Rational iCombi Pro Manual

- Original instructions for use (188 pages) ,

- Original installation manual (108 pages) ,

- Original installation instructions (100 pages)

Advertisement

- 1 SERVICE REFERENCE iCombi

- 2 FUNCTION LEVEL

- 3 SERVICE LEVEL

- 4 REPLACING THE CPU PCB

- 5 CALIBRATION / SELF - TEST

- 6 CALIBRATION ERRORS

- 7 ERROR CODE

- 8 CPU PCB A11: DIAGNOSTIC LED

- 9 I/O BOARD A10: DIAGNOSTIC LED

- 10 ESTL A15/A16: DIAGNOSTIC LED (3 LEDS A, B, C)

- 11 SAFETY TEMPERATURE SWITCH-OFF OR SENSOR FAULT (8X LED)

- 12 ESTL ELECTRONICS FAULT (16X LED)

- 13 ON/OFF SWITCH: STATUS LED

- 14 Documents / Resources

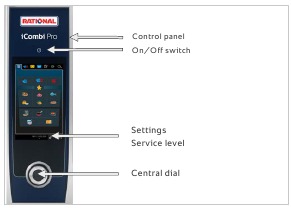

SERVICE REFERENCE iCombi

| Wi-Fi connected |

| no Wi-Fi connection working |

| LAN connected |

| no LAN connection working |

| Unit connected with ConnectedCooking |

| Connected Cooking is available, but not connected |

| Demo mode active |

| Energy optimisation active |

| USB connection was detected |

FUNCTION LEVEL

MyDisplay password: RAdmin

SERVICE LEVEL

Up to LM100-17.0.30:

Service level password: TECLEVEL

From LM100-17.3.x:

- Scan the QR code with the PIN Creator app.

- Enter the PIN (8-digit) in the cooking system.

| Launcher | Tab | Description |

| Basic settings Settings 2 | Unit-specific settings and calibration. To apply the values, switch the unit off and on again. Note: Basic settings 2 can be changed via ConnectedCooking. |

| Notification centre | Service errors that are not assigned to a specific launcher. It is possible to reset an error. | |

| Component replacement | Maintenance history: Any exchanged components can be entered in the logbook here. | |

| Runtimes | General runtimes to the unit. | |

| Diagnosis | Serial numbers and tests of components, PCB temperatures. | |

| Software | Software versions/hardware revisions on components. | |

| Service error | Service history for module errors. |

| Diagnosis | Real-time data: All sensors and actuators of the module are checked for their current status. | |

| Module test | Short programme for detecting errors in the steam system, such as problems with steam saturation. | |

| Function test | Test of all components of the corresponding module. | |

| Runtimes | Runtimes for module-specific components and modes. | |

| Volume measurement | Possibility to redetermine the steam generator volumes. | |

| Service error | ...see "Steam" launcher |

| Diagnosis | ||

| Function test | ||

| Runtimes | ||

| Motor position | Fan motors can be tested and repositioned using drag & drop. | |

| Service error | ...see "Steam" launcher |

| Diagnosis | ||

| Function test | ||

| Runtimes | ||

| Calibration values | Displays the calibration values. | |

| Service error | ...see "Steam" launcher |

| Diagnosis | ||

| Module test | A short programme (10-20 min) to reset iCare System errors. Start before or after the cause of the error has been rectified. Test of the circulating pump M17. Process is aborted unconditionally. | |

| Function test | ...see "Steam" launcher | |

| Runtimes | ||

| Service error | ...see "Steam" launcher |

| Gas parameters | Gas speeds, CO 2 target values, CO 2 screw lengths and change of gas type. | |

| Runtimes | ...see "Steam" launcher | |

| Flue gas analysis | Start of the flue gas analysis for all burners. |

REPLACING THE CPU PCB

- Unit disconnected from mains voltage

- Remove micro SD card

- Replace CPU PCB

- Insert micro SD card

- Switch on the unit

- iCombi Pro-Homescreen visible

- Unit installs software backup from micro SD card to the CPU PCB

- Update unit with the latest software

Pict. 1: # 87.01.757

CALIBRATION / SELF - TEST

A self-test is necessary:

- for a new installation.

- if the CPU PCB A11 and the micro SD card need to be replaced at the same time.

- if the unit has undergone a dry calibration and is connected to the water supply at a later point in time (Service 63).

A calibration is necessary for:

- the following service work: as soon as the fan wheel has been removed, installation of a new air baffle, modification/type change of the hinging racks

- customer complaints about uneven cooking results (but only after checking the installation conditions)

- subsequent changes to the installation conditions for extractor hoods or Combi-Duo subsequent change of the installation site with a change of the installation altitude by more than 300 metres (otherwise only a recalibration is recommended)

Start conditions: Cooking cabinet sensor B1, control sensor B2, humidity sensor B4: < 40°C. In order to achieve the best possible calibration values, a closed GN container should be inserted 20 mm deep with the open side down in the middle in front of each fan wheel.

The calibration values are determined during the self-test or calibration and stored on the SD card and PCB.

After a successful self-test, a flue gas analysis must be carried out for gas units!

CALIBRATION ERRORS

The following calibration errors can occur during the self-test or a manual calibration:

(Error step | Error code)

- (1 | 2) B1 too hot (1 | 4) B2 too hot (1 | 8) B4 too hot; Combination of error codes is possible!

- (2 | 1) Differential pressure too low (2 | 2) Differential pressure too high; Check P1

- (4 | 1), (10 | 1), (15 | 1) Determined calibration value too low n (4 | 2), (10 | 2), (15 | 2) Determined calibration value too high; Check the hose

- (X | 999) Timeout in calibration step; E.g.: cabinet door open, check heating register/SSR

- Calibration step 20: Calibration has been successfully completed

ERROR CODE

Beware of electric shock, even when the unit is switched off:

I/O power supply unit (A10), pump PCB (A13), eSTL (A15/A16) and solenoid valve block.

| Service | Description |

| 10 | SC pump, Combi water box, pump-off hose |

| 11 | Level electrode, CDS sensor flow rate, I/O board |

| 12 | Check CDS sensor |

| 13 | Check level electrode |

| 14 | Check level electrode, measure conductivity of water |

| 19.1 | Check SD card |

| 20.x | Thermocouple: -1: cooking cabinet B1; -2: control B2; -4: humidity B4; -8: steam generator B5; -16: cooking cabinet bottom B9 (floor units); -32: installation area B10 (XS); -64: cooling fan iCareSystem AutoDose |

| 25 | No increase in performance at the fan motor when the water jet hits: Check water supply, pressure, hoses, CDS sensor, position of hinged racks / mobile oven racks |

| 26 | Only XS: Ball valve does not open; test in the function test, replace if necessary |

| 27 | Only XS: Ball valve does not close; test in the function test, replace if necessary |

| 28.x | Thermal element: -1: steam generator too hot (B5 > 170°C [338°F]); -2: cooking cabinet too hot (B1 > 350°C [662°F]); -4: steam generator (B5 < 2°C [36°F], heating possible again from 4°C [39°F]) |

| 29 | CPU board temperature too high (> 75°C [167°F]) |

| 30 | Humidity control error; Check differential pressure sensor P1 |

| 31.x | Thermocouple core temperature B3: -1: check cooking cabinet core probe; -2: cooking cabinet core probe emergency mode; -11/12: check USB CT 1 / emergency mode; -21/22: check USB CT 2 / emergency mode |

| 32.x | Fault in combustion system or gas supply (y = combustion system): -1.y (22: HA top, 32: steam, 42: HA bottom): 5x unsuccessful ignition process -2.y (17/18/49: HA top, 27/28/52: steam, 37/38/55: HA bottom): Flame current measured with gas valve closed -3.y (19: HA top, 29: steam, 39: HA bottom): Burner went out 5 times during the burning phase -4.y (20: HA top, 30: steam, 40: HA bottom): The speed of the gas blower deviates from the target speed by more than 150 rpm |

| 33.x | Error in the control of the combustion system: -1: Accumulation of combustion system errors; -2: Automatic burner control initialised with incorrect gas speeds (=0 or Min<Start<Max not fulfilled); -3: Mains frequency outside 40...70 Hz; -4: Phase and neutral conductor mixed up; -5: Check automatic ignition controller |

| 34.x | Bus signal missing: -1: motor up; ‑2: motor centre; ‑4: motor bottom; ‑8: pump PCB; ‑16: I/O power supply; ‑32: ignition box; ‑256: chemical controller |

| 35 | UltraVent: Bus signal / internal communication |

| 35.x | UltraVent error: -1: voltage missing; -2: filter detection faulty; -3: check thermocouple control; -4: check thermocouple motor protection; -5: pre-warning (change filter) -6: dirt in filter (immediate replacement); -7: Filter not inserted/no differential pressure measured |

| 36 | Check differential pressure sensor (no signal output of 0.5V; check input signal 12V at P1); P1 must be installed horizontally |

| 37 | Climate control malfunction: Check hose connections |

| 40 | iCombi Pro: Error in iCareSystem, hose to steam generator (partially) blocked or kinked iCombi Pro with iCareSystem AutoDose option: Error in iCareSystem, hose to steam generator (partially) blocked or kinked, steam generator outlet (Y21) does not open (valve jams and always remains closed) |

| 42.x | Incorrect water flow or incorrect flow detection via valve: -1: filling Y1 to steam generator; -2: control Y2 to control solenoid; -3: moistening Y3 to moistening nozzle; -4: care Y4 to care container; -6: flushing Y14 to control box |

| 43 | Solenoid valve does not close |

| 44 | Malfunction steam heating system |

| 45.x | Malfunction on: -1: cartridge valve 1; -2: cartridge valve 2; -3: cartridge valve 3; -4: cartridge valve 4; -5: outlet cleaner box; -6: outlet steam generator |

| 46.1 | SC-pump (M4): incorrect rpm/power consumption |

| 47.1 | Wastewater pump (M15): incorrect rpm/power consumption |

| 48.1 | Circulation pump (M17): incorrect rpm/power consumption |

| 49.1 | Care pump (M18): incorrect rpm/power consumption |

| 50 | Real time clock (date and time) |

| 51 | Check battery, replace if necessary |

| 52.x | LED door lighting error: -1: hinge side; -2: handle side |

| 53.1 | Mixing pump (M29): incorrect rpm/power consumption |

| 54 | Malfunction conductivity sensor iCareSystem AutoDose |

| 55 | Error fan motor top: Fan motor top does not reach the set speed. Heating request is blocked. |

| 56 | Error fan motor middle: Fan motor middle does not reach the set speed. Heating request is blocked. |

| 57 | Error fan motor bottom: Fan motor bottom does not reach the set speed. Heating request is blocked. |

| 58 | iCareSystem AutoDose flap faulty |

| 59.x | Cartridge detection micro switch defective: -1: slot 1 (S17 – S18); -2: slot 2 (S19 – S20); -3: slot 3 (S21 – S22); -4: slot 4 (S23 – S24) |

| 60 | Will be replaced by Service 33.2. |

| 63 | The unit detects water for the first time after a dry calibration after a self-test without water: Restart calibration. |

| 70.x | -1: Cooling fan failure; -5: Cooling fan failure iCareSystem AutoDose |

| 71.x | -1: Power supply unit fault; -2: Undervoltage power supply unit |

| 72 | eSTL safety chain has tripped. For cause of trip, see "eSTL A15/A16: Diagnostic LED" |

| 73.x | Overtemperature fault: -1: Motor top; -2: Motor bottom; -4: Motor centre; -8: Pump PCB; -16: I/O power supply unit; -32: Automatic ignition controller; -1024: Overtemperature of the top Combi-Duo unit |

| 75.x | Internal data communication (I²C) faulty; -1: Energy optimization not working; -2: 4-way relay PCB not working; -3: Cleaning PCB (XS) not working |

| 76.x | Only US: -1: Voltage limited; -2: Internal check failed; -3: Incorrect voltage setting; -4: Too many channels; -5: Incorrect channels; -6: Incorrect time; -7: Hardware error |

| 110 | Check SC pump (fault occurs while care solution is in the steam generator) |

| 120 | Level electrode without signal while care solution is in the steam generator; |

| 130 | Manual descaling necessary (filling volume below 80% of the reference volume) |

| 140.x | Permanent fault in the gas supply or in the hot air gas combustion system: -4: Pre-warning for cooking operation block; -8: Cooking operation block |

| 201 | Carry out motor positioning |

| 201 | Carry out motor positioning |

CPU PCB A11: DIAGNOSTIC LED

| Ethernet activity 2 LEDs (D2001 - green, D2002 - yellow) | |

| Green LED – D2001: on: 100Mbit off: 10Mbit | Yellow LED – D2002: off: no physical connection on: connected, no data transfer flashing: connected & data transfer |

| Fault: 1 LED (D5001 - red) | |

| Voltage display: 1 LED (D2008 – green): 12V voltage input | |

I/O BOARD A10: DIAGNOSTIC LED

Red diagnostic LED on the rear side A10:

| Code 1 | 1x flash | Input voltage error |

| Code 2 | 2x flashes | Communication error A10 processor |

| Code 3 | 3x flashes | Fault on/off processor |

| Code 4 | 4x flashes | Input voltage too high |

| Code 5 | 5x flashes | Input voltage too low |

| Code 6 | 6x flashes | Mains frequency outside the tolerance |

| Code 7 | 7x flashes | Self-test A10 failed |

3 green diagnostic LED on the front side A10: See training manual.

ESTL A15/A16: DIAGNOSTIC LED (3 LEDS A, B, C)

For a detailed fault analysis: See error description S_72.

SAFETY TEMPERATURE SWITCH-OFF OR SENSOR FAULT (8X LED)

| Blink code | Description | Graphic representation |

| 1 | Connection to eSTL sensor steam lost |  |

| 2 | Short circuit on eSTL sensor steam |  |

| 3 | Plausibility check on the eSTL steam sensor |  |

| 4 | Safety temperature cutoff steam |  |

| 5 | Connection to eSTL sensor hot air interrupted |  |

| 6 | Short circuit on eSTL sensor hot air |  |

| 7 | Plausibility check on eSTL hot air sensor |  |

| 8 | Hot air safety temperature cut-off |  |

ESTL ELECTRONICS FAULT (16X LED)

Description

After the start flashing signal, the eSTL electronics flashes a total of 16 times.

If, during the 2nd, 13th, 14th or 15th flash, both red LEDs also light up, the power supply (voltage or frequency) was out of tolerance for more than 10 seconds (frequently during alternator operation, for example).

Description

After the start flashing signal, the eSTL electronics flashes a total of 16 times. If the power supply is OK and a different blink code applies, an internal error of the eSTL electronics has been detected

After solving the problem: Reset the eSTL, press the reset button for three seconds.

ON/OFF SWITCH: STATUS LED

3 possible status displays:

| LED status | Status | Error |

| Green steady 5-6 seconds | The unit is switched off. The unit should be switched on | No 12V detected by I/O board |

| Yellow Permanently lit for 5-6 seconds | The unit is switched on. Unit should be switched off | CPU detects 12V from I/O board |

| Green/Yellow LED flashes alternately | The unit is switched on. | Button detects dirt on on/off switch |

Documents / ResourcesDownload manual

Here you can download full pdf version of manual, it may contain additional safety instructions, warranty information, FCC rules, etc.

Advertisement

Need help?

Do you have a question about the iCombi Pro and is the answer not in the manual?

Questions and answers