Table of Contents

Summary of Contents for HOLLAND LIFT B-195DL25-4WD

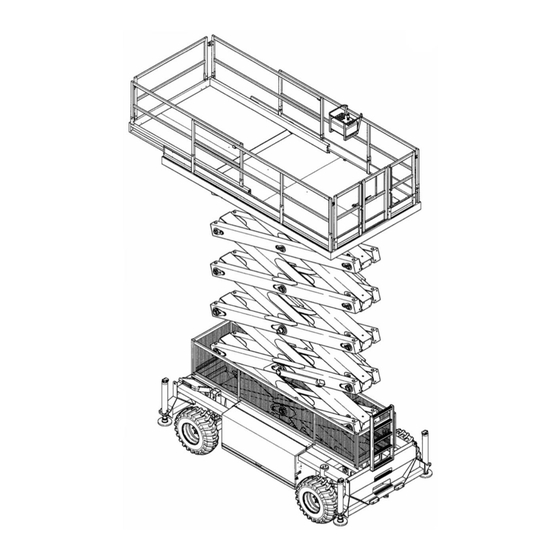

- Page 1 B-195DL25-4WD-P-N Rev. B (ENG) OPERATION MANUAL COMBISTAR SCISSOR LIFT MODEL B-195DL25-4WD/P/N HOLLAND LIFT INTERNATIONAL B.V. Anodeweg 1, NL-1627 LJ HOORN Tel.: +31-(0)229-285555, Fax.: +31-(0)229-285550 www.hollandlift.com Page 1 09-3-2007...

- Page 2 B-195DL25-4WD-P-N Rev. B (ENG) © 2006 HOLLAND LIFT INTERNATIONAL B.V., Hoorn, The Netherlands Warning: Nothing of this manual may be copied, photocopied etc. without written permission of HOLLAND LIFT INTERNATIONAL B.V. Page 2 09-3-2007...

-

Page 3: Table Of Contents

WARNINGS AND SYMBOLS ....................7 TECHNICAL DATA ........................8 STANDARD EXECUTION ..................... 8 OPTIONS..........................8 THE MANUFACTURER DECAL ................... 8 TECHNICAL DATA MODEL B-195DL25-4WD/P/N.............. 9 SAFETY PRECAUTIONS AND PROVISIONS ............... 10 IMPORTANT: USE ONLY AS DESIGNATED ..............10 APPLICATIONS........................10 BASIC PROVISIONS ......................11 CHOICE OF PERSONNEL AND QUALIFICATION ............ - Page 4 B-195DL25-4WD-P-N Rev. B (ENG) 4.2.14 Platform during transportation ................19 4.2.15 Oscillating axle......................20 4.2.16 Stabilisers ........................ 20 OTHER COMPONENTS ....................... 21 4.3.1 Diesel engine......................21 4.3.2 Valve cabinet......................21 OPERATION ..........................22 GENERAL..........................22 POSITION OF THE CONTROLS................... 22 CONTROLS...........................

-

Page 5: List Of Illustrations

B-195DL25-4WD-P-N Rev. B (ENG) LIST OF ILLUSTRATIONS Fig. Description Page . 1 M ...................... 8 ANUFACTURER DECAL . 2 T B-195DL25-4WD/P/N ....................9 . 3 P ....................15 OSITION SAFETY DEVICES . 4 C ........................16 ONTROL BOX . 5 T ........................ -

Page 6: General Information

USE OF THIS MANUAL This manual is a guideline for a safe and efficient use, maintenance and repair of minor problems of the HOLLAND LIFT scissor lift, model B-195DL25-4WD/P-N. Persons who are performing maintenance on these machines must read, understand and obey the contents of this manual. -

Page 7: Modifications

For this reason the contents of this manual are subject to change without prior notice by HOLLAND LIFT INTERNATIONAL B.V. LIABILITY HOLLAND LIFT INTERNATIONAL B.V. takes no responsibility for: • damages resulting from the use of the scissor lift; • printing errors in this manual and its consequences. -

Page 8: Technical Data

B-195DL25-4WD-P-N Rev. B (ENG) TECHNICAL DATA STANDARD EXECUTION • Control box with plug-in connection on platform and chassis. • Auxiliary switch on the lower control box for lifting/lowering. • Proportional drive. OPTIONS • 230 VAC connection at the platform. • Rotating beacon in addition to acoustic travel alarm. -

Page 9: Technical Data Model B-195Dl25-4Wd/P/N

B-195DL25-4WD-P-N Rev. B (ENG) TECHNICAL DATA MODEL B-195DL25-4WD/P/N Suitable for indoor use Suitable for outdoor use Max. wind speed 12,5 m/s Working height, approx. 21,54 m Max. platform height, approx. 19,54 m Min. platform height, approx. 2,45 m Platform (retracted) -

Page 10: Safety Precautions And Provisions

0-position on the electric cabinet). APPLICATIONS The scissor lift, type B-195DL25-4WD/P/N, is suitable for both indoor and outdoor use, with an ambient temperature between -15° C and +40° C. The driving surface must be even, level, free of snow & ice and free of obstacles. -

Page 11: Basic Provisions

Modifications of the construction of the machine may only be executed with written permission of HOLLAND LIFT INTERNATIONAL B.V. Parts may only be replaced by parts supplied by HOLLAND LIFT INTERNATIONAL B.V. or parts of equal quality. HOLLAND LIFT INTERNATIONAL B.V. maintains the right to define whether these parts are equal. -

Page 12: Safety Instructions In Different Situations

B-195DL25-4WD-P-N Rev. B (ENG) SAFETY INSTRUCTIONS IN DIFFERENT SITUATIONS 3.5.1 Normal use Avoid any operation that can compromise safety. Use and operate the machine only when all safety provisions have been checked and are functioning. Do not exceed the maximum work-load. -

Page 13: Safety During Maintenance

B-195DL25-4WD-P-N Rev. B (ENG) 3.5.2 Safety during maintenance Perform the maintenance and repair only when the machine is standing on a level and firm surface. Use wedges to avoid the machine to roll away. When the machine is switched of during maintenance or repair, precautions must be taken to avoid unintended use of the machine. -

Page 14: Safety During Transportation

B-195DL25-4WD-P-N Rev. B (ENG) Hydraulic system 1. Hydraulic oil can become hot during operation. Avoid skin-contact with the hot oil! 2. Hydraulic lines, which are under pressure, should not be touched! 3. Pressurised hydraulic oil can perforate the skin and cause fatal injuries Do not try to find leakage’s manually! -

Page 15: Description Of The Scissor Lift

B-195DL25-4WD-P-N Rev. B (ENG) DESCRIPTION OF THE SCISSOR LIFT POSITION OF THE SAFETY DEVICES Fig. 3 Position safety devices Emergency stop Tilt alarm limit switch Travel alarm, acoustic Safety device lowering Travel alarm, visual Safety props Limit switch (high speed) -

Page 16: Safety Devices

B-195DL25-4WD-P-N Rev. B (ENG) SAFETY DEVICES 4.2.1 Emergency stop A red emergency stop button is installed on the control box (Fig. 4-1). Pushing this button will switch off all functions. Turning the button will switch on all functions with a delay of 2 seconds. The diesel engine can be started again. -

Page 17: Tilt Alarm

B-195DL25-4WD-P-N Rev. B (ENG) 4.2.6 Tilt alarm When exceeding the maximum grade/slope angle, at a platform height above 4 meter, a warning signal sounds and all functions will be switched off, with exception of the lowering function of the platform. -

Page 18: Emergency Lowering Device

B-195DL25-4WD-P-N Rev. B (ENG) 4.2.9 Emergency lowering device In case of an emergency the platform can be lowered by opening the emergency-lowering valve, which is mounted on the lift cylinder. Pulling the knob on the valve can activate it. First the extended platform has to be retracted with the hand pump (Fig. 8) before emergency lowering. -

Page 19: Safety Prop

B-195DL25-4WD-P-N Rev. B (ENG) 4.2.11 Safety prop Operations on or between the scissor arms are only allowed when the safety prop (Fig. 10) secures the scissor mechanism. During use of the safety prop, the scissor lift must not have a load on the platform. -

Page 20: Oscillating Axle

B-195DL25-4WD-P-N Rev. B (ENG) 4.2.15 Oscillating axle The oscillating axle allows for positive grip in rough terrain with a four-wheel drive scissor lift. When the oscillating axle is not horizontal and the platform height is above 4 meter, the oscillatingaxle will be blocked and the driving function will be switched off automatically. -

Page 21: Other Components

B-195DL25-4WD-P-N Rev. B (ENG) OTHER COMPONENTS 4.3.1 Diesel engine Fig. 13 Diesel engine Hydraulic tank Diesel engine Return filter Diesel tank Pumps 4.3.2 Valve cabinet Fig. 14 Diesel engine and hydraulic compartment Tilt alarm Limit switches Electrical system Hand pump... -

Page 22: Operation

B-195DL25-4WD-P-N Rev. B (ENG) OPERATION GENERAL When operating the scissor lift the safety precautions should be observed first (see chapter 3). POSITION OF THE CONTROLS Fig. 15 Overview controls Control box Auxiliary switch lifting/lowering Main switch Page 22 09-3-2007... -

Page 23: Controls

B-195DL25-4WD-P-N Rev. B (ENG) CONTROLS 5.3.1 Control box All functions of the machine are operated with a control box, which is mounted on the platform. Operation is allowed by persons located on the platform only. The upper side of the control box consists of a panel with toggle switches and related symbols. -

Page 24: Auxiliary Switch Lifting/Lowering

B-195DL25-4WD-P-N Rev. B (ENG) 5.3.3 Auxiliary switch lifting/lowering On the lower control box in the hydraulic compartment an auxiliary switch (Fig. 18-1) with an automatic zero-position is mounted for lifting and lowering. This switch can be used for maintenance and in case of an emergency. -

Page 25: Operation

B-195DL25-4WD-P-N Rev. B (ENG) OPERATION 5.4.1 Preparations for use Check: • correct operation of all functions; • correct operation of all safety devices; • the scissor lift on visual damages (don’t forget the tires); • the hydraulic system on leakages;... -

Page 26: Operating The Stabilisers

B-195DL25-4WD-P-N Rev. B (ENG) 5.4.3 Operating the stabilisers • Selection switch 10 (Fig. 16-10) should be set to extend stabilisers. • Then operate switch 8 (Fig. 16-8) for as long as it takes to secure contact for all four stabilisers. This will be indicated by the continuous burning of lamp 12 (Fig. 16-12). -

Page 27: Towing And Transportation

B-195DL25-4WD-P-N Rev. B (ENG) TOWING AND TRANSPORTATION In full-stop position of the machine the brakes are activated. When towing the scissor lift, the brakes must be released. 5.5.1 Release of the brakes The scissor lift is equipped with 4 gear boxes with integrated laminated brakes (Fig. -

Page 28: Transportation

• When the scissor lift is lifted on the transportation vehicle by crane, the pull eyes on each corner of the machine can be used. HOLLAND LIFT INTERNATIONAL B.V. does not advise lifting its equipment without a special lifting rectangular. Contact HOLLAND LIFT INTERNATIONAL B.V. -

Page 29: Maintenance

HOLLAND LIFT INTERNATIONAL B.V. When our maintenance protocol is not applied all forms of guarantee and responsibility will lapse. -

Page 30: Lubrication Points

B-195DL25-4WD-P-N Rev. B (ENG) 6.1.2 Lubrication points All lubrication points have to be greased monthly with Teflon based grease (Art.code: VETPATROON). Fig. 23 Lubrication points Before lubrication the safety guard (on the side of the grease nipples) has to be removed. This safety guard has to be remounted before the machine will be operated again. -

Page 31: Scheduled Maintenance

B-195DL25-4WD-P-N Rev. B (ENG) SCHEDULED MAINTENANCE For the maintenance of the diesel engine, please refer to the Hatz-manual. 6.2.1 Daily • Check on leakages in the hydraulic system. • Check the oil level of the diesel engine. • Check the proper operation of all safety devices (see 4.1). -

Page 32: Yearly

In case of major modifications and repairs that affect the stability strength and performance of the aerial platform, the scissor lift should again be inspected and tested by HOLLAND LIFT INTERNATIONAL B.V.. All major repairs should be mentioned in the scissor lift logbook. If this is not done, the Declaration of Conformity shall become invalid. -

Page 33: Extreme Conditions

B-195DL25-4WD-P-N Rev. B (ENG) 6.2.7 Extreme conditions • At extreme exposure to dust, algae, bacteria, salt deposit, moisture etc. the maintenance frequency has to be increased accordingly. 6.2.8 Storage • When the scissor lift will not be used for more than 10 days, the batteries should be checked (charge, water, etc.). -

Page 34: Markings And Decals

B-195DL25-4WD-P-N Rev. B (ENG) 6.2.10 Markings and decals Fig. 24 Markings and decals Reflexfoil "Main switch" Max. load capacity "Hydro-oil" Model indication "Diesel" Use of safety prop "Lowering with not extended platform only" "Max. 2 persons" Lubrication advice "WARNING ..locked"... -

Page 35: Bolt Torque Specifications

B-195DL25-4WD-P-N Rev. B (ENG) BOLT TORQUE SPECIFICATIONS Track rod to wheel support 41 Nm Steering cylinder to track rod 41 Nm Steering cylinder to chassis 60 Nm Rear axle to chassis 390 Nm Wheel nuts 250 Nm Gear box to wheel support... -

Page 36: Trouble Shooting

B-195DL25-4WD-P-N Rev. B (ENG) TROUBLE SHOOTING This chapter handles some errors with the possible cause and solution. Error Possible cause Solution Scissor lift does not Main switch not activated. Turn on main switch. function. Emergency stop button on control Release emergency stop button. -

Page 37: Disposal Of The Scissor Lift

B-195DL25-4WD-P-N Rev. B (ENG) DISPOSAL OF THE SCISSOR LIFT GENERAL When the scissor lift will be disposed of, it has to be done in an environmentally friendly way. Some options are: • Trade in when purchasing a new scissor lift. -

Page 38: Index

B-195DL25-4WD-P-N Rev. B (ENG) INDEX Page Auxiliary switch ............................. 21; 22; 24 Control box................................22; 23 Diesel engine ................................21 Diesel tank ...................................21 Disposal of the scissor lift............................35 Driving speed.................................9 Emergency lowering device ............................18 Emergency stop ............................15; 16; 23; 25 Emergency stop button ............................23; 25 Exhaust pipe ................................13... - Page 39 B-195DL25-4WD-P-N Rev. B (ENG) Safety guard................................15; 19 Safety props .................................15 Steering, right/left................................23 Symbols ..................................7 Thunderstorm ................................13 Tilt alarm ................................ 15; 17; 21 Transportation................................9; 27 Travel alarm, acoustic............................15; 16 Travel alarm, visual ...............................15; 16 Turning radius ................................9 Valves ..................................15; 21 Warning ...................................2; 13 Werkhoogte ...................................9...

Need help?

Do you have a question about the B-195DL25-4WD and is the answer not in the manual?

Questions and answers