Advertisement

Quick Links

Quick installation guide for MW-10/MW-11

Read this instruction carefully to use the device correctly. For detailed information, please refer to the instruction

manual for the radar level gauge itself, "Non-contact Radar Level Gauge MW-10 MW-11 User's Guide".

(document number: KF24-001*)

1. Site Check

Please install level gauge avoiding any obstructions in

the following beam area, which may any cause of

disturbance reflection.

Model 10m

Distance

Model 15m

[m]

Model 30m

Beam angle=

5

10

15

30

50

100

It is recommended not to install the obstructions in an

area of twice beam angle for more stable

measurements.

2. Installation Tips

For stable measurement, please keep the mounting

parallel to the level plane to get better signal strength to

liquid surface.

The following cases will affect measurement

performance:

(1) The full performance is not achieved in the level

gauge installed incorrectly.

(2) Obstructions in the beam area will reduce reflection

signal and decrease and narrow the measurable

range.

(3) Deposit buildup on the antenna, foaming on liquid

surfaces may affect measuring range and

performance.

(4) Compared to calm liquid surfaces, measuring

ranges of turbulent surfaces are reduced due to

poorer reflection.

◆ Electrical Rating

MW-10

Operating voltage

Max. Current

Cable requirement

Cable entry

MW-11

Operating voltage

Cable requirement

Cable entry

Document No. KF24-003

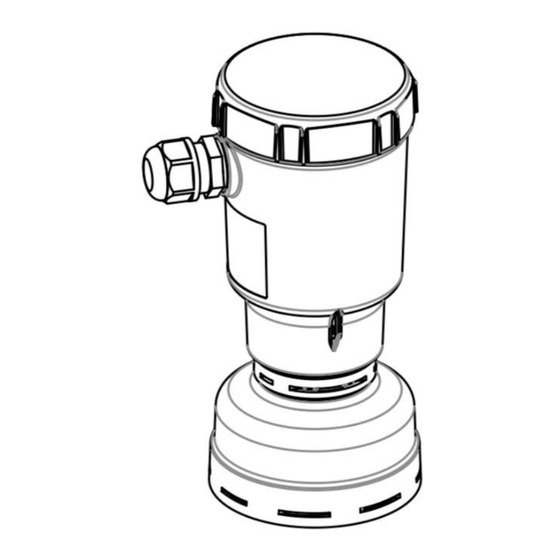

Thank you very much for purchasing TOKYO KEIKI's Non-Contacting Radar Level

Gauge MW-10/MW-11. This instruction provides summarized the precautions for

using the Non-Contacting Radar Level Gauge MW-10/MW-11 safely and correctly.

Beam area [m]

Model 50m

Model 100m

Beam angle=

6°

3°

0.52

0.26

1.05

0.52

1.57

0.79

3.14

1.57

-

2.62

-

5.24

DC12...36V

22 mA

Twisted pair 2 core shielded cable

(0.2 to 2.5mm-sq / AWG 24 to 14)

M20 x 1.5

DC10.5...36V

Twisted pair 4 core shielded cable

(0.2 to 2.5mm-sq / AWG 24 to 14)

M20 x 1.5

3. Mechanical Installation

(If bracket used then follow the below steps)

Hexagon wrench (5mm) is required to assemble the

mounting bracket.

(1) Fit the recessed part in the mounting bracket to the

projected part in the case.

(2) Tighten up the bolt with hexagon wrench. Two bolts

are boxed together with the mounting bracket.

(3) Install at customer's preferred location using 4 holes

of the bracket for installation.

NOTE: For stable measurements, keep the mounting

bracket parallel to the level plane to get better

signal strength to liquid surface.

NOTE: The mounting bracket assembly for 50m/100m

model is the same as for 10m/15m/30m model.

◆ Fig.1 Attaching Mounting bracket

(1)

Copyright 2024 by TOKYO KEIKI INC. All rights reserved.

Advertisement

Summary of Contents for Tokyo Keiki MW-10

- Page 1 Quick installation guide for MW-10/MW-11 Read this instruction carefully to use the device correctly. For detailed information, please refer to the instruction manual for the radar level gauge itself, "Non-contact Radar Level Gauge MW-10 MW-11 User's Guide". (document number: KF24-001*) 1.

- Page 2 ◆ Fig.6 System configuration (MW-11) terminal block with earth symbol as is necessary. (5) Cable gland should be tightened properly. (6) Tighten the terminal cover. ◆ Fig.2 Cable terminal block and wiring (MW-10) Terminal block MWConfig TKGauge Terminal block lever...

Need help?

Do you have a question about the MW-10 and is the answer not in the manual?

Questions and answers