6 modules.

2.3 NEO-6 Design

Specific design aspects for NEO-6 modules, including passive antenna setup.

2.3.1 Passive Antenna Design (NEO-6)

Minimal setup for a PVT GPS receiver using a NEO-6 module with a passive antenna.

2.4 Layout

Information on PCB layout for reliable and sensitive GPS system design.

2.4.1 Footprint and Paste Mask

Recommendations for module footprint and paste mask geometry.

2.4.2 Placement

Guidance on optimal receiver placement on the PCB for maximum performance.

2.4.3 Antenna Connection and Grounding Plane Design

Design considerations for connecting antennas and creating grounding planes.

2.4.4 Antenna Micro Strip

Details on calculating and designing antenna micro strips for 50 Ohm impedance.

2.5 Antenna and Antenna Supervisor

Discusses antenna types, gain limits, and the active antenna supervisor circuit.

2.5.1 Passive Antenna

Design considerations for passive antennas, including layout and noise reduction.

2.5.2 Active Antenna (LEA-6)

Integration of active antennas with LEA-6, including biasing and placement.

2.5.3 Active Antenna (NEO-6)

Integration of active antennas with NEO-6, including inductor use for biasing.

2.5.4 Active Antenna Bias Power (LEA-6)

Methods for supplying bias voltage to active antennas on LEA-6.

2.5.5 Active Antenna Supervisor (LEA-6)

Implementation of an active antenna supervisor circuit for fault detection.

3 Product Handling

3.1 Packaging, Shipping, Storage and Moisture Preconditioning

Information on module packaging, shipping, storage, and moisture sensitivity.

3.2 Soldering

Comprehensive guide to soldering processes including paste, reflow, and inspection.

3.2.1 Soldering Paste

Recommendations for "No Clean" soldering paste and stencil thickness.

3.2.2 Reflow Soldering

Guidelines for convection reflow soldering, including temperature profiles.

3.2.3 Optical Inspection

Steps for visually inspecting solder joints and module alignment after soldering.

3.2.4 Cleaning

Discourages cleaning modules and provides reasons why.

3.2.5 Repeated Reflow Soldering

Discourages repeated reflow soldering and upside-down module soldering.

3.2.6 Wave Soldering

Mentions wave soldering for THT components and single process for SMT modules.

3.2.7 Hand Soldering

Guidelines for performing hand soldering on the module.

3.2.8 Rework

Procedures for unsoldering and replacing modules, with warnings.

3.2.9 Conformal Coating

Advises on applying conformal coating and its warranty implications.

3.2.10 Casting

Guidance on casting processes and their warranty impact.

3.2.11 Grounding Metal Covers

Discusses soldering ground strips to EMI covers at customer's risk.

3.2.12 Use of Ultrasonic Processes

Warns against using ultrasonic processes due to potential module damage.

3.3 EOS/ESD/EMI Precautions

Essential guidelines for handling and protecting against Electrostatic Discharge, Overstress, and Interference.

3.3.1 Abbreviations

Refers to Appendix A for a list of abbreviations used.

3.3.2 Electrostatic Discharge (ESD)

Defines Electrostatic Discharge (ESD) as a sudden electric current causing damage.

3.3.3 ESD Handling Precautions

Principles for establishing Electrostatic Protective Areas (EPAs) and handling precautions.

3.3.4 ESD Protection Measures

Specific ESD protection measures for passive and active antennas.

3.3.5 Electrical Overstress (EOS)

Defines Electrical Overstress (EOS) as exceeding maximum input power ratings.

3.3.6 EOS Protection Measures

Recommended EOS protection measures for mixed wireless transceiver designs.

3.3.7 Electromagnetic Interference (EMI)

Explains EMI and recommends grounding, shielding, and filtering measures.

3.3.8 GSM Applications

Addresses challenges with GSM applications, including antenna isolation and jamming.

3.3.9 Recommended Parts

Lists recommended components for ESD/EOS protection and filtering.

4 Product Testing

4.1 u-blox In-Series Production Test

Describes u-blox's automatic test equipment and measurements for ensuring product quality.

4.2 Test Parameters for OEM Manufacturer

Focus areas for OEM manufacturers regarding device sensitivity and host communication.

4.3 System Sensitivity Test

Methods for testing GPS device sensitivity using a 1-channel GPS simulator.

4.3.1 Guidelines for Sensitivity Tests

Step-by-step guide for performing sensitivity tests using a GPS simulator.

4.3.2 'Go/No Go' Tests for Integrated Devices

Simple tests for integrated devices, often involving outdoor signal acquisition.

Appendix

A Abbreviations

Provides a table explaining common abbreviations used in the document.

B Migration to u-blox 6 Receivers

Guidance on migrating from ANTARIS 4 and u-blox 5 designs to u-blox 6 receivers.

B.1 Checklist for Migration

A checklist to help select the optimal u-blox 6 module variant for specific application needs.

B.2 Software Migration

Details differences in software and protocol messages between older and u-blox 6 versions.

B.3 Hardware Migration

Discusses hardware considerations when migrating from ANTARIS 4 and u-blox 5.

B.4 Migration of LEA Modules

Compares pin assignments and voltage thresholds for LEA module migration.

B.5 Migration of NEO Modules

Compares pin assignments and configuration settings for NEO module migration.

C Interface Backgrounder

Explains the I²C compatible Display Data Channel (DDC) interface principles.

C.1 DDC Interface

Explains the I²C compatible Display Data Channel (DDC) interface principles.

C.1.1 Addresses, Roles and Modes

Describes device addressing, roles (master/slave), and modes within the DDC bus.

C.1.2 DDC Troubleshooting

Common questions and considerations for troubleshooting DDC interface implementations.

C.2 SPI Interface

Provides an overview of the Serial Peripheral Interface (SPI) communication protocol.

C.2.1 SPI Basics

Explains the fundamental principles of SPI communication in master/slave modes.

Need help?

Do you have a question about the NEO-6Q and is the answer not in the manual?

Questions and answers