Advertisement

Quick Links

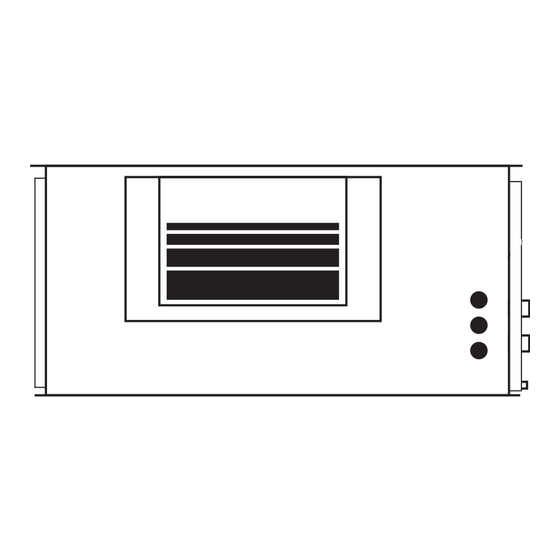

IMD 95

Ducted

Fan Coil Unit

Dimensions (mm)

Not to Scale

Fig. 1

SPRING MTG CTRS

HANGING CENTRES

85

595

OPTIONAL

SPRING MTG

CENTRES

530

HANGING

CENTRES

145

400

MOTOR DRIVER

ACCESS PANEL

360 OA

770

OVERALL

Fig. 2 Spring Mounting

RECOMMENDED

MOUNTING

SYSTEM

(OPTIONAL

EXTRA)

Fig. 4

FLEXIBLE

TUBE

70–100mm

UNIT

100 mm

APPROX.

'U' TRAP

690

650

OPTIONAL

590

FILTER BOX WITH

FILTER ACCESS

EACH SIDE

WATER

CONNECTIONS:

25 BSP MALE

(HEATING

15 BSP MALE)

MOUNTING

SLOTS 20 x 9

ELECTRICAL

15

CONDUIT HOLES

225

120

Fig. 3 Solid Mounting

VENT PIPE

100 mm

FOR LONG

APPROX.

CONDENSATE

DRAIN RUNS

50 mm

MINIMUM

OPEN

DRAIN

PROJECTION

Net Weight 45 kg

(excluding water)

FAN ACCESS VIA

REMOVEABLE BASE

& DRAIN TRAY,

OR VIA TOP PANEL

ELECTRICAL

135

ACCESS PANEL

60

60

15

285

OUT

IN

60

DRAIN 19 OD

630 OA

MOUNTING ROD

MOUNTING FLANGE

TIGHTEN

LOCKNUTS

FOR

STRENGTH

Condensate Drain

MINIMUM

SLOPE

20 mm PER m

(1 IN 50)

Installation &

Maintenance

GENERAL

The IMD ducted fan coil units must be

installed in accordance with all national and

local safety codes.

Options

1. Filter Box

2. Spring Mounting Kit

3. Electric Elements c/w fan run-on timer

4. Flexible water hoses

FILTER BOX (Option)

The Filter Box is installed by unscrewing

the return air spigot and replacing it with

the Filter Box's filter-integrated spigot. The

filter may be accessed from either side of

this spigot. This new spigot has a depth of

135 mm, instead of 60 mm.

ELECTRIC HEAT (Factory Fitted Option)

Refer to wiring diagram for size of elements

supplied. A fan run-on timer for rapid heat

dissipation is included with this option.

A 24 hour power supply is essential for this

timer to function correctly.

INSTALLATION

Positioning & Mounting

When determining the position of the fan coil

unit, allow adequate space around the unit

to facilitate water pipe/hose connections,

future servicing and maintenance. Ensure

there is enough working space in front of

the electrical access panel. Allow adequate

clearance for the filter to be withdrawn to

its full length from either end of the unit.

Provision should be made for access to

remove the unit from the ceiling if the need

arises.

If low noise is a critical factor in the

installation, refer to Figure 5 for noise

isolation recommendations.

It is recommended that the unit be mounted

using the spring mounting system, supplied

as an optional extra (Fig.2). This system

minimises transfer of vibration into the

building structure.

If a more rigid installation can be tolerated,

then suspend the unit from four threaded

rods (not supplied) and use locknuts (not

supplied), as shown in Figure 3.

The unit has a built-in sloping drain tray,

therefore mount it level.

When finally positioned, tighten the lock

nuts on the mounting rods from above and

below the mounting flange to give a firm

installation (see Fig. 3).

Condensate Drain

The condensate drain should be trapped

outside the unit cabinet. The trap should

have a vertical height of at least 50 mm.

The drain should have a slope of at least

1 in 50 and must not be piped to a level

above the unit drain tray. (Refer Fig.4).

Advertisement

Summary of Contents for TemperZone IMD 95

- Page 1 IMD 95 Ducted Installation & Fan Coil Unit Maintenance Dimensions (mm) GENERAL PROJECTION The IMD ducted fan coil units must be Not to Scale installed in accordance with all national and local safety codes. Fig. 1 Options SPRING MTG CTRS 1.

- Page 2 Use flexible tube to connect the unit's drain MAINTENANCE UNITS WITH ELECTRIC HEAT A 24 hour power supply is required to stub to the external drain pipe. Weekly For First Four Weeks power the fan run-on timer. Recommended 1. Check air filter (if fitted); vacuum clean as external fuse size for a unit factory fitted with necessary.

- Page 3 A1 B1 A2 15 16 18...

- Page 4 © temperzone limited 2022 10/22 Pamphlet No. 2525...

Need help?

Do you have a question about the IMD 95 and is the answer not in the manual?

Questions and answers