Summarization of Contents

Health and Safety Precautions

Health and Safety Overview

General safety principles and responsibilities for users and the company.

Hazardous Substances and WEEE Compliance

Requirements for assessing substances and product compliance with WEEE directive.

Hazard Signal Words and Fail-Safe

Defines keywords like WARNING/CAUTION and explains fail-safe mechanisms.

Introduction to the Q150T System

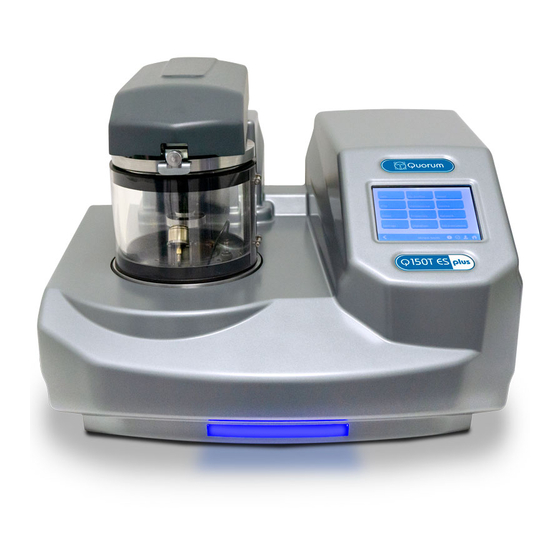

System Overview and Models

Overview of the Q150T system's capabilities, models, and basic functions.

Core Capabilities

Details on sputter coating, carbon coating, metal evaporation, and aperture cleaning.

Installation and Connections

Pre-installation and Required Services

Identifies suitable location, environmental conditions, and necessary gas/electrical supplies.

Unpacking and Initial Checks

Instructions for safely removing the instrument from packaging and checking for damage.

Connecting Gas, Power, and Vacuum

Guides for connecting gas inlets, electrical supply, pump, and vacuum hose.

Network Connection Setup

Steps to connect the instrument to a network via CAT5/5e cable.

Instrument Operation Basics

Initial Power-On and Standby Screen

How to switch on the instrument and navigate the initial standby display.

Running and Monitoring Process Profiles

Steps to select, start, and monitor pre-defined sputtering or evaporation processes.

Profile Management

Editing and Creating Process Profiles

Modifying existing profiles or creating new ones using the Profile Editor.

Managing Material Properties

Adding, editing, or deleting material definitions and their associated properties.

Application Guidelines

QT Timed and FTM Terminated Sputtering

Guidelines for SEM coatings using timed and FTM-terminated sputter processes.

Carbon Evaporation Techniques

Procedures for pulsed cord, controlled pulse cord, and pulsed rod carbon evaporation.

Metal Evaporation and Aperture Cleaning

Performing metal evaporation and using the configuration for aperture cleaning.

Ramped Profile for Carbon Coatings

Using the ramped profile for consistent carbon coatings and support layers.

Instrument Configuration and Management

Outgas Options and Glow Discharge

Configuring outgassing behavior and using glow discharge for cleaning/hydrophilisation.

Instrument Settings and Parameters

Configuring network, sputter, vacuum, maintenance, and hardware settings.

User and System Management

Managing user access levels, groups, and system overrideable parameters.

FTM, Clock, and Process Logging

Monitoring FTM status, setting date/time, and viewing process logs.

Accessories and Spares

Installing Inserts and Stages

Guides for installing sputter, carbon, metal evaporation, glow discharge inserts, and various stages.

FTM and Other Accessories

Installing the Film Thickness Monitor and other accessories like cylinders and gauges.

Spares and Replacement Parts

Lists available spare parts, consumables, and replacement targets for the Q150T.

Service, Maintenance, and Troubleshooting

Routine Maintenance Procedures

Schedule of regular maintenance tasks for the instrument and its components.

Troubleshooting and Error Messages

Guidance on diagnosing issues, understanding error messages, and warnings.

Appendices and Specifications

Profile Parameter Reference

Detailed lists of parameters for various profile types.

Technical Specifications and Deposition Rates

Key technical data, specifications, and sputtering deposition rate graphs.

Return of Goods Procedures

Information and procedures for returning equipment, including declaration forms.

Need help?

Do you have a question about the Q150T ES and is the answer not in the manual?

Questions and answers