Bosch Professional GOP 12V-28 Manual

- Original instructions manual (301 pages) ,

- Instructions manual (301 pages) ,

- Operating/safety instructions manual (65 pages)

Advertisement

Safety instructions

General Power Tool Safety Warnings

Read all safety warnings, instructions, illustrations and specifications provided with this power tool. Failure to follow all instructions listed below may result in electric shock, fire and/ or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mainsoperated (corded) power tool or battery-operated (cordless) power tool.

Work area safety

- Keep work area clean and well lit. Cluttered or dark areas invite accidents.

- Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

- Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

Electrical safety

Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock.

Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

If operating a power tool in a damp location is unavoidable, use a residual current device (RCD) protected supply. Use of an RCD reduces the risk of electric shock.

Personal safety

- Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools may result in serious personal injury.

- Use personal protective equipment. Always wear eye protection. Protective equipment such as a dust mask, non-skid safety shoes, hard hat or hearing protection used for appropriate conditions will reduce personal injuries.

- Prevent unintentional starting. Ensure the switch is in the off-position before connecting to power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger on the switch or energising power tools that have the switch on invites accidents.

- Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool may result in personal injury.

- Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

- Dress properly. Do not wear loose clothing or jewellery. Keep your hair and clothing away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

- If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of dust collection can reduce dust-related hazards.

- Do not let familiarity gained from frequent use of tools allow you to become complacent and ignore tool safety principles. A careless action can cause severe injury within a fraction of a second.

Power tool use and care

- Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

- Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

- Disconnect the plug from the power source and/or remove the battery pack, if detachable, from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

- Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

- Maintain power tools and accessories. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the power tool's operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

- Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

- Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended could result in a hazardous situation.

- Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery handles and grasping surfaces do not allow for safe handling and control of the tool in unexpected situations.

Battery tool use and care

Recharge only with the charger specified by the manufacturer. A charger that is suitable for one type of battery pack may create a risk of fire when used with another battery pack.

Use power tools only with specifically designated battery packs. Use of any other battery packs may create a risk of injury and fire.

When battery pack is not in use, keep it away from other metal objects, like paper clips, coins, keys, nails, screws or other small metal objects, that can make a connection from one terminal to another. Shorting the battery terminals together may cause burns or a fire.

Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help. Liquid ejected from the battery may cause irritation or burns.Do not use a battery pack or tool that is damaged or modified. Damaged or modified batteries may exhibit unpredictable behaviour resulting in fire, explosion or risk of injury.

- Do not expose a battery pack or tool to fire or excessive temperature. Exposure to fire or temperature above 130°C may cause explosion.

Follow all charging instructions and do not charge the battery pack or tool outside the temperature range specified in the instructions. Charging improperly or at temperatures outside the specified range may damage the battery and increase the risk of fire.

Service

- Have your power tool serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the power tool is maintained.

- Never service damaged battery packs. Service of battery packs should only be performed by the manufacturer or authorized service providers.

Safety information for the product

Hold power tool by insulated gripping surfaces, when performing an operation where the cutting accessory may contact hidden wiring. Cutting accessory contacting a "live" wire may make exposed metal parts of the power tool "live" and could give the operator an electric shock.

Only use the power tool for dry sanding. Water entering a power tool will increase the risk of electric shock.

Danger of fire! Avoid overheating the workpiece and the sander. Always empty the dust collector before taking a break from work. Sanding dust in the dust bag, microfilter, paper bag (or in the filter bag or vacuum cleaner filter) can spontaneously combust under certain conditions, for example if flying sparks are created when sanding metals. This risk is increased if the sanding dust is mixed with paint or polyurethane residue or with other chemical substances and if the workpiece is hot as a result of prolonged work.- Keep hands away from the sawing area. Do not reach under the workpiece. Contact with the saw blade can lead to injuries.

- Clean the air vents on your power tool regularly. The motor's fan will draw the dust inside the housing and excessive accumulation of powdered metal may cause electrical hazards.

Use suitable detectors to determine if there are hidden supply lines or contact the local utility company for assistance. Contact with electric cables can cause fire and electric shock. Damaging gas lines can lead to explosion. Breaking water pipes causes property damage.- Hold the power tool firmly with both hands and make sure you have a stable footing. The power tool can be more securely guided with both hands.

- When changing the application tool, wear protective gloves. Application tools can become hot when used for prolonged periods of time.

Do not scrape any dampened materials (e.g. wallpaper) or on damp surfaces. Water entering a power tool increases the risk of electric shock.

- Do not treat the surface you will be working on with any fluids that contain solvents. Poisonous vapours may develop due to the materials heating up when being scraped.

- Take particular care when handling scrapers and blades. The application tools are very sharp. Danger of injury.

- Secure the workpiece. A workpiece clamped with clamping devices or in a vice is held more secure than by hand.

- In case of damage and improper use of the battery, vapours may be emitted. Ensure the area is well-ventilated and seek medical attention should you experience any adverse effects. The vapours may irritate the respiratory system.

- Do not open the battery. There is a risk of short-circuiting.

- The battery can be damaged by pointed objects such as nails or screwdrivers or by force applied externally. An internal short circuit may occur, causing the battery to burn, smoke, explode or overheat.

- Only use the battery with products from the manufacturer. This is the only way in which you can protect the battery against dangerous overload.

Protect the battery against heat, e.g. against continuous intense sunlight, fire, water, and moisture. There is a risk of explosion.

Product description and specifications

Read all the safety and general instructions. Failure to observe the safety and general instructions may result in electric shock, fire and/or serious injury.

Please observe the illustrations at the beginning of this operating manual.

Intended use

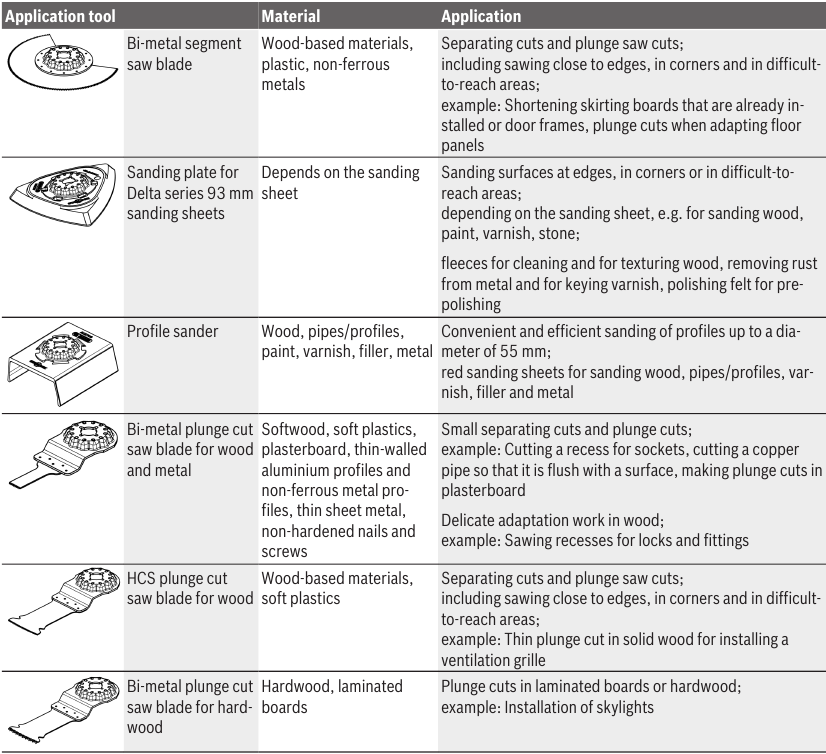

The power tool is intended for sawing and cutting woodbased materials, plastic, plasterboard, non-ferrous metals and mounting elements (e.g. non-hardened nails, clamps). It is also suitable for working on soft wall tiles and for dry sanding and scraping of small areas. It is ideal for working close to edges and flush with surfaces. The power tool must only be operated using Bosch accessories.

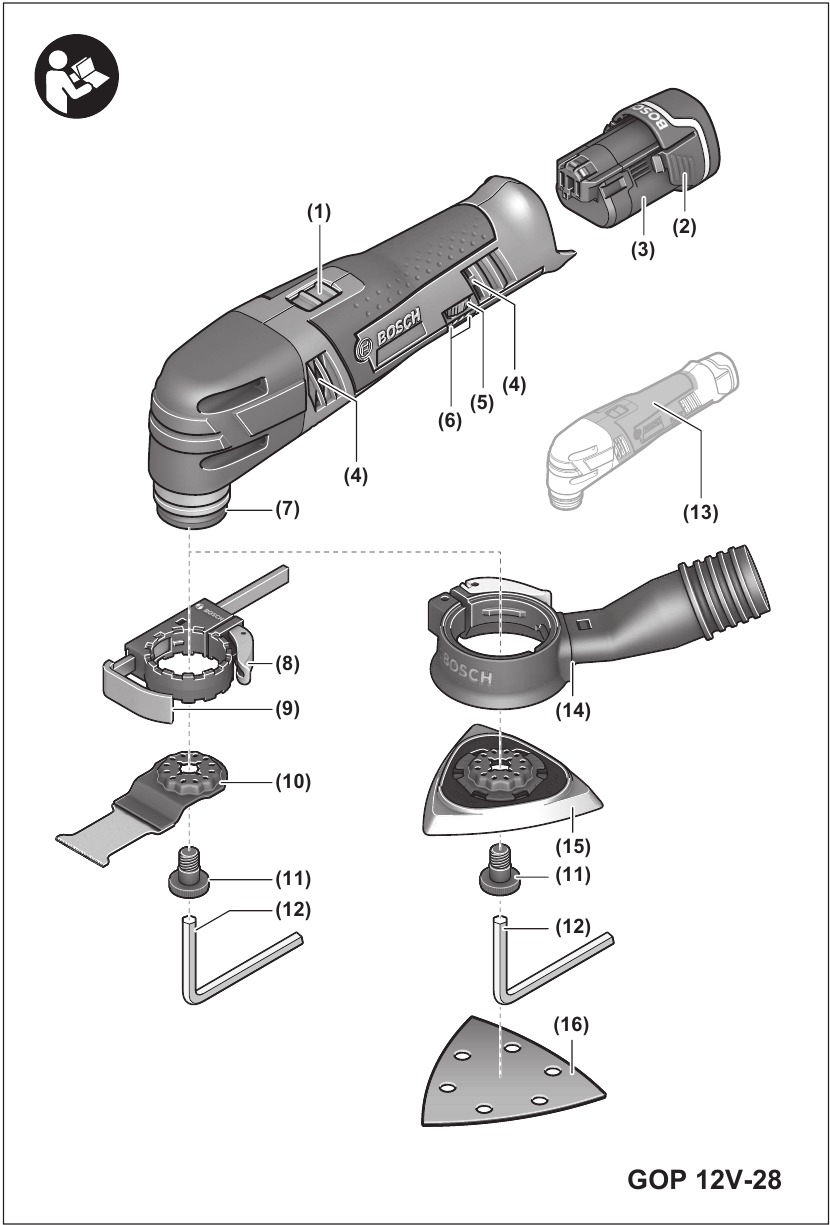

Product features

- On/off switch

- Battery release button

- BatteryA)

- Ventilation slots

- Orbital stroke rate preselection thumbwheel

- Battery charge indicator

- Tool holder

- Clamping lever of the depth stop

- Depth stop

- Plunge cut saw bladeA)

- Clamping bolt

- Hex key

- Handle (insulated gripping surface)

- Dust extraction systemA)

- Sanding plateA)

- Sanding sheetA)

- Clamping lever for dust extraction systemA)

- Dust extraction outletA)

- Dust extraction adapterA)

- Dust extraction hoseA)

A) Accessories shown or described are not included with the product as standard. You can find the complete selection of accessories in our accessories range.

Technical data

| Cordless multi-cutter | GOP 12V-28 | |

| Article number | 3 601 HB5 0.. | |

| Rated voltage | V= | 12 |

| No-load speed n0 | rpm | 5000–20000 |

| Oscillation angle on left/right | ° | 1.4 |

| Weight according to EPTA Procedure 01:2014 | kg | 0.97–1.2A) |

| Permitted ambient temperature | ||

| °C | 0 to +45 |

| °C | −20 to +50 |

| Recommended batteries | GBA 10,8V... GBA 12V... GBA 12V...W | |

| Recommended chargers | GAL 11.. CV GAL 12.. CV GAL 18...W | |

A) Depends on battery in use

B) Limited performance at temperatures <0°C

Technical data determined using the battery that comes with the product.

Fitting

- Remove the battery from the power tool before carrying out work on the power tool (e.g. maintenance, changing tool, etc.). The battery should also be removed for transport and storage. There is risk of injury from unintentionally pressing the on/off switch.

Charging the battery

- Use only the chargers listed in the technical data. Only these chargers are matched to the lithium-ion battery of your power tool.

Note: The battery is supplied partially charged. To ensure full battery capacity, fully charge the battery in the charger before using your power tool for the first time. The lithium-ion battery can be charged at any time without reducing its service life. Interrupting the charging process does not damage the battery.

The lithium-ion battery is protected against deep discharge by the "Electronic Cell Protection (ECP)". When the battery is discharged, the power tool is switched off by means of a protective circuit: The application tool no longer rotates.

To remove the battery (3), press the release buttons (2) and pull the battery back and out of the power tool. Do not use force to do this.

Follow the instructions on correct disposal.

Battery charge indicator

The three green LEDs on the battery charge indicator (6) indicate the state of charge of the battery (3). The battery charge indicator only lights up for five seconds after startup.

| LED | Capacity |

| Continuous lighting 3 x green | ≥ 2/3 |

| Continuous lighting 2 x green | ≥ 1/3 |

| Continuous lighting 1 x green | < 1/3 |

| Flashing light 1 x green | Reserve |

| Flashing light 3 x green | Empty |

If no LED lights up after switching the power tool on, then the battery is defective and must be replaced.

Changing the tool

- Wear protective gloves when changing tools. There is a risk of injury when touching the application tools.

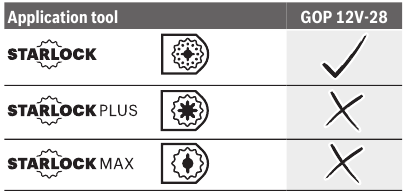

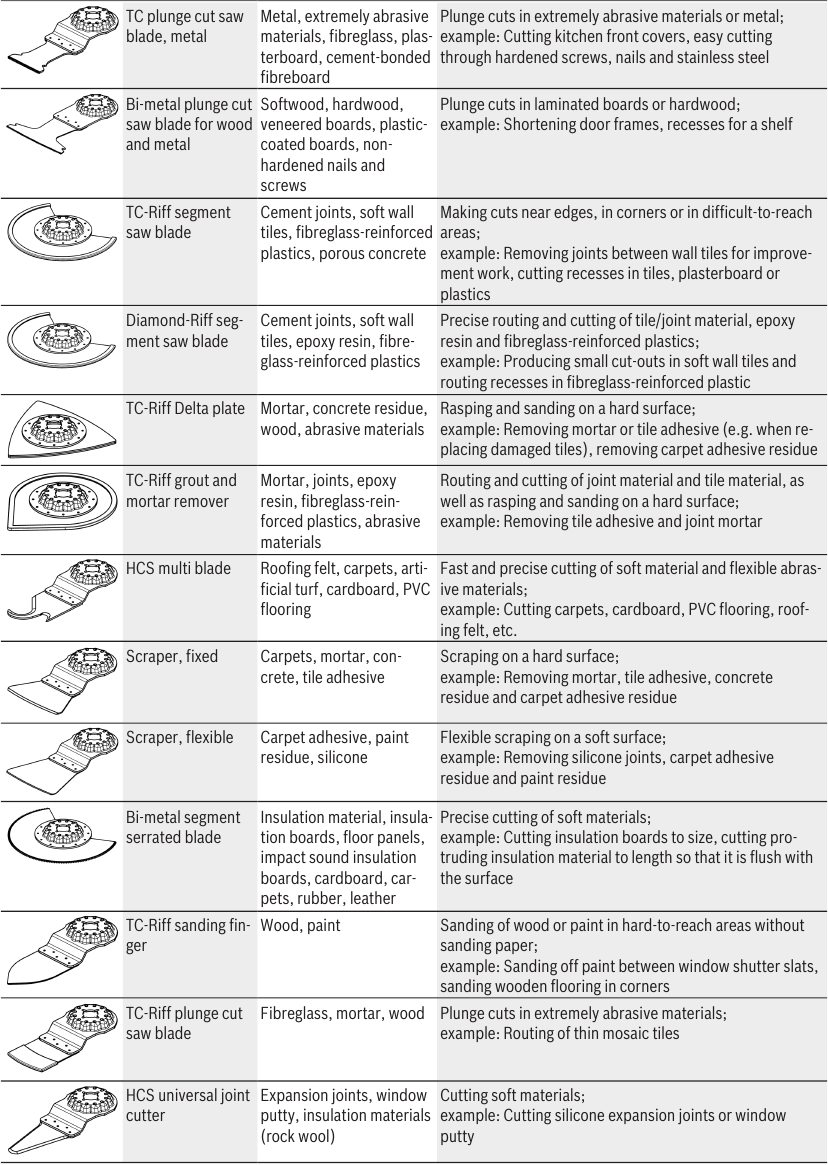

Selecting an application tool

Please observe the application tools intended for your power tool.

The following table shows examples of application tools. You can find additional application tools in Bosch's extensive range of accessories.

Fitting/changing the application tool

Remove the application tool if one has already been fitted.

To remove the application tool, use the hex key (12) to loosen the clamping bolt (11) and remove the tool.

Position the required application tool (e.g. plunge cut saw blade (10)) on the tool holder (7) so that the depressed centre is facing downwards (see figure in "Product features", text on the application tool should be legible from above).

Turn the application tool to a position which is convenient for the job at hand and allow it to lock into place in the cams of the tool holder (7). Twelve positions offset by 30° are possible for this.

Secure the application tool using the bolt (11). Tighten the bolt using the hex key (12) until the rounded head of the bolt is lying flat against the application tool.

- Check that the application tool is seated securely. Application tools that are attached incorrectly or are not securely fixed in place may come loose during operation, thereby putting you at risk.

Selecting a sanding sheet

Different sanding sheets are available, depending on the material you are working with and the required surface removal rate:

| Sanding sheet | Material | Application | Grit | |

|

| For pre-sanding, e.g. of rough and uneven beams and boards | Coarse | 40 60 |

| For surface sanding and levelling of slight irregularities | Medium | 80 100 120 | ||

| For finish-sanding and fine sanding of wood | Fine | 180 240 320 400 | ||

|

| For sanding down paint | Coarse | 40 60 |

| For sanding undercoats (e.g. removing brushstrokes, paint drips and paint runs) | Medium | 80 100 120 | ||

| For final sanding of primers prior to painting | Fine | 180 240 320 400 |

Attaching/changing the sanding sheet on the sanding plate

The sanding plate (15) is fitted with a hook-and-loop fastening, allowing sanding sheets with a hook-and-loop backing to be secured quickly and easily.

Tap the hook-and-loop fastening of the sanding plate (15) before fitting the sanding sheet (16) to facilitate maximum adhesion.

Position the sanding sheet (16) so that it is flush with one side of the sanding plate (15), then place the sanding sheet on the sanding plate and press it on firmly.

To ensure optimum dust extraction, make sure that the punched holes in the sanding sheet are aligned with the drilled holes in the sanding plate.

To remove the sanding sheet (16), take hold of it by a corner and pull it away from the sanding plate (15).

You can use all sanding sheets, polishing and cleaning fleeces from the Delta 93 mm series in Bosch's range of accessories.

Sanding accessories such as fleece/polishing felt are attached to the sanding plate in the same way.

Dust/chip extraction

The dust from materials such as lead paint, some types of wood, minerals and metal can be harmful to human health.

Touching or breathing in this dust can trigger allergic reactions and/or cause respiratory illnesses in the user or in people in the near vicinity.

Certain dusts, such as oak or beech dust, are classified as carcinogenic, especially in conjunction with wood treatment additives (chromate, wood preservative). Materials containing asbestos may only be machined by specialists.

- Use a dust extraction system that is suitable for the material wherever possible.

- Provide good ventilation at the workplace.

- It is advisable to wear a P2 filter class breathing mask.

The regulations on the material being machined that apply in the country of use must be observed.

- Avoid dust accumulation at the workplace. Dust can easily ignite.

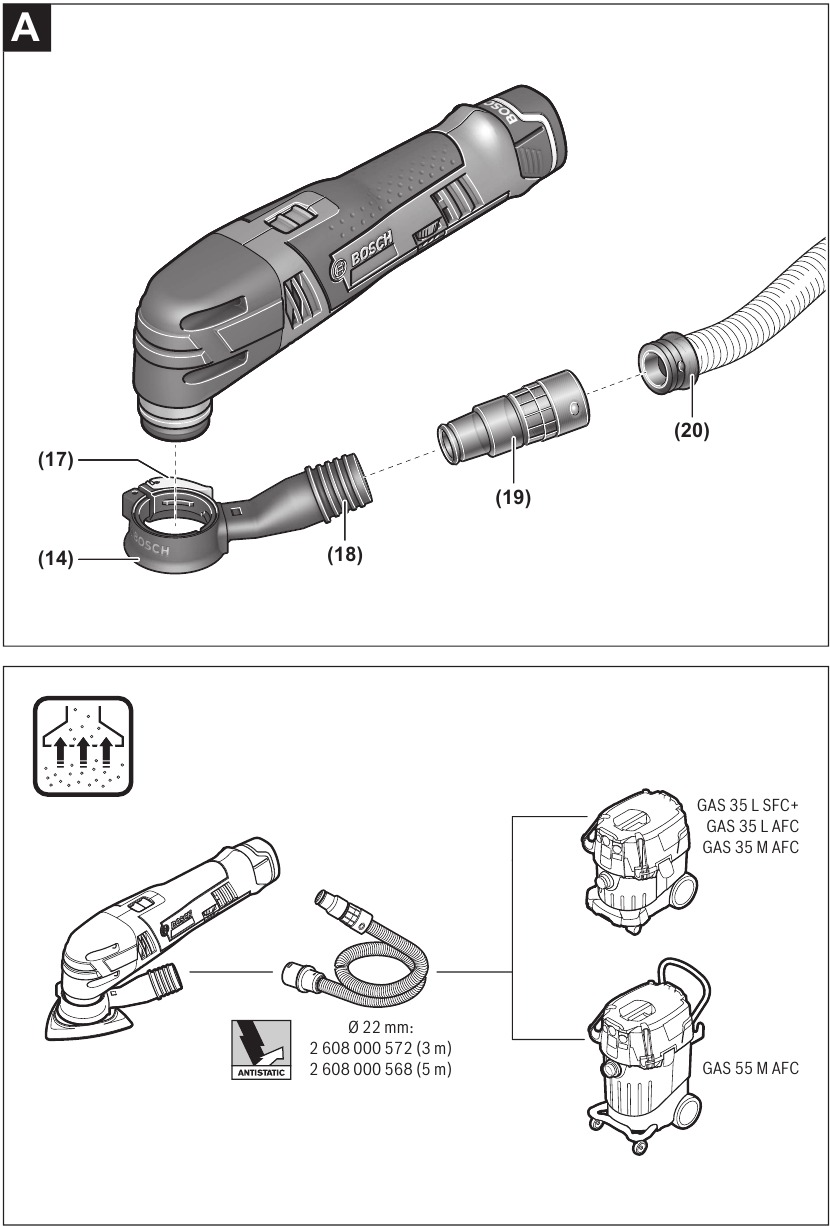

Connecting the dust extraction system (see figure A)

The dust extraction system (14) is only designed for use with the sanding plate (15); it serves no purpose when used together with other application tools.

Always connect a dust extraction system for sanding.

Remove the application tool for fitting the dust extraction system (14) (accessory).

Slide the dust extraction system (14) as far as it will go over the tool holder (7) onto the collar of the power tool. Turn the dust extraction system to the required position (not directly under the power tool). Push the clamping lever (17) shut to fix the dust extraction system in position.

Attach the dust extraction adapter (19) of the dust extraction hose (20) to the dust extraction outlet (18). Connect the dust extraction hose (20) to a dust extractor (accessory).

See an overview of connecting to various dust extractors above.

The dust extractor must be suitable for the material being worked.

When extracting dry dust that is especially detrimental to health or carcinogenic, use a special dust extractor.

Operation

Starting Operation

Inserting the battery

Use only original Bosch lithium-ion batteries with the voltage stated on the type plate of your power tool.

Using other batteries can lead to injuries and pose a fire hazard.

Note: The use of batteries unsuitable for your power tool can lead to malfunctions or damage to the power tool.

Insert the charged battery (3) into the handle until you feel it engage and it is flush with the handle.

Switching on/off

- Make sure that you are able to press the On/Off switch without releasing the handle.

To switch on the power tool, slide the on/off switch (1) forward so that "I" appears on the switch.

To switch off the power tool, slide the on/off switch (1) backward so that "0" appears on the switch.

Note: If the power tool shuts down automatically because the battery is flat or overheated, switch the power tool off using the on/off switch (1).

Charge the battery or let it cool down before switching the power tool on again. Failure to do so can damage the battery.

Preselecting the orbital stroke rate

You can even preselect the required orbital stroke rate during operation using the orbital stroke rate preselection thumbwheel (5).

The required orbital stroke rate is dependent on the material and the work conditions and can be determined using practical tests.

Orbital stroke rate level "6" is recommended for sawing, cutting and sanding harder materials, such as wood or metal; orbital stroke rate level "4" is recommended for softer materials, such as plastic.

Practical Advice

- Remove the battery from the power tool before carrying out work on the power tool (e.g. maintenance, changing tool, etc.). The battery should also be removed for transport and storage. There is risk of injury from unintentionally pressing the on/off switch.

- Always wait until the power tool has come to a complete stop before placing it down.

Note: Do not keep the ventilation slots (4) on the power tool closed when working as this will reduce the service life of the power tool.

Operating principle

The oscillating drive causes the application tool to oscillate back and forth by 2.8° up to 20,000 times per minute. This enables precise work in the tightest of spaces.

Use a consistent, low contact pressure when performing work; otherwise, the performance will be impaired and the application tool may jam.

While working, move the power tool back and forth to prevent the application tool overheating and jamming.

Sawing

- Use only undamaged saw blades that are in perfect condition. Bent or dull saw blades can break, negatively influence the cut, or lead to kickback.

- When sawing lightweight materials, take into account the statutory provisions and recommendations of the material manufacturers.

- Plunge cuts may only be applied to soft materials, such as wood, gypsum board, etc.

Before using HCS saw blades to saw into wood, chipboard, building materials, etc., check these saw blades for foreign objects, such as nails, screws, etc. Remove the foreign objects as required or use bi-metal saw blades.

Cutting

Note: When cutting wall tiles, please bear in mind that the application tools are subject to high wear if used for extended periods.

Sanding

The material removal rate and sanding result are primarily determined by the choice of sanding sheet, the preselected orbital stroke rate level and the contact pressure.

Only immaculate sanding sheets achieve good sanding performance and make the power tool last longer.

Be sure to apply consistent contact pressure in order to increase the lifetime of the sanding sheets.

Excessively increasing the contact pressure will not lead to increased sanding performance, rather it will cause more severe wear of the power tool and of the sanding sheet.

To sand corners, edges and hard-to-reach areas accurately, you can also work with the tips alone or with an edge of the sanding plate.

The sanding sheet may heat up significantly when used to sand specific points rather than entire surfaces. Reduce the orbital stroke rate and contact pressure and allow the sanding sheet to cool down at regular intervals.

Do not use a sanding sheet for other materials after it has been used to work on metal.

Use only original Bosch sanding accessories.

Always connect a dust extraction system for sanding.

Scraping

Select a high orbital stroke rate level for scraping.

Work on a soft surface (e.g. wood) at a flat angle and with low contact pressure. Failure to do so may cause the scraper to cut into the surface underneath.

Temperature-dependent overload protection

In normal conditions of use, the power tool cannot be overloaded. If the power tool is overloaded or not kept within the permitted battery temperature range, the speed is reduced or the power tool switches off. At reduced speed, the power tool will run again at full speed once the permitted battery temperature is reached or the load is reduced. If it automatically shuts down, switch the power tool off, allow the battery to cool down, then switch the power tool back on.

Recommendations for Optimal Handling of the Battery

Protect the battery against moisture and water.

Only store the battery within a temperature range of −20 to 50°C. Do not leave the battery in your car in the summer, for example.

Occasionally clean the ventilation slots on the battery using a soft brush that is clean and dry.

A significantly reduced operating time after charging indicates that the battery has deteriorated and must be replaced.

Follow the instructions on correct disposal.

Maintenance and Service

Maintenance and cleaning

- Remove the battery from the power tool before carrying out work on the power tool (e.g. maintenance, changing tool, etc.). The battery should also be removed for transport and storage. There is risk of injury from unintentionally pressing the on/off switch.

- To ensure safe and efficient operation, always keep the power tool and the ventilation slots clean.

Regularly clean Riff application tools (accessories) using a wire brush.

After-sales service and advice on using products

Our after-sales service can answer questions concerning product maintenance and repair, as well as spare parts. You can find exploded drawings and information on spare parts at: www.bosch-pt.com

The Bosch product use advice team will be happy to help you with any questions about our products and their accessories.

www.powertool-portal.de, the internet portal for tradespeople and DIY enthusiasts.

In all correspondence and spare parts orders, please always include the 10‑digit article number given on the type plate of the product.

Cambodia

Robert Bosch (Cambodia) Co., Ltd

Unit 8BC, GT Tower, 08th Floor, Street 169,

Czechoslovakia Blvd, Sangkat Veal Vong

Khan 7 Makara, Phnom Penh

VAT TIN: 100 169 511

Tel.: +855 23 900 685

Tel.: +855 23 900 660

www.bosch.com.kh

People's Republic of China

China Mainland

Bosch Power Tool (China) Co. Ltd.

Bosch Service Center

567, Bin Kang Road

Bin Kang District

Hangzhou, Zhejiang Province

China 310052

Tel.: (0571) 8887 5566 / 5588

Fax: (0571) 8887 6688 x 5566# / 5588#

E-Mail: bsc.hz@cn.bosch.com

www.bosch-pt.com.cn

HK and Macau Special Administrative Regions

Robert Bosch Co. Ltd.

21st Floor, 625 King's Road

North Point, Hong Kong

Customer Service Hotline: +852 2101 0235

Fax: +852 2590 9762

E-Mail: info@hk.bosch.com

www.bosch-pt.com.hk

India

Bosch Service Center

69, Habibullah Road, (Next to PSBB School), T. Nagar

Chennai–600077

Phone: (044) 64561816

Bosch Service Center Rishyamook

85A, Panchkuin Road

New Delhi–110001

Phone: (011) 43166190

Bosch Service Center

79, Crystal Bldg., Dr. Annie Besant Road, Worli

Mumbai–400018

Documents / Resources

References

![www.bosch-pt.com]() Home | Bosch Power Tools

Home | Bosch Power Tools![www.bosch.com.kh]() ក្រុមហ៊ុន Bosch នៅក្នុងប្រទេសកម្ពុជា | ក្រុមហ៊ុន Bosch នៅក្នុងប្រទេសកម្ពុជា

ក្រុមហ៊ុន Bosch នៅក្នុងប្រទេសកម្ពុជា | ក្រុមហ៊ុន Bosch នៅក្នុងប្រទេសកម្ពុជា博世电动工具 | 博世专业

博世電動工具 | 博世專業

Download manual

Here you can download full pdf version of manual, it may contain additional safety instructions, warranty information, FCC rules, etc.

Advertisement

Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock.

Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will reduce risk of electric shock.

Need help?

Do you have a question about the Professional GOP 12V-28 and is the answer not in the manual?

Questions and answers