Table of Contents

Advertisement

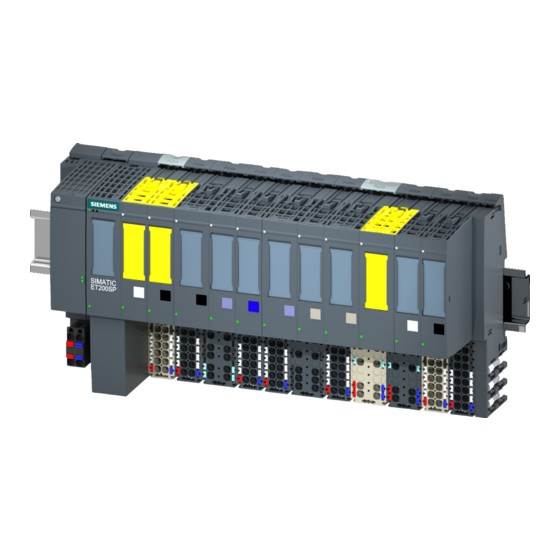

ET 200SP distributed I/O system

SIMATIC

ET 200SP

ET 200SP distributed I/O system

Product Information

Translation of original operating instructions

07/2013

A5E32288220-AA

___________________

Preface

___________________

Product overview

___________________

Application planning

___________________

Installation

___________________

Connecting

___________________

Configuring

___________________

Maintenance

___________________

Technical specifications

___________________

Accessories/spare parts

1

2

3

4

5

6

7

8

Advertisement

Table of Contents

Summarization of Contents

Preface

Scope of the product information

Details the scope and purpose of this product information document concerning fail-safe modules.

Product overview

What are fail-safe automation systems and fail-safe modules?

Explains fail-safe automation systems and the characteristics of fail-safe modules.

Achievable safety classes

Outlines the safety classes (SIL, Performance Level) achievable with fail-safe modules.

Use in SIMATIC Safety F-systems

Describes how ET 200SP fail-safe modules are utilized within SIMATIC Safety F-systems.

Application planning

Introduction

Introduces the configuration possibilities for ET 200SP with fail-safe and non-fail-safe modules.

Assembly example for ET 200SP with fail-safe and non-fail-safe modules

Provides an example configuration of mixed fail-safe and non-fail-safe modules.

Installation

Basics

Covers fundamental installation requirements for ET 200SP fail-safe modules.

Connecting

Safe functional extra-low voltage (SELV) for fail-safe modules

Specifies the requirement for safe functional extra-low voltage (SELV) for fail-safe modules.

Power supply requirements for compliance with NAMUR recommendations

Details power supply requirements adhering to NAMUR recommendations.

Requirements of sensors and actuators for fail-safe modules

Details qualifications and specifications for sensors and actuators used with fail-safe modules.

Capacitive crosstalk of digital input/output signals

Addresses potential errors caused by capacitive crosstalk and their remedies.

Configuring

Assigning the F-destination address for fail-safe modules

Explains the procedure for assigning the F-destination address to fail-safe modules.

Maintenance

Firmware update

Describes the process and requirements for updating the firmware of fail-safe modules.

Technical specifications

Protecting ET 200SP with fail-safe modules against overvoltages

Provides recommendations for protecting ET 200SP fail-safe modules from overvoltages.

Standards and approvals

Lists the EC directives and harmonized European Standards the system complies with.

Accessories/spare parts

Lightning protection and overvoltage protection for fail-safe modules

Discusses overvoltage suppressors and protection components for fail-safe modules.

Components for overvoltage protection of fail-safe modules (lightning protection zone transition 0s to 1)

Lists specific overvoltage arresters for fail-safe modules, including article numbers.

Glossary

1001 evaluation

Defines sensor evaluation where one sensor has a 1-channel connection.

1002 evaluation

Defines sensor evaluation using two input channels for comparison.

Acknowledgment time

Time for F-I/O to acknowledge the sign of life from the F-CPU.

Actuator

Devices that switch loads, like relays or solenoid valves.

Availability

Probability that a system is functional at a specific point in time.

Channel fault

Channel-specific fault, such as wire break or short circuit.

Channel group

Grouping of module channels for parameter assignment.

Channel number

Unique identifier for module inputs/outputs for diagnostics.

Channel-specific passivation

Passivation of only the affected channel in case of a channel fault.

CRC

Cyclic Redundancy Check for data validation.

CRC signature

Validates process values and parameters using a CRC check.

Dark period

Brief deactivation of output during test cycles.

Derating

Refers to temperature characteristics.

Discrepancy analysis

Analysis to prevent errors from time differences in input signals.

Discrepancy time

Configurable time for discrepancy analysis.

F-CPU

Central processing unit with fail-safe capability in SIMATIC Safety.

F-I/O

Collective name for fail-safe inputs and outputs in SIMATIC Safety.

Fail-safe modules

ET 200SP modules with integrated safety functions for safety-related operation.

Fail-safe systems

Systems that remain in or assume a safe state upon failure.

Fault response time

Interval between a fault occurrence and a safe reaction.

Fault tolerance time

Time a process can be left unattended without risk.

F-monitoring time

Monitoring time for safety-related communication.

F-Systems

Fail-safe automation systems.

Module fault

External or internal faults affecting a module.

Monitoring time

Refers to PROFIsafe monitoring time.

M-switch

Part of fail-safe digital output for current sinking.

Nonequivalent sensor

Sensor connected via 2 channels for fail-safe systems.

Passivation

Switching channels to a safe state due to detected faults.

Performance Level

Safety rating according to ISO 13849-1.

PROFIsafe

Safety-oriented PROFINET I/O bus profile.

PROFIsafe address

Address configured for each fail-safe module.

PROFIsafe monitoring time

Monitoring time for safety-related communication between F-CPU and F-I/O.

Proof-test interval

Period after which a component must be forced to fail-safe state.

P-switch

Part of fail-safe digital output for current sourcing.

Redundancy, availability-enhancing

Use of multiple components to maintain functionality during faults.

Redundancy, safety-enhancing

Multiple component availability for exposing hardware faults.

Reintegration

Process of switching from fail-safe to process values after fault elimination.

Safe state

The basic principle of the safety concept in F-systems.

Safety class

Safety Integrity Level (SIL) according to IEC 61508.

Safety function

Mechanism enabling fail-safe operation within SIMATIC Safety.

Safety message frame

Frame used for transferring data in safety mode.

Safety mode

Operating mode for safety-related communication.

Safety program

Safety-related user program.

Safety-related communication

Communication for exchanging fail-safe data.

Sensor evaluation

Methods for reading and comparing sensor signals.

Sensors

Devices for accurate detection of digital and analog signals.

SIL

Safety Integrated Level, synonymous with safety class.

Standard mode

Operating mode for standard communication, not safety-related.

Value status

Binary information on the validity of a digital signal.

Need help?

Do you have a question about the ET 200SP distributed I/O system and is the answer not in the manual?

Questions and answers