Summary of Contents for Power Tech Generators PT-30KSI

- Page 1 PT-30KSI Operators Manual Power Technology Southeast, Inc. 634 State Road #44 Leesburg, FL 34748-8103 ♦ (352) 365-2777 ♦ Fax (352) 787-5545 ♦ 6/2010 PT30KSI...

- Page 2 FORWARD You are now the proud owner of a Power Technology Generator powered by a Kubota engine. This engine is a product of Kubota’s quality engineering and manufacturing. The engine is made with fine materials and manufactured under the strictest quality control standards and will assure you long satisfactory service.

- Page 3 Limited Warranty on Power Tech Generators Power Technology Southeast, Inc. warrants to you, the original purchaser, that each product of our manufacture is free from defects in materials, and workmanship. That each generator will deliver its rated output as indicated on The Power Technology Nameplate, if properly installed, serviced, and operated under normal conditions in accordance with Power Technology’s instructions.

- Page 4 SECTION 1 “SAFETY” SAFE OPERATION Observe Safety Instructions Wear Safety Clothing Check Before Operating the Engine Keep Area Around the Engine Clean Safe Handling of Fuel and Lubricants Exhaust Gases and Fire Prevention Escaping Fluids Cautions Against Burns and Battery Explosion Keep Hands and Body Away From Rotating Parts Anti-Freeze and Disposal of Fluids Conducting Safety Checks and Maintenance...

- Page 5 SAFE OPERATION Cautious operation is your best insurance against an accident. Read and understand this section carefully before operating the engine. All operators, no matter how knowledgeable they may be, should read this and other related manuals before operating the engine or any equipment attached to it. It is the owner’s responsibility to instruct all operators in safe operation.

- Page 6 KEEP AREA AROUND THE ENGINE CLEAN • Be sure to stop the engine before cleaning. • Keep the engine clean and free of accumulated dirt, grease and trash. • DO NOT stop the engine without idling; Temperatures around the engine rises suddenly. Keep the engine idling for about 5 minutes before stopping.

- Page 7 ESCAPING FLUIDS • Relieve all pressure in the air, oil and cooling systems before any lines, fittings or related items are removed or disconnected. • Be alert for possible pressure release when disconnecting any device from a system that is pressurized. DO NOT check for pressure leaks with your hands.

- Page 8 ANTI-FREEZE AND DISPOSAL OF FLUIDS • Anti-freeze contains toxic chemicals. Wear rubber gloves when handling anti-freeze. In case of contact with skin, wash immediately to avoid personal injury. • DO NOT mix different types of Anti-freeze. The mixture can produce a chemical reaction resulting in the formation of harmful substances.

- Page 9 SECTION 2 “ENGINE” PRE-OPERATION CHECK Engine Break-in Period Daily Check OPERATING THE ENGINE Engine Starting Controls Check Engine After Starting Stopping the Engine ENGINE SPECIFICATIONS Kubota Model V-2203 MBG Service Parts ENGINE MAINTENANCE SERVICE SCHEDULE ENGINE OIL MAINTENANCE Checking Engine Oil Level Lubricating Oil Specifications Engine Refill Capacities Lubricating Oil Viscosity Recommendations...

- Page 10 PRE-OPERATION CHECK NGINE BREAK-IN PERIOD uring the engine break-in period, observe the following recommendations: Change the engine oil and oil filter cartridge after the first 50 hours of operation. (See “ENGINE OIL” in ENGINE MAINTENANCE SERVICE SCHEDULE). In ambient temperature above 32°F (0°C) approximately 3-5 minutes without a load is sufficient for engine warm up.

- Page 11 OPERATING THE ENGINE ENGINE STARTING CONTROLS 1) Generator Main Switch must be in the ON position. 2) Hold Start/Stop Switch for 1 second and release. 3) Glow Plugs will preheat for 8 seconds. LED flashes slowly. 4) Preheating will cease during engine cranking cycle. LED continues flashing. 5) Engine begins an 8 seconds crank cycle, After 4 seconds of cranking the PT-ECU-63 will check for an AC signal from the generator.

- Page 12 Engine Maintenance Service Schedule Min. Every enance *See Daily Every Every 100 Every 250 Every 500 1000 Remarks e Item Note 25 Hours Hours Hours Hours Hours e Oil Level oration & e Oil Or Once a Year Or Once a Year nt Level nt Leakage...

- Page 13 ENGINE COOLANT MAINTENANCE COOLANT RECOMMENDATIONS COOLANT SERVICE LIFE For optimum performance, Power Technology Coolant Type Service Life recommends a 1:1 mixture of water / glycol. Commercial Heavy-Duty NOTE: Use a mixture that will provide Coolant/Antifreeze that 3000 Service Hours protection against the lowest ambient Meets “ASTM D5345”...

- Page 14 OPERATING HOURS and SERVICE LOG THIS SERVICE LOG IS PROVIDED TO HELP YOU KEEP AN ACCUMULATIVE RECORD OF OPERATION HOURS ON YOUR GENERATOR SET AND THE DATES REQUIRED SERVICES WERE PERFORMED. ENTER TIME TO THE NEAREST HOUR. OPERATING HOURS SERVICE RECORD HRs.

- Page 15 SECTION 3 “GENERATOR END” PRINCIPLES OF OPERATION Rotating Field Assembly (Rotor) Core Assembly Field Coil Voltage Connection Electronic Voltage Regulation Exciter Field Coil Voltage Source Balance Bearing Stator Assembly “M” SERIES EXCITER TYPE GENERATOR ASEMBLY WIRING SCHEMATICS and RESISTANCE CHARTS___________________________ 120 Volt Connection “M”...

- Page 16 GENERATOR ASSEMBLY INFORMATION EXCITER TYPE GENERATOR The exciter pole pieces contain residual magnetism, which sets up lines of force across the air gap to the exciter armature. When the exciter begins to rotate a voltage is induced and current flow is initiated in the exciter armature AC windings.

- Page 19 SECTION 4 “INSTALLATION” SAFETY PRECAUTIONS Hot Piping Dangerous Fuels Explosive Battery Gases Electrocution Moving Parts High Voltage Explosion Hot Coolant Lethal Exhaust Gas Excessive Noise Electrical Shock Backfire Flash Fire Fire Hazard Marine Application Unit Starts Without Notice Loose Components GENERATOR INSTALLATION in RECREATIONAL VEHICLES Introduction Marine Application...

- Page 20 SAFTEY PRECAUTIONS A generator set can be potentially dangerous if not properly maintained and operated. The best Safe Guard against a dangerous situation is education, good judgment and common sense. For safe trouble free operation of your generator set some general precautions are listed below. Be sure to read, understand and follow these precautions.

- Page 21 7) EXPLOSION: Never connect the negative (-) battery cable to the positive (+) connection terminal of the starter solenoid, or test the battery by shorting terminals together. This could ignite fuel vapors or cause the battery to explode. To disconnect the battery remove the negative battery cable first and reconnect it last.

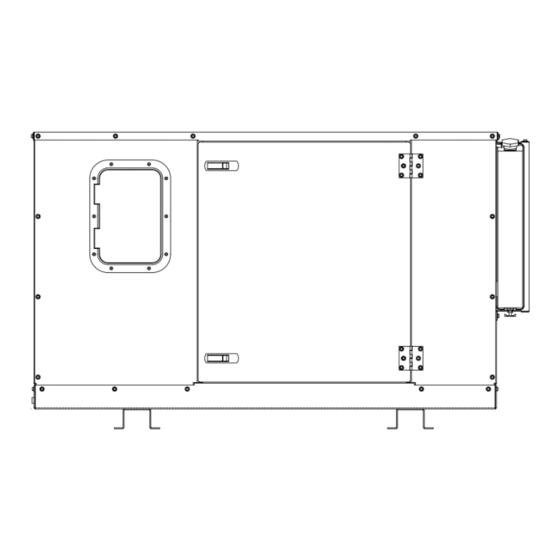

- Page 22 GENERATOR COMPARTMENT SIZE In planning the size of the generator compartment allow for the minimum clearance of (3) inches at the connection end and one (1) inch at all other sides is necessary to adequately cool the generator set. The thickness of insulation and sound deadening material used to line the compartment must be taken into consideration when planning this clearance.

- Page 24 SYSTEMS CONNECTION FUEL SYSTEM The diesel fuel system for the generator set must be designed to operate independently from the vehicles main engine if both engines are to be operated at the same time. The best way to do this is to have separate fuel tanks, but this is usually impractical because of space restrictions.

- Page 25 EXHAUST SYSTEM IMPORTANT SAFETY TIPS: When exhaust system components are not furnished by Power Technology as part of the Genset, the installer is responsible for meeting the following requirements. 1) Only use exhaust system components, which do not restrict exhaust flow. A restricted exhaust system will create excessive backpressure and may cause poor engine performance and possible engine damage.

- Page 27 ELECTRICAL CONNECTIONS ELECTRICAL WIRING All wiring must be applicable with local electrical codes. A qualified licensed electrician must perform all electrical wiring connections. Ground Fault (GFCI) breakers must be installed to protect all vehicle branch circuits. All switches and controls must be securely mounted to prevent damage and accidental opening or closing from vibration, road shock and vehicle motion.

- Page 28 MOTOR LOADS When figuring generator set capacity requirements for installation involving motor loads, do not overlook the high current demanded by the motor during start-up. The “In-Rush” of starting current may be 2 to 5 times higher than that required when the motor reaches normal operating speed. Reserve capacity must be allowed for in rush demands plus other loads, which could be on the line as the motor starts.

- Page 29 APPLIANCE LOADS Generator sets in recreational vehicles are often used to supply AC voltage for appliances. With the exception of a resistance-type load such as a water heater, requirements for appliances are usually low. However, such loads must not be overlooked when calculating the total wattage requirements. To avoid an overload situation, reserve capacity should also be calculated for unanticipated appliance loads.

- Page 36 PT-ECU-63 ENGINE CONTROL MODULE 1) Generator Main Switch must be in the ON position. 2) Hold Start/Stop Switch for 1 second and release. 3) Glow Plugs will preheat for 8 seconds. LED flashes slowly. 4) Preheating will cease during engine cranking cycle. LED continues flashing. 5) Engine begins an 8 seconds crank cycle, After 4 seconds of cranking the PT-ECU-63 will check for an AC signal from the generator.

Need help?

Do you have a question about the PT-30KSI and is the answer not in the manual?

Questions and answers