Kreg Rip-Cut KMA2685 Manual

- Owner's manual (12 pages) ,

- Owner's manual (6 pages)

Advertisement

- 1 Rip-Cut Components

-

2

Assembly

- 2.1 Step 1: Connect the Edge Guide to the Rail

- 2.2 Step 2: Orient the Filler Strip

- 2.3 Step 3: Mount your Circular Saw on the Sled

- 2.4 Step 4: Check the Position of the Cursor

- 2.5 Step 5: Reinstall the Indexing Stop

- 2.6 Step 6: Slide the Sled onto the Rail

- 2.7 Step 7: Align the Cursor and Determine the Narrowest Cut

- 3 Using Your Rip-Cut

- 4 General Safety Guidelines

- 5 Documents / Resources

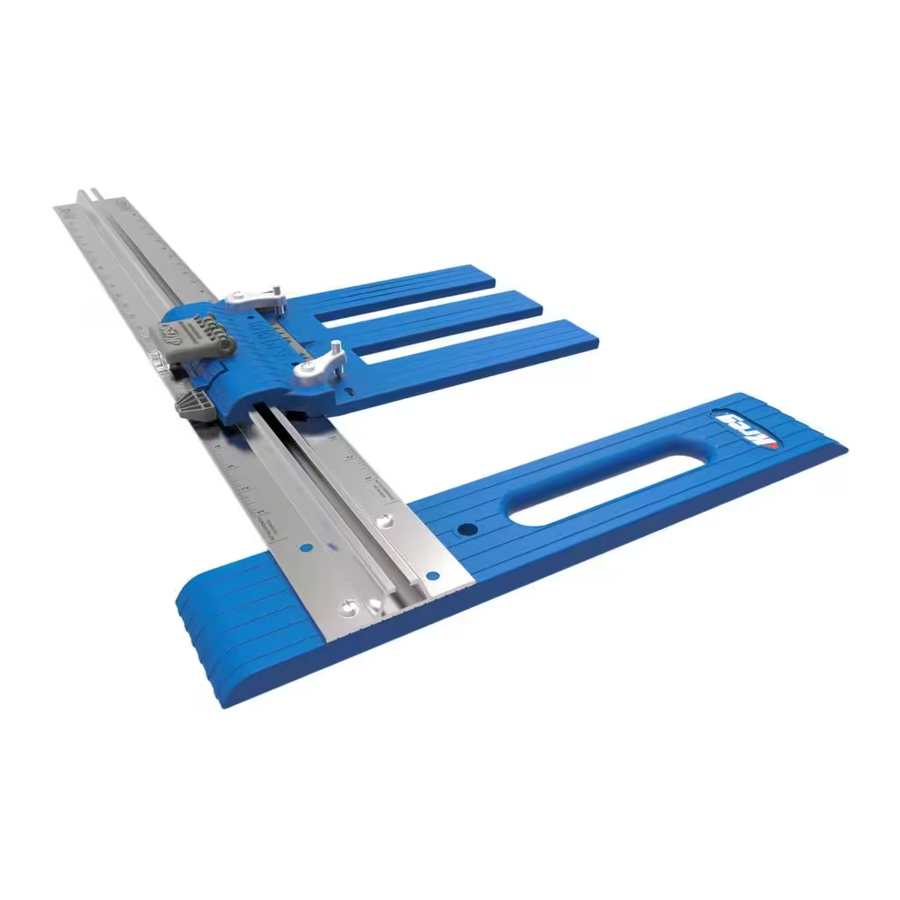

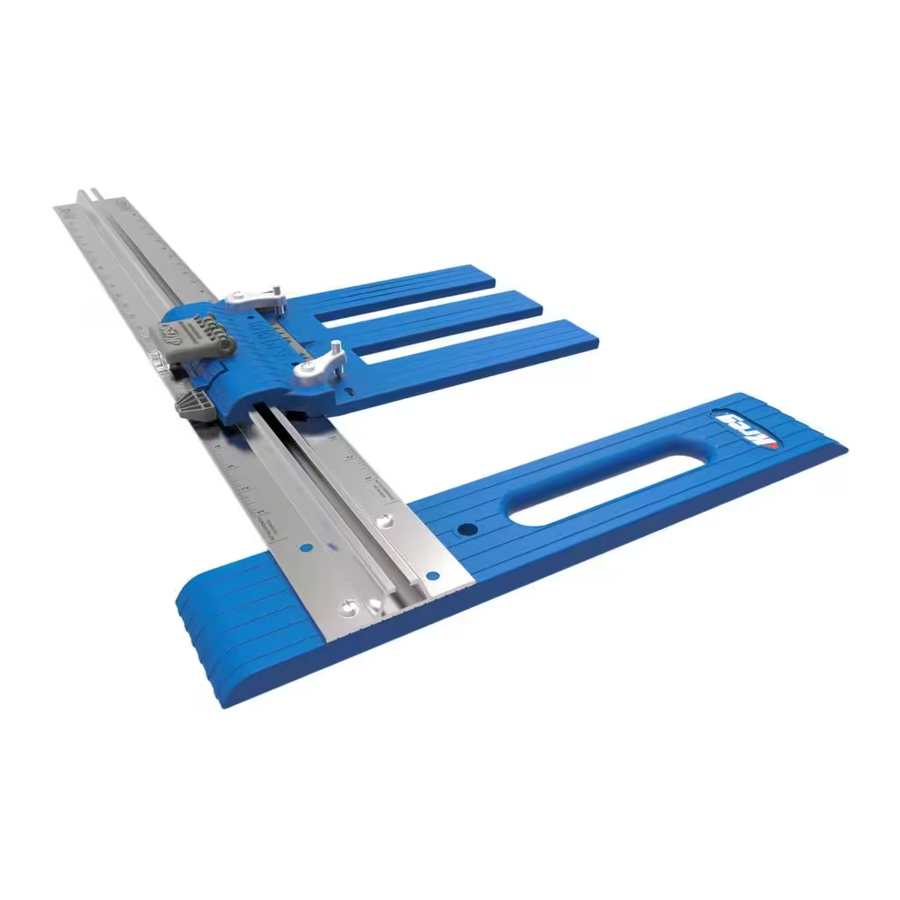

Rip-Cut Components

Assembly

Step 1: Connect the Edge Guide to the Rail

Remove the clear tape covering the recess in the edge guide (A), remove the two self-tapping screws (B), and use them to secure the edge guide to the rail (C).

Orient the edge guide for right-hand or left-hand operation as shown.

Step 2: Orient the Filler Strip

The filler strip (D) on the sled (E) is shipped with the angled ribs facing up. These ribs support a saw base with an angled leading edge, keeping the saw base flat on the sled when the set screws (F) in the base-plate clamps (G) are tightened.

For a saw base with a flat leading edge, lift the filler strip from the sled recess with the tip of a screwdriver, turn it over to expose the flat face, and press it into the recess.

Step 3: Mount your Circular Saw on the Sled

Remove the indexing stop (H) from the sled (E). Loosen the set screws (F) in the base-plate clamps (G) and slide your saw base plate under them.

Position the saw on the sled with the front of the saw base plate against the step at the front of the sled. For saws with the blade on the left-hand end of the motor, center the blade in the left sled slot. For saws with the blade on the right-hand end of the motor, center the blade in the right sled slot. To accommodate different saw base-plate configurations, there are two holes for attaching each base-plate clamp to the sled. For the most secure clamping, choose the holes that provide the widest spacing allowed by your saw. The clamps can be oriented at an angle. Tighten the set screws onto the saw base plate to securely hold the saw but do not over-tighten. Make sure the saw-blade guard operates freely.

Disconnect the saw from power before mounting it on the sled.

Step 4: Check the Position of the Cursor

There are two positions on the sled for the cursor (K) that correspond to the two sled slots. Position the cursor in the holder in front of the saw blade. To switch cursor position, press down on the holder lock, slide the cursor out of the holder and reinstall it in the other holder.

Step 5: Reinstall the Indexing Stop

The indexing stop (H) allows you to remove the saw from the sled assembly and then re-mount it in exactly the same position. Place the indexing stop against the side of the saw base on the same side as the cursor (K) and secure it to the sled (E) with the machine screw (I) and nut (J). For maximum positioning flexibility, the sled is slotted and the indexing stop rotates 180°.

Step 6: Slide the Sled onto the Rail

With your saw clamped to the sled (E), raise the handle (M) to the upright position and slide the sled onto the rail (C), inserting the wedge (L) into the rail channel. The saw and the edge guide (A) should extend from the same edge of the rail.

Step 7: Align the Cursor and Determine the Narrowest Cut

Rotate the saw blade guard up and slide the sled (E) along the rail (C) until the blade just touches the edge guide (A). Lock the sled in place by pressing down on the handle (M). The handle does not need to be completely horizontal to lock securely. Press down on the cursor lock and align the red cursor (K) with the zero mark on the rail scale. The minimum safe cut may be greater than 1'.

On the scale, the area between zero and 1' [25mm] is marked Not Recommended, See Manual. On most saws, the edge guide interferes with blade-guard operation on cuts of less than 1' [25mm], so these cuts should not be attempted. After aligning the cursor, verify the minimum safe cut width by moving the sled away from the edge guide until the blade guard functions without interference.

Using Your Rip-Cut™

- For the best results, install a 40-tooth blade or better on your saw.

- With the saw mounted on the sled, adjust the depth of cut so the blade will protrude ⅛' [3mm] through the workpiece during the cut.

- Release the wedge lock and slide the sled along the rail until the cursor aligns with the desired dimension on the scale. Engage the wedge lock.

- Completely support the workpiece and cutoff with 2x4s or 2' [50mm]-thick rigid foam insulation laid flat on the floor.

- Connect your saw to power. With one hand on the edge guide and the other holding the saw, press the edge guide against the edge of your workpiece and make your cut, moving the edge guide and saw forward at the same speed throughout the entire cut. Allow the saw blade to come to a complete stop before lifting the Rip-Cut™ from the workpiece.

![Kreg - Rip-Cut KMA2685 - Using Your Rip-Cut™ Using Your Rip-Cut™]()

When making narrow cuts, make sure the hand holding the edge guide does not contact the blade.

General Safety Guidelines

When using electric tools, always follow the safety precautions below to reduce the risk of fire, electric shock, and personal injury. Read all these instructions before attempting to operate this product.

SAVE THESE INSTRUCTIONS.

Work area safety

- Keep work area clean and well lit. Cluttered or dark areas invite accidents.

- Don't use power tools in a dangerous environment. Don't use power tools in damp or wet locations, or expose them to rain.

- Do not operate power tools in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Power tools create sparks that can ignite the fumes or dust.

- Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

- Make your workshop child proof. Use padlocks, master switches, or remove starter keys.

Electrical safety

- Ground electric tools. If the tool is equipped with a three- prong plug, it must be plugged into a grounded three-hole electrical outlet. If the proper outlet is not available, have one installed by a qualified electrician. Never remove the third prong or modify the provided plug in any way.

- Do not expose power tools to rain or wet conditions. Water entering a power tool increases the risk of electric shock.

- Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

- Use a proper extension cord and make sure it is in good condition. When using an extension cord, be sure to use one heavy enough to carry the current your power tool draws. An undersized cord causes a drop in line voltage resulting in loss of power and overheating. Table 1 shows the correct cord gauge to use depending on cord length and tool nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the gauge number, the heavier the cord.

- When operating electric tools, avoid body contact with grounded or earthed surfaces such as pipes, radiators, kitchen ranges, and refrigerators. Contact with a grounded surface increases the risk of electric shock.

Personal safety

- Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A moment of inattention while operating power tools can result in serious personal injury.

- Always wear safety glasses. Everyday eyeglasses are not safety glasses. Safety glasses have specially constructed lenses, frames, and side shields.

- Use safety equipment. Use a face or dust mask when the cutting operation is dusty. Safety equipment such as a dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions reduces personal injuries.

- Avoid accidental starting. Make sure the switch is in the off-position before plugging in. Carrying power tools with your finger on the switch or plugging in power tools that have the switch on invites accidents.

- Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left attached to a rotating part of the power tool can result in personal injury.

- Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected situations.

- Secure workpieces. Use clamps or a vise to hold work when practical. This is safer than using your hand and it frees both hands to operate the tool.

- Never stand on the machine. Serious injury can occur if the tool tips or if the cutting tool is unintentionally contacted.

- Dress properly. Do not wear loose clothing or jewelry. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewelry or long hair can be caught in moving parts. Roll up long sleeves to the elbow. Wear protective hair covering to contain long hair.

- If devices are provided for the connection of dust extraction and collection equipment, ensure these are connected and properly used. Use of these devices reduces dust-related hazards.

Power tool use and care

- Keep guards in place and in working order.

- Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and safer at the rate for which it was designed.

- Use the right tool. Don't force a tool or attachment to do a job for which it was not designed.

- Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is dangerous and must be repaired.

- Disconnect the plug from the power source and/ or the battery pack from the power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

- Never leave a tool running unattended. Turn power off. Do not leave the tool until it comes to a complete stop.

- Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool and these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

- Maintain power tools. Check for misalignment or binding of moving parts, broken parts, and any other condition that can affect power tool operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly maintained power tools.

- Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

- Use the recommended speed for the cutting tool or accessory and workpiece material.

- Only use parts and accessories recommended by the manufacturer. Consult the owner's manual for recommended accessories. Using improper accessories can cause personal injury.

- Use the power tool, accessories, and tool bits in accordance with these instructions and in the manner intended for the particular type of power tool, taking into account the working conditions and the work to be performed. Use of the power tool for operations different from those intended can result in a hazardous situation.

Service

- Have your power tool serviced by a qualified repair person using only identical replacement parts. This ensures that the safety of the power tool is maintained.

SAFETY INSTRUCTIONS SPECIFIC TO USING THE RIP-CUT™

- Before using the Rip-Cut™, read, understand, and follow the safety warnings and operation instructions included with this product and provided by your saw manufacturer. Keep all guards and safety devices in place.

- Wear proper eye, ear, and respiratory protection when operating your saw.

- Use a sharp blade designed for the type of material you are cutting.

- Always disconnect your saw from power before making adjustments to the saw or Rip-Cut™.

- Check the cursor alignment before you cut.

- Ensure that the saw blade will not contact the edge guide during the cut.

- Do not attempt a cut when any part of the Rip-Cut™ sled interferes with the operation of the saw blade guard.

- Fully support both the workpiece and the cutoff piece to prevent binding and kickback.

- Adjust the depth of cut so the saw blade protrudes1⁄8" [3mm] through the workpiece during the cut.

- Keep your hands away from the saw blade during operation. Do not reach under the workpiece while cutting.

- Secure your workpiece to ensure it doesn't move during the cut.

- Do not use excessive force when cutting. Maintain a steady and controlled pace.

- Allow the saw blade to come to a complete stop before lifting the Rip-Cut from your work piece.

- Maintain your tools and accessories. Check for misalignment or binding of moving parts, loose fasteners, broken parts, and any other condition that may affect safe operation. If an unsafe condition is discovered, correct it before use.

Kickback

Kickback is a sudden reaction to a pinched, bound, or misaligned saw blade, causing an uncontrolled saw to lift up and out of the workpiece toward the operator.

Causes of kickback

- When the blade is pinched or bound tightly by the kerf closing in, the blade stalls and the motor reaction drives the unit rapidly back toward the operator.

- If the blade becomes twisted or misaligned in the cut, the teeth at the back edge of the blade can dig into the top surface of the wood causing the blade to climb out of the kerf and propel the saw back toward the operator.

Preventing kickback

Kickback is the result of tool misuse and/or incorrect operating procedures or conditions and can be avoided by taking proper precautions.

- Maintain a firm grip with both hands on the saw and position your body and arms to resist kickback forces. Kickback forces can be controlled by the operator if proper precautions are taken.

- When blade starts to bind, or when interrupting a cut for any reason, release the trigger and hold the saw motionless in the material until the blade comes to a complete stop. Never attempt to remove the saw from the work or pull the saw backward while the blade is in motion. Investigate and take corrective actions to eliminate the cause of blade binding.

- When restarting a saw in the workpiece, center the saw blade in the kerf and check that saw teeth are not engaged in the material. If the saw blade is binding, the blade may climb out of the workpiece and kickback as the saw is restarted.

- Support large panels to minimize the risk of blade pinching and kickback. Large panels tend to sag under their own weight. Supports must be placed under the panel on both sides of the cut: near the cutline and near the edge of the panel.

- Do not use a dull or damaged blade. A dull or improperly sharpened blade produces a narrow kerf, causing excessive friction, blade binding, and kickback.

- Blade depth and bevel adjusting locks must be tight and secure before making a cut. If blade adjustment shifts while cutting, it may cause binding and kickback.

- Use extra caution when making a plunge cut into existing walls, floors, or other blind areas. The protruding blade may contact unseen objects that can cause kickback.

Guidelines for extension cord use

Extension cords are only to be used for temporary purposes. They do not replace the need for installation of outlets and proper wiring where necessary.

In the shop and on construction sites:

- Extension cords with an equipment grounding conductor must be used at all times.

- Extension cords must be protected from damage, and not run through doorways or windows where the doors or windows can close, causing damage to the cord.

- Extension cords must be a minimum of 16 AWG and be rated for the equipment in use.

- Extension cords must be periodically inspected to ensure that the insulation and conductivity of the wires are not compromised.

- Extension cords should not be run through water or allowed to have connections that may be exposed to accumulated water.

TABLE 1

| Nameplate Amperes @120 V | Extension Cord Length | |||||

| 25' | 50' | 75' | 100' | 150' | 200' | |

| Recommended Wire Gauge | ||||||

| 0 -5 | 16 | 16 | 16 | 14 | 12 | 12 |

| 5.1 - 8 | 16 | 16 | 14 | 12 | 10 | NR |

| 8.1 -12 | 14 | 14 | 12 | 10 | NR | NR |

| 12.1 - 16 | 12 | 12 | NR | NR | NR | NR |

NR – Not Recommended

This product can expose you to chemicals including Acrylonitrile and other chemicals, which are known to the State of California to cause cancer and reproductive harm. For more information go to www.P65Warnings.ca.gov.

800.447.8638

Documents / Resources

References

Download manual

Here you can download full pdf version of manual, it may contain additional safety instructions, warranty information, FCC rules, etc.

Advertisement

Need help?

Do you have a question about the Rip-Cut KMA2685 and is the answer not in the manual?

Questions and answers