Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Summarization of Contents

1 Safety

1.1 Important provisions for all products

Key guidelines for safe operation and maintenance of all products.

1.2 Personnel and organizational requirements

Specifies requirements for personnel and operator organization for safe work.

1.3 Transport

Instructions and safety precautions for transporting the engine.

1.4 Safety regulations for maintenance and repair work

Safety rules to follow before, during, and after maintenance and repair.

1.5 Fire prevention and environmental protection, fluids and lubricants, auxiliary materials

Guidelines for fire safety, environmental care, and handling of fluids/materials.

1.6 Standards for safety notices in the text

Explains the meaning of different safety notice symbols used in the manual.

2 Product Summary

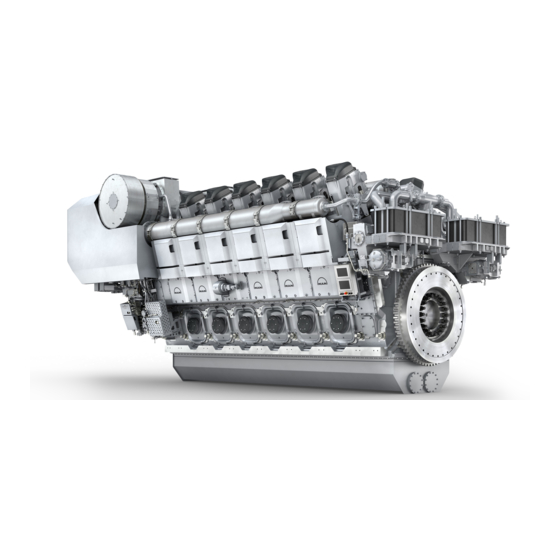

2.1 Engine Layout

Provides an overview of the engine's physical arrangement and components.

2.2 Engine Side and Cylinder Designations

Defines how engine sides and cylinders are identified and numbered.

2.3 Main Engine Dimensions

Lists the primary physical dimensions (length, width, height) of the engine.

2.4 Firing Sequence

Details the sequence in which cylinders fire for 12V and 16V engines.

2.5 Technical Data

Presents detailed technical specifications and operating parameters for the engine.

3 Operation

3.1 Controls

Describes the various controls for operating the engine and its systems.

3.2 Putting the engine into operation after extended out-of-service periods (>3 months)

Step-by-step guide for recommissioning the engine after long periods of inactivity.

3.3 Putting the engine into operation after scheduled out-of-service-period

Procedures for bringing the engine back online after planned downtime.

3.4 Starting the engine

Instructions on how to start the engine using the automation system.

3.5 Operational checks

Lists essential checks to perform during engine operation for safety and performance.

3.6 Tasks after extended out-of-service periods (>3 weeks)

Specific tasks required after the engine has been out of service for more than three weeks.

3.7 Checks prior to start-up

Pre-start checks to ensure the engine and its systems are ready for operation.

3.8 Fuel treatment system – Putting into operation

Steps to put the fuel treatment system into operational status.

3.9 Fuel treatment system – Switching on

Procedure for turning on the fuel treatment system.

3.10 Fuel treatment system – Shutdown

Steps for safely shutting down the fuel treatment system.

3.11 Stopping the engine

Guidance on the correct procedure for stopping the engine.

3.12 Emergency engine stop

Procedures and warnings related to the emergency engine stop function.

3.13 After stopping the engine

Actions to take after the engine has been stopped, especially for extended periods.

3.14 Plant – Cleaning

Instructions for cleaning the plant equipment, including safety precautions.

4 Maintenance

4.1 Maintenance task reference table [QL1]

A table cross-referencing maintenance tasks with their respective procedures and page numbers.

5 Troubleshooting

5.1 Troubleshooting

General guidance and common issues encountered during engine operation.

5.2 Fuel treatment system – Troubleshooting

Specific troubleshooting steps for the fuel treatment system.

5.3 Engine governor ADEC (ECU 7) fault messages for Series 4000 engines, marine application

Lists and explains fault messages from the ADEC engine governor.

5.4 ADEC engine governor – Fault codes

Detailed fault codes for the ADEC engine governor and their corrective actions.

6 Task Description

6.1 Engine

Describes tasks related to the engine itself.

6.1.1 Engine – Barring manually

Step-by-step instructions for manually barring the engine.

6.2 Cylinder Liner

Information and procedures related to cylinder liners.

6.2.1 Cylinder liner – Endoscopic examination

Procedure for inspecting cylinder liners using an endoscope.

6.3 Valve Drive

Tasks and information related to the engine's valve drive system.

6.3.1 Valve gear – Lubrication

Instructions for lubricating the valve gear components.

6.3.2 Valve clearance – Check and adjustment

Procedure for checking and adjusting valve clearances.

6.3.3 Cylinder head cover – Removal and installation

Steps for removing and installing the cylinder head cover.

6.4 Injection Pump / HP Pump

Tasks related to the high-pressure injection pump.

6.4.1 HP pump – Filling with engine oil

Procedure for filling the HP pump with engine oil.

6.4.2 HP pump – Relief bore check

How to check the relief bore of the HP pump for discharge.

6.5 Injection Valve / Injector

Procedures for working with injection valves and injectors.

6.5.1 Injector – Replacement

Steps for replacing an injector.

6.5.2 Injector – Removal and installation

Detailed procedure for removing and installing injectors.

6.6 Fuel Filter

Information and tasks related to the fuel filter system.

6.6.1 Supplementary fuel filter – Overview

Explains the components of the supplementary fuel filter system.

6.6.2 Additional fuel filter – Replacement

Procedure for replacing the additional fuel filter.

6.6.3 Fuel filter – Replacement

Steps for replacing the main fuel filter.

6.6.4 Fuel prefilter – Differential pressure check and adjustment of gauge

How to check and adjust the differential pressure gauge for the fuel prefilter.

6.6.5 Fuel prefilter – Draining

Instructions for draining the fuel prefilter.

6.6.6 Fuel prefilter – Flushing

Procedure for flushing the fuel prefilter.

6.6.7 Fuel prefilter with water separator – Filter element replacement

Steps for replacing the filter element in the fuel prefilter with water separator.

6.6.8 Fuel prefilter with water separator – O-ring replacement in rotary slide valve

Procedure for replacing the O-ring in the rotary slide valve of the fuel prefilter.

6.7 Exhaust Turbocharger

Tasks related to the exhaust turbocharger.

6.7.1 Compressor wheel – Cleaning

Instructions for cleaning the turbocharger's compressor wheel.

6.8 Charge-Air Cooling

Information about the charge-air cooling system.

6.8.1 Charge-air cooler – Checking condensate drain for water discharge and obstruction

How to check the charge-air cooler's condensate drain.

6.9 Air Filter

Tasks related to the air filter.

6.9.1 Air filter – Replacement

Procedure for replacing the air filter.

6.9.2 Air filter – Removal and installation

Steps for removing and installing the air filter.

6.10 Air Intake

Information about the air intake system.

6.10.1 Service indicator – Signal ring position check (optional)

How to check the signal ring position of the service indicator.

6.11 Starting Equipment

Tasks related to the engine's starting equipment.

6.11.1 Starter – Condition check

Procedure for checking the condition of the starter.

6.12 Lube Oil System, Lube Oil Circuit

Information about the engine's lube oil system and circuit.

6.12.1 Engine oil – Level check

How to check the engine oil level.

6.12.2 Engine oil – Change

Procedure for changing the engine oil.

6.12.3 Engine oil – Sample extraction and analysis

Steps for extracting and analyzing engine oil samples.

6.13 Oil Filtration / Cooling

Tasks related to oil filtration and cooling systems.

6.13.1 Checking oil indicator filter

Procedure for checking the oil indicator filter.

6.13.2 Engine oil filter – Replacement

Steps for replacing the engine oil filter.

6.13.3 Centrifugal oil filter – Cleaning and filter sleeve replacement

How to clean the centrifugal oil filter and replace its sleeve.

6.14 Coolant Circuit, General, High-Temperature Circuit

Information about the engine coolant circuit.

6.14.1 Drain and vent points

Identifies points for draining and venting the coolant system.

6.14.2 Engine coolant level – Check

How to check the engine coolant level.

6.14.3 Engine coolant – Change

Procedure for changing the engine coolant.

6.14.4 Engine coolant – Draining

Instructions for draining the engine coolant.

6.14.5 Engine coolant – Filling

Procedure for filling the engine coolant system.

6.14.6 HT coolant pump – Relief bore check

How to check the relief bore of the HT coolant pump.

6.14.7 Engine coolant – Sample extraction and analysis

Steps for extracting and analyzing engine coolant samples.

6.14.8 Engine coolant filter – Replacement

Procedure for replacing the engine coolant filter.

6.14.9 Preheating unit

Information about the engine preheating unit.

6.15 Raw Water Pump with Connections

Tasks related to the raw water pump and its connections.

6.15.1 Raw water pump – Relief bore check

How to check the relief bore of the raw water pump.

6.16 Battery-Charging Generator

Information about the battery-charging generator.

6.16.1 Battery-charging generator drive – Coupling condition check

How to check the coupling condition of the battery-charging generator drive.

6.17 Auxiliary PTO

Information about the auxiliary PTO.

6.17.1 Bilge pump – Relief bore check

How to check the relief bore of the bilge pump.

6.18 Engine Mounting / Support

Tasks related to engine mounting and support.

6.18.1 Engine mounting – Check

Procedure for checking the engine mounting.

6.19 Fuel Supply System

Information about the fuel supply system.

6.19.1 Water drain valve – Check

How to check the water drain valve.

6.19.2 Differential pressure gauge – Check

Procedure for checking the differential pressure gauge.

6.19.3 Water level probe (3-in-1 rod electrode) – Check

How to check the water level probe.

6.19.4 Pump capacity – Check

Procedure for checking the pump capacity.

6.19.5 Coalescer filter element – Replacement

Steps for replacing the coalescer filter element.

6.20 Wiring (General) for Engine/Gearbox/Unit

General wiring information for the engine and related units.

6.20.1 Overview of engine wiring harness

Provides an overview of the engine wiring harness and terminal assignments.

6.20.2 Engine wiring – Check

Procedure for checking the engine wiring.

6.21 Accessories for (Electronic) Engine Governor / Control System

Information about accessories for the engine governor and control system.

6.21.1 Limit switch for start interlock ‒ Check

How to check the limit switch for start interlock.

6.21.2 Engine Control Unit ECU 7 – Checking plug connections

Procedure for checking the plug connections on the ECU 7.

6.21.3 Engine monitoring unit EMU – Plug connection check

How to check the plug connections for the EMU.

6.21.4 Interface module EIM plug connections – Check

Procedure for checking the plug connections on the EIM.

6.21.5 Engine Control Unit ECU 7 – Removal and installation

Steps for removing and installing the ECU 7.

6.21.6 EMU 7 – Removal and installation

Procedure for removing and installing the EMU 7.

6.21.7 Diagnostic features of EIM

Explains the diagnostic features of the EIM, including lamps and signals.

6.21.8 Engine Interface Module EIM – Removal and installation

Procedure for removing and installing the EIM.

6.21.9 CDC parameters – Reset

Instructions for resetting CDC parameters.

7 Appendix A

7.1 Abbreviations

Lists and defines abbreviations used throughout the manual.

7.2 MTU contact persons/service partners

Provides contact information for MTU support and service partners.

8 Appendix B

8.1 Special Tools

Lists special tools required for various tasks, with part numbers and usage.

8.2 Index

An alphabetical index to locate specific topics within the manual.

Need help?

Do you have a question about the 16 V 4000 M53 and is the answer not in the manual?

Questions and answers