Table of Contents

Advertisement

ORIGINAL INSTRUCTIONS

Installation, Operation

& Maintenance Manual

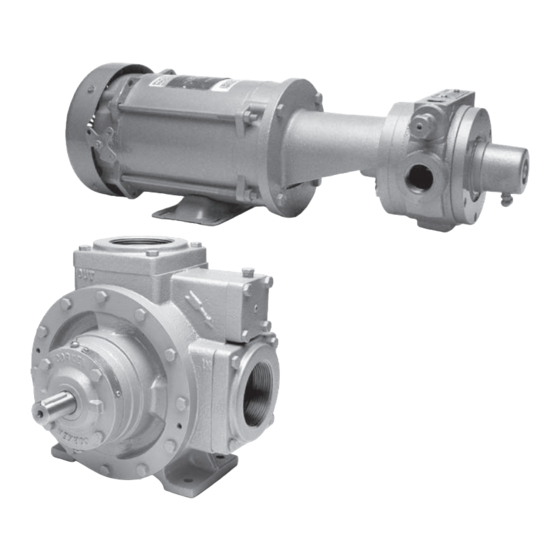

Sliding-Vane Stationary Pumps for LPG and NH

All Models 51, 521, and 1021

1021 Model

Warning: (1) Periodic inspection and maintenance of Corken products is essential. (2) Inspection, maintenance and installation of Corken

products must be made only by experienced, trained and qualified personnel. (3) Maintenance, use and installation of Corken products

must comply with Corken instructions, applicable laws and safety standards (such as NFPA Pamphlet 58 for LP-Gas and ANSI K61.1-1972

for Anhydrous Ammonia). (4) Transfer of toxic, dangerous, flammable or explosive substances using Corken products is at user's risk and

equipment should be operated only by qualified personnel according to applicable laws and safety standards.

Solutions beyond products...

D51 Model

IC101H

3

Advertisement

Table of Contents

Summarization of Contents

Installation Procedures

Pump Location Guidelines

Proper placement for optimal pump performance, considering tank proximity and elevation.

Inlet Piping Requirements

Specifies minimum sizes, connections, and strainer types for pump inlet piping.

Outlet Piping Requirements

Details requirements for pressure gauges, relief valves, and check valves in outlet piping.

Bypass System Requirements

Mandates installation of an external bypass valve for pump protection against over-pressure.

Vapor Equalizing System Benefits

Explains how a vapor line improves system performance by balancing tank pressures.

Driver Installation Guidelines

Covers electrical wiring and motor connection considerations for proper driver installation.

Operation Procedures

Initial Pumping Operation Steps

Step-by-step guide for the first startup and operation of the pump.

Maintenance Procedures

Bleed Down Safety Precautions

Critical safety measures to prevent hazards during system bleed-down processes.

Preventative Maintenance Schedule

Outlines routine checks and inspections for optimal pump longevity and safety.

Seal Replacement Instructions

Seal Installation Steps

Detailed guide on depessurizing, removing old seals, and installing new ones.

Cleanliness and Workmanship

Emphasizes proper handling and installation of seals for reliable performance.

Repair Kits and Spare Parts

Lists available repair kits and individual spare parts for pump maintenance.

Appendix A: Model Number Identification Code

Models D51 and F51 Identification

Explains the coding system for identifying D51 and F51 pump models and their options.

Models 521, 1021, F1021 Identification

Details the model number structure for 521, 1021, and F1021 pumps, including options.

Appendix B: Specifications

D51 and F51 Specifications

Provides operating and material specifications for D51 and F51 pump models.

521, 1021, F1021 Specifications

Lists operating parameters and material details for 521, 1021, and F1021 pump models.

Appendix C: Performance Curves

D51 and F51 Performance Curves

Graphs showing capacity and power (bhp) versus differential pressure for D51/F51.

Model 521 Performance Curves

Performance data graphs for Model 521 at various RPMs.

Model 1021 Performance Curves

Performance data graphs for Model 1021 at various RPMs.

Appendix D: Outline Dimensions

D51 and F51 Outline Dimensions

Drawings with measurements for D51 and F51 pump models.

Model F51-101 Outline Dimensions

Drawings with measurements for the F51-101 frame mount pump.

Models 521 and 1021 Outline Dimensions

Drawings with measurements for 521 and 1021 pump models.

Model F1021 Outline Dimensions

Drawings with measurements for the F1021 pump model.

Models 521 and 1021-103 Outline Dimensions

Drawings with measurements for 521 and 1021-103 pump models.

Model F1021-103 Outline Dimensions

Drawings with measurements for the F1021-103 pump model.

Appendix E: Parts Details

Seal Assembly Parts (2296 Series)

Detailed breakdown of parts for the 2296 series seal assembly.

Model D51 Parts Details

Illustrated parts breakdown for the D51 direct mount pump.

Model F51 Parts Details

Illustrated parts breakdown for the F51 frame mount pump.

Seal Assembly Parts (1769 Series)

Detailed breakdown of parts for the 1769 series seal assembly.

Models 521 and 1021 Parts Details

Illustrated parts breakdown for 521 and 1021 pump models.

Model F1021 Parts Details

Illustrated parts breakdown for the F1021 pump model.

Rotor, Blade, Sideplate, Cam Parts

Interface dimensions for key pump components like rotor, blade, sideplate, and cam.

Need help?

Do you have a question about the 1021 and is the answer not in the manual?

Questions and answers