Summary of Contents for DEMA GC Valves H211 Series

- Page 1 Revision 3, December 8, 2022 Service and Installation For Standard GC Valves GC Valves, LLC. 456 Crompton Street Charlotte, North Carolina 28273 Ph: (800)-828-0484, Fx: (704)-973-9526...

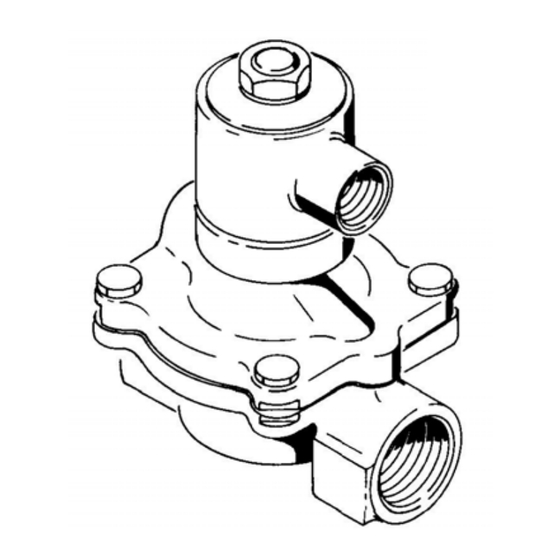

- Page 3 Nut (106198E) GC Valves...

-

Page 6: Operation

H401 -- Service and Installation -- 4/24/18 DESCRIPTION COIL REPLACEMENT H401 Series are 2-way piloted piston operated solenoid valves Turn off the electrical power supply to the solenoid before with Standard stainless steel bodies. Positive shutoff is disconnecting the coil lead wires. assured by using spring loaded plunger and synthetic seating Incorrect coil reassembly can cause coil burnout. -

Page 7: Troubleshooting

SERVICE Disassembly and Assembly ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the Disassembly and Assembly instructions, complete valve must be replaced by a trained and experienced service-person. ________________________________________________ Unscrew the hex nut (1). - Page 8 DESCRIPTION K-13 Lever action operated three-way valves are two-wire, current failure, single magnetic packless valves. They are designed to direct the flow of oil, water, refrigerants and similar fluids. Applications include control of fluid to piston and diaphragm operators, distribution of fluids from a common source pneumatic pumping and selection of fluid sources.

- Page 9 INSTALLATION Mark rocker support and valve body to assure correct All valves including those having "W" designation (rainproof reassembly, and remove rocker support from body by taking out enclosure) in 5th digit position of valve catalog number must be two machine screws and lock washers. mounted on a horizontal pipe line with solenoid in an upright If necessary to remove valve mechanism, keep valve position.

- Page 10 NS201 (AC) -- Service and Installation -- 12/14/2016 DESCRIPTION The NS201 Series Solenoid Valves are 2-way, normally REBUILD KIT closed, piloted, zero differential general purpose valves The Rebuild Kit contains a plunger/spring/seat disc assembly, specifically designed for drinking water and other food plunger tube assembly, O-rings and adapter ring.

- Page 11 SERVICE Disassembly ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person. ________________________________________________ Unscrew the hex nut (1).

- Page 12 NS201 F, G, & H (AC) -- Service and Installation -- 3/15/19 DESCRIPTION The Rebuild Kit contains a plunger/spring/seat disc assembly, The NS201 Series Solenoid Valves are 2-way, normally plunger tube assembly, O-rings and adapter ring. closed, piloted, zero differential general purpose valves. All stainless steel or brass construction with synthetic seating and REPAIR KIT sealing materials make them suitable for use with a variety of...

- Page 13 SERVICE Disassembly ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person. ________________________________________________ Unscrew the hex nut (1).

- Page 14 NS201 (DC) -- Service and Installation -- 12/14/2016 DESCRIPTION The NS201 Series Solenoid Valves are 2-way, normally REBUILD KIT closed, piloted, zero differential general purpose valves The Rebuild Kit contains a plunger/spring/seat disc assembly, specifically designed for drinking water and other food plunger tube assembly, O-rings and adapter ring.

- Page 15 SERVICE Disassembly ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person. ________________________________________________ Unscrew the hex nut (1).

- Page 16 NS201 F, G, & H (DC) -- Service and Installation -- 3/15/19 DESCRIPTION The NS201 Series Solenoid Valves are 2-way, normally REBUILD KIT closed, piloted, zero differential general purpose valves. All The Rebuild Kit contains a plunger/spring/seat disc assembly, stainless steel or brass construction with synthetic seating and plunger tube assembly, O-rings and adapter ring.

- Page 17 SERVICE Disassembly ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person. ________________________________________________ Unscrew the hex nut (1).

- Page 18 NS211 (AC) -- Service and Installation -- 12/14/2016 DESCRIPTION REBUILD KIT The NS211 Series Solenoid Valves are 2-way, normally The Rebuild Kit contains a plunger/spring/seat disc assembly, closed, piloted, general purpose valves specifically designed plunger tube assembly, O-rings and adapter ring. for drinking water and other food products.

- Page 19 SERVICE Disassembly ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person. ________________________________________________ Unscrew the hex nut (1).

- Page 20 NS211 (DC) -- Service and Installation -- 12/14/2016 DESCRIPTION The NS211 Series Solenoid Valves are 2-way, normally REBUILD KIT closed, piloted, general purpose valves specifically designed The Rebuild Kit contains a plunger/spring/seat disc assembly, for drinking water and other food products. All stainless steel or plunger tube assembly, O-rings and adapter ring.

- Page 21 SERVICE Disassembly ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person. ________________________________________________ Unscrew the hex nut (1).

- Page 22 NS301 - Service and Installation - 12/14/2016 DESCRIPTION COIL REPLACEMENT The NS301 Series Solenoid Valves are 2-way, normally Turn off the electrical power supply to the solenoid before closed, direct acting, general purpose valves specifically disconnecting the coil lead wires. designed for drinking water and other food products.

- Page 23 SERVICE DISASSEMBLY AND REPAIR KIT INSTALLATION ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person.

- Page 24 REBUILD KIT INSTALLATION AND ASSEMBLY ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person.

- Page 25 S201 (AC) -- Service and Installation -- 11/1/2016 DESCRIPTION REBUILD KIT The S201 Series Solenoid Valves are 2-way, normally closed, The Rebuild Kit contains a plunger/spring/seat disc assembly, piloted, zero differential general purpose valves. All stainless plunger tube assembly, O-rings and adapter ring. steel, brass or Noryl construction with synthetic seating and sealing materials make them suitable for use with a variety of REPAIR KIT...

- Page 26 SERVICE Disassembly ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person. ________________________________________________ Unscrew the hex nut (1).

- Page 27 S201 F, G, & H (AC) -- Service and Installation -- 4/24/18 DESCRIPTION The S201 Series Solenoid Valves are 2-way, normally closed, REBUILD KIT piloted, zero differential general purpose valves. All stainless The Rebuild Kit contains a plunger/spring/seat disc assembly, steel or brass construction with synthetic seating and sealing plunger tube assembly, O-rings and adapter ring.

- Page 28 SERVICE Disassembly ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person. ________________________________________________ Unscrew the hex nut (1).

- Page 29 S201 (DC) -- Service and Installation -- 11/1/2016 DESCRIPTION REBUILD KIT The S201 Series Solenoid Valves are 2-way, normally closed, The Rebuild Kit contains a plunger/spring/seat disc assembly, piloted, zero differential general purpose valves. All stainless plunger tube assembly, O-rings and adapter ring. steel, brass or Noryl construction with synthetic seating and sealing materials make them suitable for use with a variety of REPAIR KIT...

- Page 30 SERVICE Disassembly ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person. ________________________________________________ Unscrew the hex nut (1).

- Page 31 S201 F, G, & H (DC) -- Service and Installation -- 4/24/18 DESCRIPTION The S201 Series Solenoid Valves are 2-way, normally closed, REBUILD KIT piloted, zero differential general purpose valves. All stainless The Rebuild Kit contains a plunger/spring/seat disc assembly, steel or brass construction with synthetic seating and sealing plunger tube assembly, O-rings and adapter ring.

- Page 32 SERVICE Disassembly ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person. ________________________________________________ Unscrew the hex nut (1).

- Page 33 S202 (DC) -- Service and Installation -- 11/1/2016 DESCRIPTION REBUILD KIT The S202 Series Solenoid Valves are 2-way, normally open, The Rebuild Kit contains a plunger/spring/seat disc assembly, piloted, zero differential general purpose valves. All stainless plunger tube assembly, O-rings and adapter ring. steel, brass or Noryl construction with synthetic seating and sealing materials make them suitable for use with a variety of REPAIR KIT...

- Page 34 SERVICE Disassembly ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person. ________________________________________________ Unscrew the hex nut (1).

- Page 35 S202 (AC) -- Service and Installation -- 11/1/2016 DESCRIPTION REBUILD KIT The S202 Series Solenoid Valves are 2-way, normally open, The Rebuild Kit contains a plunger/spring/seat disc assembly, piloted, zero differential general purpose valves. All stainless plunger tube assembly, O-rings and adapter ring. steel, brass or Noryl construction with synthetic seating and sealing materials make them suitable for use with a variety of REPAIR KIT...

- Page 36 SERVICE Disassembly ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person. ________________________________________________ Unscrew the hex nut (1).

- Page 38 S212 (DC) -- Service and Installation -- 11/1/2016 DESCRIPTION REBUILD KIT The S212 Series Solenoid Valves are 2-way, normally open, The Rebuild Kit contains a plunger/spring/seat disc assembly, piloted, general purpose valves. All stainless steel, brass or plunger tube assembly, O-rings and adapter ring. Noryl construction with synthetic seating and sealing materials make them suitable for use with a variety of liquids, oils and REPAIR KIT...

- Page 39 SERVICE Disassembly ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person. ________________________________________________ Unscrew the hex nut (1).

- Page 40 S212 (AC) -- Service and Installation -- 11/1/2016 DESCRIPTION REBUILD KIT The S212 Series Solenoid Valves are 2-way, normally open, The Rebuild Kit contains a plunger/spring/seat disc assembly, piloted, general purpose valves. All stainless steel, brass or plunger tube assembly, O-rings and adapter ring. Noryl construction with synthetic seating and sealing materials make them suitable for use with a variety of liquids, oils and REPAIR KIT...

- Page 41 SERVICE Disassembly ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person. ________________________________________________ Unscrew the hex nut (1).

- Page 42 S211 (DC) -- Service and Installation -- 11/1/2016 DESCRIPTION REBUILD KIT The S211 Series Solenoid Valves are 2-way, normally closed, The Rebuild Kit contains a plunger/spring/seat disc assembly, piloted, general purpose valves. All stainless steel, brass or plunger tube assembly, O-rings and adapter ring. Noryl construction with synthetic seating and sealing materials make them suitable for use with a variety of liquids, oils and REPAIR KIT...

- Page 43 SERVICE Disassembly ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person. ________________________________________________ Unscrew the hex nut (1).

- Page 44 S211 (AC) -- Service and Installation -- 11/1/2016 DESCRIPTION REBUILD KIT The S211 Series Solenoid Valves are 2-way, normally closed, The Rebuild Kit contains a plunger/spring/seat disc assembly, piloted, general purpose valves. All stainless steel, brass or plunger tube assembly, O-rings and adapter ring. Noryl construction with synthetic seating and sealing materials make them suitable for use with a variety of liquids, oils and REPAIR KIT...

- Page 45 SERVICE Disassembly ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person. ________________________________________________ Unscrew the hex nut (1).

- Page 49 Nut (106198E) GC Valves...

- Page 50 GC V l GC Valves Spanner Nut (Part Number 106198E) 106198E) to remove the top plate (4). GC Valves...

- Page 51 DIN Connector GC Valves...

- Page 56 S271 (DC) -- Service and Installation -- 11/1/2016 DESCRIPTION REBUILD KIT The S271 Series Solenoid Valves are 2-way, normally closed, The Rebuild Kit contains a plunger/seat disc assembly, spring, piloted, zero differential general purpose valves. Stainless diaphragm assembly, plunger tube assembly and O-rings. steel or Brassl construction with synthetic seating and sealing materials make them suitable for use with a variety of liquids, REPAIR KIT...

- Page 57 SERVICE Disassembly ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person. ________________________________________________ Disconnect electrical connections and remove retaining screw (1).

- Page 58 S271 (AC) -- Service and Installation -- 11/1/2016 DESCRIPTION REBUILD KIT The S271 Series Solenoid Valves are 2-way, normally closed, The Rebuild Kit contains a plunger/seat disc assembly, spring, piloted, zero differential general purpose valves. Stainless diaphragm assembly, plunger tube assembly and O-rings. steel or Brass construction with synthetic seating and sealing materials make them suitable for use with a variety of liquids, REPAIR KIT...

- Page 59 SERVICE Disassembly ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person. ________________________________________________ Disconnect electrical connections and remove retaining screw (1).

- Page 60 S272 (AC) -- Service and Installation -- 12/14/18 DESCRIPTION The S272 Series Solenoid Valves are 2-way, normally open, REBUILD KIT piloted, zero differential general purpose valves. Stainless The Rebuild Kit contains a plunger/seat disc assembly, steel or Brass construction with synthetic seating and sealing spring, diaphragm assembly, plunger tube assembly and O- materials make them suitable for use with a variety of liquids, rings.

- Page 61 SERVICE-Disassembly ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person. ________________________________________________ Disconnect electrical connections and remove retaining screw (1) lockwasher (2) and spacer (3).

- Page 62 S272 (DC) -- Service and Installation -- 12/14/18 DESCRIPTION The S272 Series Solenoid Valves are 2-way, normally open, REBUILD KIT piloted, zero differential general purpose valves. Stainless The Rebuild Kit contains a plunger/seat disc assembly, steel or Brass construction with synthetic seating and sealing spring, diaphragm assembly, plunger tube assembly and O- materials make them suitable for use with a variety of liquids, rings.

- Page 63 SERVICE-Disassembly ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person. ________________________________________________ Disconnect electrical connections and remove retaining screw (1) lockwasher (2) and spacer (3).

- Page 64 S301 - Service and Installation - 4/24/18 COIL REPLACEMENT DESCRIPTION Turn off the electrical power supply to the solenoid before The S301 Series Solenoid Valves are 2-way, normally closed, disconnecting the coil lead wires. direct acting, general purpose valves. All stainless steel or brass bodies with synthetic seating and sealing materials make It is not necessary to remove the valve from the pipeline.

- Page 65 SERVICE DISASSEMBLY AND REPAIR KIT INSTALLATION ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person.

- Page 66 REBUILD KIT INSTALLATION AND ASSEMBLY ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person.

- Page 67 S302 - Service and Installation - 4/24/18 DESCRIPTION COIL REPLACEMENT The S302 Series Solenoid Valves are 2-way, normally open, Turn off the electrical power supply to the solenoid before direct acting, general purpose valves. Stainless steel or brass disconnecting the coil lead wires. body with synthetic seating and sealing materials make them suitable for use with a variety of liquids, oils and gases.

- Page 68 SERVICE DISASSEMBLY AND REPAIR KIT INSTALLATION ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person.

- Page 75 S311 - Service and Installation - 4/24/18 DESCRIPTION COIL REPLACEMENT The S311 Series Solenoid Valves are 2-way, normally closed, Turn off the electrical power supply to the solenoid before direct acting, general purpose valves. All stainless steel or disconnecting the coil lead wires. brass bodies with synthetic seating and sealing materials make them suitable for use with a variety of liquids, oils and gases.

- Page 76 SERVICE DISASSEMBLY AND REPAIR KIT INSTALLATION ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person.

- Page 77 REBUILD KIT INSTALLATION AND ASSEMBLY ________________________________________________ WARNING Disassembly, reassembly or internal adjustment without factory test may result in hazardous condition. If valve does not operate properly after following the INSTALLATION and MAINTENANCE instructions, complete valve must be replaced by a trained and experienced service-person.

-

Page 82: Operating Temperatures

DESCRIPTION S336 Series are 3-way direct acting solenoid valves, with all three pipe connections marked 1,2 and 3 located in the forged brass or stainless steel body. Mounting bracket is standard on all stainless steel valve body sizes. Valves are designed for use with flow media such as air, hydraulic oil, water, and No. - Page 83 Connect pipe to valve with flow in accordance with the Check valve on a routine basis, preferably monthly port designation on valve body. Apply thread sealant to or more often to assure that unit opens and closes as male pipe threads only. Applying sealant to valve threads required.

-

Page 84: Disassembly And Reassembly

DISASSEMBLY AND REASSEMBLY 7. Remove plunger spring plunger assembly and “O” Turn off flow medium and electrical power supply to ring. valve. 8. Unscrew valve cap or manual override assembly (in the case of valve with manual override option) from Standard and Open Frame Models (See Fig. - Page 85 Fig. 2 Exploded View of Typical S33 Standard and Open Frame Models Fig. 3 Exploded View of Typical S33 Explosion Proof Model...

-

Page 97: Installation

Installation: 1. Clear all lines of foreign matter. 2. Xtreme valves can be mounted in any position. However, installation with the coil in an upright position is preferred. 3. Thread sealant or Teflon tape should be used sparingly and applied only to the threads of the male fitting. - Page 99 Installation: 1. Clear all lines of foreign matter. 2. Xtreme valves can be mounted in any position. However, installation with the coil in an upright position is preferred. 3. Thread sealant or Teflon tape should be used sparingly and applied only to the threads of the male fitting.

- Page 101 Installation: 1. Clear all lines of foreign matter. 2. Xtreme valves can be mounted in any position. However, installation with the coil in an upright position is preferred. 3. Thread sealant or Teflon tape should be used sparingly and applied only to the threads of the male fitting.

- Page 103 Installation: 1. Clear all lines of foreign matter. 2. Xtreme valves can be mounted in any position. However, installation with the coil in an upright position is preferred. 3. Thread sealant or Teflon tape should be used sparingly and applied only to the threads of the male fitting.

- Page 104 Installation 1. Unscrew Top Cap assembly (1) one full turn. 2. Rotate Coil Jacket (6) to properly align the conduit hub. 3. Re-tighten Top Cap (1) after completing the conduit connection. Removal and Reassembly 1. Remove Top Cap assembly (1), and Top Cap “O”...

Need help?

Do you have a question about the GC Valves H211 Series and is the answer not in the manual?

Questions and answers