Advertisement

Quick Links

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

Visit the Viking website for the latest edition of this technical data page www.vikinggroupinc.com

1. DESCRIPTION

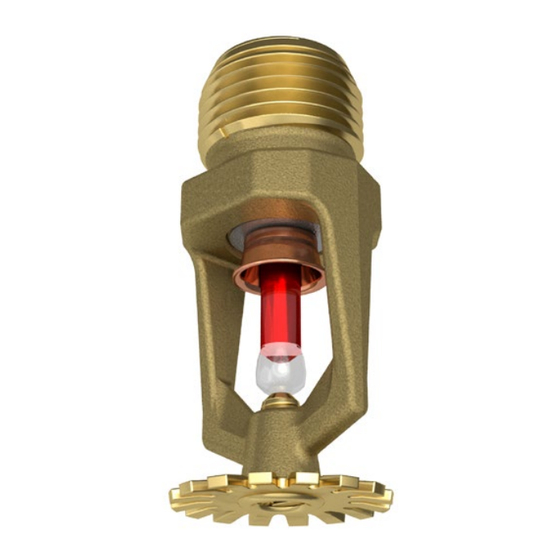

The Viking Micromatic® Standard Response Pendent VK102 Sprinkler is a small, thermosensitive,

glass-bulb spray sprinkler available in several different finishes and temperature ratings to meet design

requirements. The special Polyester, and Electroless Nickel PTFE (ENT) coatings can be used in

decorative applications where colors are desired. In addition, these coatings have been investigated

for installation in corrosive environments and are listed/approved as indicated in the Approval

Charts.

Viking standard response sprinklers may be ordered and/or used as open sprinklers (glass bulb and

pip cap assembly removed) on deluge systems. Refer to Ordering Instructions.

2. LISTINGS AND APPROVALS

cULus Listed: Category VNIV

FM Approved: Classes 2001, 2002, 2015, 2017, 2043

VdS Approved: Certificate G414006 & G414004

LPCB Approved

CE: Standard EN 12259-1, DOP_Sprinklers_LPCB_5-2-19 & DOP_VK102WAX_2-12-19

MED Certified: Standard EN 12259-1, EC-certificate 0832-MED-1003

China Approval: Approved according to China GB standard.

UKCA Approved: Standard EN 12259-1; Certificate Number 0832-UKCA-CPR-S5029; UKCA DOC_S5029; 2021

NOTE:

Other International approval certificates are available upon request.

Refer to Approval Charts and Design Criteria for listing and approval requirements that must be followed.

3. TECHNICAL DATA

Specifications:

Minimum Operating Pressure: 7 psi (0.5 bar)*

Maximum Working Pressure: 175 psi (12 bar) wwp

Factory tested hydrostatically to 500 psi (34.5 bar)

Thread size: 1/2" NPT, 15 mm BSPT

Nominal K-factor: 5.6 U.S. (80.6 metric**)

Glass-bulb fluid temperature rated to -65 °F (-55 °C)

Overall Length: 2-1/4" (57 mm)

* cULus Listing, FM Approval, and NFPA 13 installs require a minimum of 7 psi (0.5 bar). The minimum operating pressure for LPCB and CE Approvals

ONLY is 5 psi (0.35 bar).

** Metric K-factor measurement shown is in Bar. When pressure is measured in kPa, divide the metric K-factor shown by 10.0.

Material Standards:

Frame Casting: Brass UNS-C84400 or QM Brass

Deflector: Phosphor Bronze UNS-C51000 (Not for FM Approval) or Copper UNS-C19500

Bulb: Glass, nominal 5 mm diameter

Belleville Spring Sealing Assembly: Nickel Alloy, coated on both sides with PTFE Tape

Screw: Brass UNS-C36000

Pip Cap and Insert Assembly: Copper UNS-C11000 and Stainless Steel UNS-S30400

For Polyester Coated Sprinklers: Belleville Spring-Exposed

For ENT coated Sprinklers: Belleville Spring - Exposed, Screw and Pipcap - ENT plated.

Ordering Information: Refer to Table 1

4. INSTALLATION

Refer to appropriate NFPA Installation Standards.

5. OPERATION

During fire conditions, the heat-sensitive liquid in the glass bulb expands, causing the glass to shatter, releasing the pip cap and

sealing spring assembly. Water flowing through the sprinkler orifice strikes the sprinkler deflector, forming a uniform spray pattern

to extinguish or control the fire.

Form No. F_031414

Rev 02

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

November 2023

MICROMATIC

STANDARD

®

RESPONSE PENDENT

SPRINKLER VK102 (K5.6)

Replaces Form No. F_031414 Rev 01

(added UKCA.)

Page 1 of 8

Advertisement

Summary of Contents for Viking MICROMATIC VK102

- Page 1 Approval Charts. Viking standard response sprinklers may be ordered and/or used as open sprinklers (glass bulb and pip cap assembly removed) on deluge systems. Refer to Ordering Instructions.

- Page 2 Standard Response Upright Sprinkler VK100 is available through a network of domestic and international ® distributors. See The Viking Corporation web site for the closest distributor or contact The Viking Corporation. 8. GUARANTEE For details of warranty, refer to Viking’s current list price schedule or contact Viking directly.

- Page 3 B. Standard Wrench for Wax Coated Sprinklers: Part No. 10896W/B C. Socket Wrench for Recessed Pendent Sprinklers: Part No. 13655W/B (A 1/2” ratchet is required, not available from Viking) D. Socket Wrench for Wax Coated Sprinklers: Part No. 13577W/B (A 1/2” ratchet is required, not available from Viking) E.

- Page 4 X = Recessed with the Viking Model E-1, E-2, or E-3 Recessed Escutcheon Y = Standard surface-mounted escutcheon or recessed with the Viking Model E-1, E-2, or E-3 Recessed Escutcheon Z = Standard surface-mounted escutcheon or recessed with the Viking Model E-1 Recessed Escutcheon Footnotes Base part number is shown.

- Page 5 4 = ENT 5 = Chrome Approved Escutcheon Codes Y = Standard surface-mounted escutcheon or recessed with the Viking Model E-1, E-2, or E-3 Recessed Escutcheon Z = Standard surface-mounted escutcheon or recessed with the Viking Model E-1 Recessed Escutcheon Footnotes Base part number is shown.

- Page 6 No. F_080614 for general care, installation, and maintenance information. Viking sprinklers are to be installed in accordance with the latest edition of Viking technical data, the appropriate standards of NFPA, FM Global, LPCB, APSAD, VdS or other similar organizations, and also with the provisions of governmental codes, ordinances, and standards, whenever applicable.

- Page 7 SPRINKLER VK102 (K5.6) The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058 Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com Visit the Viking website for the latest edition of this technical data page www.vikinggroupinc.com STANDARD FINISHES 13655W/B*...

-

Page 8: Technical Data

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058 Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com Visit the Viking website for the latest edition of this technical data page www.vikinggroupinc.com Ceiling Opening Size: 2-5/16” (59 mm) minimum 2-1/2”... - Page 9 Refer to the appropriate technical data page and NFPA standards for complete care, handling, installation, and maintenance instructions. For additional product and system information Viking data pages and installation instructions are available on the Viking Web site at www.vikinggroupinc.com.

- Page 10 * Refer to the appropriate current technical data pages for complete care, handling, and installation instructions. Data pages are included with each shipment from Viking or Viking distributors. They can also be found on the Web site at www. vikinggroupinc.com.

- Page 11 • while ceiling finish work is being completed. Use only the designated Viking recessed sprinkler wrench (refer to the appropriate sprinkler data page) to install these sprinklers. NOTE: The protective cap is • temporarily removed during installation and then placed back on the sprinkler for protection until finish work is completed.

- Page 12 Take care not to crack the wax coating on the units. • For touching up the wax coating after installation, wax is available from Viking in bar form. Refer to Table 1 below. The coating MUST be repaired after •...

-

Page 13: Warranty Terms And Conditions

For more information, go to www.P65Warnings.ca.gov 2. WARRANTY TERMS AND CONDITIONS For details of warranty, refer to Viking’s current list price schedule at www.vikinggroupinc.com or contact Viking directly. New Bulletin Form No. F_111218 18.11.15...

Need help?

Do you have a question about the MICROMATIC VK102 and is the answer not in the manual?

Questions and answers