Table of Contents

Advertisement

Quick Links

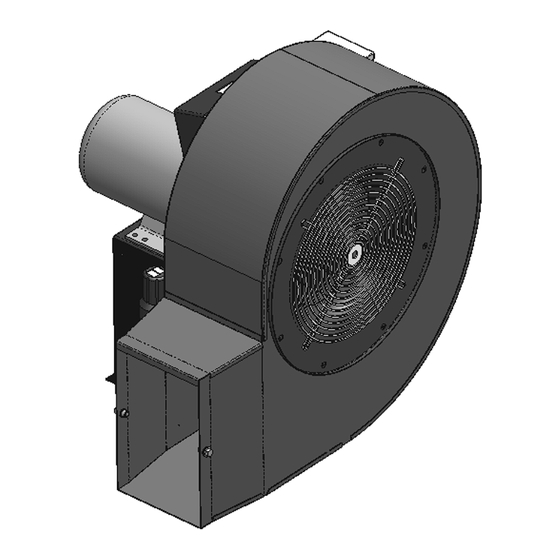

3–15 HP High Speed Centrifugal

Aeration Fan

Centrifugal Fan

Installation, Operation, and Parts Manual

This manual applies to:

GGF-803XX, GGF-805XX, GGF-807XX, GGF-810XX, GGF-815XX

Read this manual before using product. Failure to

follow instructions and safety precautions can

result in serious injury, death, or property

damage. Keep manual for future reference.

INSTALLATION AND WIRING MUST

BE IN ACCORDANCE WITH CEC,

NEC, AND LOCAL ELECTRICAL

CODES

Part Number: CNA-2653 R1

Revised: June 2024

Original Instructions

Advertisement

Table of Contents

Summary of Contents for AGI GGF-803 Series

- Page 1 3–15 HP High Speed Centrifugal Aeration Fan Centrifugal Fan Installation, Operation, and Parts Manual This manual applies to: GGF-803XX, GGF-805XX, GGF-807XX, GGF-810XX, GGF-815XX INSTALLATION AND WIRING MUST BE IN ACCORDANCE WITH CEC, NEC, AND LOCAL ELECTRICAL CODES Read this manual before using product. Failure to Part Number: CNA-2653 R1 follow instructions and safety precautions can Revised: June 2024...

- Page 2 This product has been designed and manufactured to meet general engineering standards. Other local regulations may apply and must be followed by the operator. All personnel must be trained in the correct operational and safety procedures for this product. Use the sign-off sheet below to record initial and periodic reviews of this manual with all personnel.

-

Page 3: Table Of Contents

3–15 HP HIGH SPEED CENTRIFUGAL AERATION FAN – CENTRIFUGAL FAN CONTENTS 1. Introduction ............................5 1.1 General Description........................5 1.2 Serial Number Location......................5 1.3 Intended Use ..........................6 2. Safety............................... 7 2.1 Safety Alert Symbol and Signal Words..................7 2.2 General Safety Information....................... - Page 4 3–15 HP HIGH SPEED CENTRIFUGAL AERATION FAN – CENTRIFUGAL FAN 7.2 Parts List ..........................27 7.2.1 AGI Centrifugal Fan — (GGF)-Replacement Parts ........... 27 7.3 Grain Drying and Aeration Tips....................28 8. Warranty ............................... 31 CNA-2653 R1...

-

Page 5: Introduction

1.1. General Description The AGI 3–15 HP High Speed Centrifugal Aeration Fan is an excellent addition to any new or existing bin. It can allow you to harvest in damp conditions, maintain stored grain in peak condition, and reduce the likelihood of mould growth and insect infestations. -

Page 6: Intended Use

1. INTRODUCTION 3–15 HP HIGH SPEED CENTRIFUGAL AERATION FAN – CENTRIFUGAL FAN 1.3. Intended Use The high speed centrifugal fan is intended for use as listed below and described throughout this manual. Use in any other way is considered contrary to the intended use and is not covered by the warranty. Intended use for the high speed centrifugal fan •... -

Page 7: Safety

3–15 HP HIGH SPEED CENTRIFUGAL AERATION FAN – CENTRIFUGAL FAN 2. SAFETY 2. Safety 2.1. Safety Alert Symbol and Signal Words This safety alert symbol indicates important safety messages in this manual. When you see this symbol, be alert to the possibility of injury or death, carefully read the message that follows, and inform others. -

Page 8: Fan Safety

2. SAFETY 3–15 HP HIGH SPEED CENTRIFUGAL AERATION FAN – CENTRIFUGAL FAN 2.3. Fan Safety • Keep away from fan impeller/blade; high suction can pull a person toward the inlet. Contact with an unguarded impeller/blade will cause severe injury. • Keep the inlet screen in place at all times. •... -

Page 9: Electric Motor Safety

3–15 HP HIGH SPEED CENTRIFUGAL AERATION FAN – CENTRIFUGAL FAN 2. SAFETY 2.5.1 Electric Motor Safety Power Source • Electric motors and controls shall be installed and serviced by a qualified electrician and must meet all local codes and standards. •... -

Page 10: Safety Equipment

2. SAFETY 3–15 HP HIGH SPEED CENTRIFUGAL AERATION FAN – CENTRIFUGAL FAN Work Gloves • Wear work gloves to protect your hands from sharp and rough edges. Steel-Toe Boots • Wear steel-toe boots to protect feet from falling debris. Coveralls •... -

Page 11: Safety Decal Locations And Details

3–15 HP HIGH SPEED CENTRIFUGAL AERATION FAN – CENTRIFUGAL FAN 2. SAFETY 2.8.2 Safety Decal Locations and Details Replicas of the safety decals that are attached to the high speed centrifugal fan and their messages are shown in the figure(s) that follow. Safe operation and use of the high speed centrifugal fan requires that you familiarize yourself with the various safety decals and the areas or particular functions that the decals apply to, as well as the safety precautions that must be taken to avoid serious injury, death, or damage. - Page 12 2. SAFETY 3–15 HP HIGH SPEED CENTRIFUGAL AERATION FAN – CENTRIFUGAL FAN Table 1. Safety Decals Part Number Description 601-1992 NOTICE To prevent possible roof damage, ensure that all roof vents are open and unobstructed. Do not operate aeration fan if it is possible that the roof vents could ice up.

-

Page 13: Electrocution Hazard

3–15 HP HIGH SPEED CENTRIFUGAL AERATION FAN – CENTRIFUGAL FAN 2. SAFETY Table 1 Safety Decals (continued) Part Number Description CNA-1399 WARNING ELECTROCUTION HAZARD Disconnect electrical power at service box before removing cover. 601-1995 WARNING ELECTROCUTION HAZARD To prevent serious injury or death: •... - Page 14 2. SAFETY 3–15 HP HIGH SPEED CENTRIFUGAL AERATION FAN – CENTRIFUGAL FAN Table 1 Safety Decals (continued) Part Number Description 601-4864 1PH WIRING 1PH 60HZ SUPPLY FROM FUSED CIRCUIT BREAKER GREEN SIDE NO 3 POLE SWITCH MOTOR CONTACTOR RED SIDE NC THERMAL OVERLOAD MOTOR...

-

Page 15: Installation

• Verify that the supply voltage is correct. Report missing or damaged parts immediately to ensure that proper credit is received from AGI or your distributor/dealer, and to ensure that any missing parts can be shipped quickly to avoid holding up the installation. -

Page 16: Installing With A Supplemental Heater

3. INSTALLATION 3–15 HP HIGH SPEED CENTRIFUGAL AERATION FAN – CENTRIFUGAL FAN 3.5. Installing with a Supplemental Heater Any type of supplemental heater intended for use with this fan must be installed downstream and may be added if extra conditioning or drying is required. Heating incoming air will damage the fan and its components and is not covered by the warranty. -

Page 17: Mounting The Fan On A Hopper Bottom Bin

3–15 HP HIGH SPEED CENTRIFUGAL AERATION FAN – CENTRIFUGAL FAN 3. INSTALLATION Figure 2. Slab Mounted Fan (Inline Fan) Figure 3. Slab Mounted Fan (Centrifugal Fan) Item Description Transition (Not Load Bearing) Concrete Slab Concrete Anchor Adaptor 3.8. Mounting the Fan on a Hopper Bottom Bin To install the high speed centrifugal fan on a hopper bottom bin: •... -

Page 18: Electrical Connection

3. INSTALLATION 3–15 HP HIGH SPEED CENTRIFUGAL AERATION FAN – CENTRIFUGAL FAN 3.9. Electrical Connection Important Wiring must be completed by a qualified electrician in accordance with all applicable local codes and standards. Provisions of the local electrical code take precedence over the requirements stated in this manual. -

Page 19: Operation

3–15 HP HIGH SPEED CENTRIFUGAL AERATION FAN – CENTRIFUGAL FAN 4. OPERATION 4. Operation For optimal operation, follow these safety precautions, checklists, and instructions. 4.1. Operation Safety • Ensure appropriate safety accessories are installed. Selection and use of safety accessories for the specific installation is the responsibility of the customer. -

Page 20: Roof Vents

4. OPERATION 3–15 HP HIGH SPEED CENTRIFUGAL AERATION FAN – CENTRIFUGAL FAN 4.3. Roof Vents Roof vents should be sized at 1 ft for every 1000 ft /min of air to minimize condensation. Roof vents may become partially or fully blocked with ice in temperatures below freezing with high humidity conditions. -

Page 21: Emergency Stop

3–15 HP HIGH SPEED CENTRIFUGAL AERATION FAN – CENTRIFUGAL FAN 4. OPERATION 4.5. Emergency Stop Foreign Object Obstruction 1. Immediately shut down the high speed centrifugal fan and lock out the power source. 2. Remove the obstruction. 3. Inspect the inlet screen and fan wheel assembly for damage. Repair or replace as required. Excessive Fan Vibration or Noise 1. -

Page 22: Maintenance

• After maintenance is complete, replace all guards, service doors, and/or covers. • Use only genuine AGI replacement parts or equivalent. Use of unauthorized parts will void warranty. If in doubt, contact AGI or your local dealer. 5.2. Maintenance Schedule Follow the Maintenance Schedule below. -

Page 23: Visually Inspect The High Speed Centrifugal Fan

3–15 HP HIGH SPEED CENTRIFUGAL AERATION FAN – CENTRIFUGAL FAN 5. MAINTENANCE 5.3. Visually Inspect the High Speed Centrifugal Fan Check the following during a visual inspection: 1. Ensure all guards are in place and in good working order. 2. Examine the high speed centrifugal fan for damage or unusual wear. Make sure the impeller is clean, undamaged, and rotates freely. -

Page 24: Troubleshooting

If you encounter a problem that is difficult to solve, even after having read through this section, please contact your local dealer or distributor or, go online at https://www.aggrowth.com for additional troubleshooting tips. You may also contact an AGI product specialist at 1–800–565–2840. Before you contact them, please have this manual and the serial number available. - Page 25 Replace or have the impeller rebalanced. Loose motor mounting bolts. Tighten the bolts. Torque to 30 ft/lb. Motor out of balance. Call your dealer/AGI for assistance. Transformer Faulty. Check for voltage (HOV) on outlet side of No power ( 110V) at Monitor terminal transformer, if no power then replace.

-

Page 26: Appendix

7. APPENDIX 3–15 HP HIGH SPEED CENTRIFUGAL AERATION FAN – CENTRIFUGAL FAN 7. Appendix 7.1. Electrical Schematics 1PH WIRING 1PH 60HZ SUPPLY FROM FUSED CIRCUIT BREAKER GREEN SIDE NO 3 POLE SWITCH MOTOR CONTACTOR RED SIDE NC THERMAL OVERLOAD MOTOR WIRES TO BE SUPPLIED SEE MOTOR NAME BY OTHERS... -

Page 27: Parts List

3–15 HP HIGH SPEED CENTRIFUGAL AERATION FAN – CENTRIFUGAL FAN 7. APPENDIX 7.2. Parts List 7.2.1 AGI Centrifugal Fan — (GGF)-Replacement Parts Table 2. High Speed Centrifugal Fan (GGF) Replacement Parts Item Description Part Numbers by Fan HP/Voltage/Phase 7.5 HP... -

Page 28: Grain Drying And Aeration Tips

7. APPENDIX 3–15 HP HIGH SPEED CENTRIFUGAL AERATION FAN – CENTRIFUGAL FAN 7.3. Grain Drying and Aeration Tips • WHAT IS THE DIFFERENCE BETWEEN AERATION, NATURAL AIR DRYING? Aeration is used to control and provide uniform temperature for a grain mass. Natural air drying is generally used for farm bins and is a method of drying grain with or without supplemental heat and is recommended at 1 cfm (13.4 L/s) per bushel of grain. - Page 29 3–15 HP HIGH SPEED CENTRIFUGAL AERATION FAN – CENTRIFUGAL FAN 7. APPENDIX • IF I ADD SUPPLEMENTAL HEAT, CAN I DRY IN HIGH HUMIDITY CONDITIONS? Adding supplemental heat (when available) to the natural air drying process will reduce relative humidity and increase the rate of moisture movement.

- Page 30 7. APPENDIX 3–15 HP HIGH SPEED CENTRIFUGAL AERATION FAN – CENTRIFUGAL FAN 2. You can wait until the outside air temperature falls to 23 to 14°F (-5 to -10°C) and then run the fan for 24– 48 hours to cool the entire grain mass to a storage state (see charts that follow). Once spring conditions return, you can resume the natural air drying process.

-

Page 31: Warranty

8. WARRANTY 8. Warranty Except as expressly provided in this agreement, AGI Nobleford (hereinafter called the Manufacturer) excludes all express or implied warranties, conditions, and obligations of the Manufacturer, whether statutory or otherwise, concerning the quality of the units or their fitness for any purpose. - Page 32 AGI is a leading provider of equipment solutions for agriculture bulk commodities including seed, fertilizer, grain, and feed systems with a growing platform in providing equipment and solutions for food processing facilities. AGI has manufacturing facilities in Canada, the United States, the United Kingdom, Brazil, South Africa, India and Italy and distributes its products globally.

Need help?

Do you have a question about the GGF-803 Series and is the answer not in the manual?

Questions and answers