Table of Contents

Advertisement

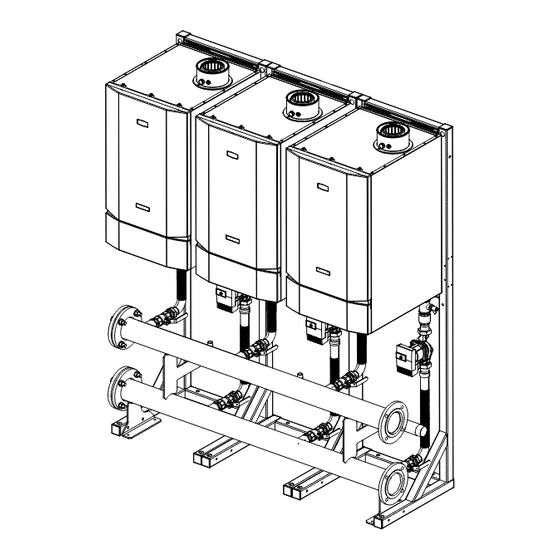

STANDARD HEIGHT

FRAME & HEADER KITS

EVOMAX

30 - 150

30P - 80P

EVOMAX 2

30 - 150

30P - 120P

When replacing any part on this appliance, use only spare parts that you can be assured conform to the safety and performance specification that we

require. Do not use reconditioned or copy parts that have not been clearly authorised by Ideal.

For the very latest copy of literature for specification and maintenance practices visit our website www.idealcommercialboilers.com

where you can download the relevant information in PDF format.

April 2019

UIN 220380 A01

Advertisement

Table of Contents

Summarization of Contents

1 INTRODUCTION

Introduction to Frame & Header Kits

Details the purpose and application of Evomax multiple boiler frame and header kits for spreading heat output.

2 CASCADE SYSTEM DESCRIPTION

Frame and Header Kit Design Options

Explains the side-by-side and back-to-back configuration options for Evomax multiple boiler systems.

Multiple Boiler Installation Overview

Covers installation of 2 to 6 boilers using water and gas headers with various connection types.

Hydronic Isolation: Low Loss Header & Plate Heat Exchanger

Explains the function of low loss headers for flow separation and heat transfer in hydronic systems.

Output Control and Cascade Options

Discusses wiring pumps for controlled pump over-run and optional cascade control accessories.

Gas Supply Configuration

Details gas supply configurations for Natural Gas and LPG/Propane for Evomax and Evomax 2 boilers.

System Assembly Considerations

Provides guidance on locating and securing frames for multi-boiler installations, ensuring stability.

Safe Handling Procedures

Outlines essential safety precautions and techniques for handling and maneuvering boilers and kits.

3 MULTIPLE BOILER SYSTEM COMPONENTS

General System Components

Lists the primary components of multiple boiler systems, including frame kits, headers, and hardware.

Main Water Headers

Describes water flow and return headers sized for different configurations and output requirements.

Gas Header Assembly

Details the custom-manufactured 2" manifold used for gas supply in multi-boiler setups.

Optional Low Loss Headers (Mixing Header)

Explains the features of optional mixing headers, including air vents and drain points.

Boiler Shunt Pump Requirements

Discusses the role of pump kits and external controls in ensuring optimal flow around appliance circuits.

Boiler Connection Kit Components

Details the connection kit components for boiler flow and return, including valves and seals.

Free-Standing Frame Options

Describes options for mounting boilers on free-standing frames for in-line and back-to-back configurations.

Installation Area and Dimensions Guide

Provides guidance on required clearances for installation, servicing, and flue system installation.

4 WALL MOUNTED INSTALLATION

Wall Mounted Side By Side Option

Step-by-step instructions for wall mounting boilers side-by-side, including template use and plate fixing.

5 FRAME KIT INSTALLATION

Side By Side Frame Kit Mounting Procedure

Details the procedure for assembling and securing side-by-side frame kits, including floor bolting.

Boiler Mounting on Frames or Plates

Instructions for mounting boilers onto wall plates or side-by-side frame kits.

6 HEADER KIT ASSEMBLY & CONNECTIONS

Fitting Mixing Header and Blanking Flanges

Describes fitting the mixing header and blanking flanges in chosen positions on the header assembly.

Header Kit Assembly Procedure

Step-by-step guide for assembling the header kit to the frame legs and connecting components.

Gas Connection Fitting

Procedure for connecting the gas supply to the boiler and header assembly.

Pressure Relief Valve Connection Safety

Ensures each boiler's pressure relief connection is piped safely.

Condensate Siphon Fitting

Details the fitting of the condensate siphon to the boiler and piping to the drain.

7 INSTALLATION DRAWINGS

7.1 General System Formats

Outlines the three available formats for multiple boiler systems: wall-mounted and free-standing frame configurations.

7.2 Side By Side Frame Kit Configurations

Presents installation drawings for side-by-side frame kit configurations with various boiler numbers and types.

7.3 Back To Back Frame Kit Configurations

Presents installation drawings for back-to-back frame kit configurations with various boiler numbers and types.

8 ELECTRICAL CONNECTIONS & WIRING

Boiler Pump Speed Control & Wiring Diagram

Provides the electrical connections and wiring diagram for boiler pump speed control and external controls.

9 COMMISSIONING AND TESTING

Electrical and Gas Safety Checks

Emphasizes the need for electrical and gas safety checks after installation, similar to individual boiler commissioning.

Pump Setting Guide

Guides users on setting the pump types (UPML/UPMXXL) for optimal performance in different configurations.

Need help?

Do you have a question about the Evomax 2 150 and is the answer not in the manual?

Questions and answers