Table of Contents

Advertisement

Quick Links

Operation Manual

BTB-200 Batching Control

Operation Manual

Software Ver 3.31.77

Patented

U.S. Patent No. 7,980,129, Patent No. 8,581,122, Patent No. 8,853,566

U.S. Patent No. 9,310,243, Patent No. 9,651,413, Patent No. 10,082,421

Canada Patent No. 2,822,294

Korea Patent No. 1900521

1

Version 3.0

Part Number MAN-000008

Advertisement

Table of Contents

Summary of Contents for herdstar BINTRAC BTB-200

- Page 1 Operation Manual BTB-200 Batching Control Operation Manual Software Ver 3.31.77 Patented U.S. Patent No. 7,980,129, Patent No. 8,581,122, Patent No. 8,853,566 U.S. Patent No. 9,310,243, Patent No. 9,651,413, Patent No. 10,082,421 Canada Patent No. 2,822,294 Korea Patent No. 1900521 Version 3.0 Part Number MAN-000008...

-

Page 2: Table Of Contents

Wiring Diagram ................................24 ® HerdStar BinTrac Warranty............................25 is a trademark of HerdStar, LLC. Copyright © 2024 HerdStar, LLC. All rights reserved. Printed in the USA 1400 Madison Avenue Suite 504, Mankato, MN 56001 PH: 507-344-8005 FAX: 507-344-8009 www.herdstar.com Version 3.0... -

Page 3: Overview

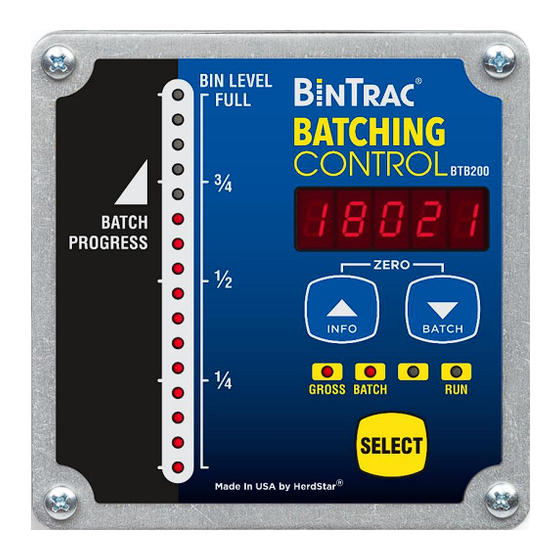

Operation Manual Thank you for purchasing a BinTrac Batching Control from HerdStar, LLC. Overview Your BinTrac Batching Control provides a cost-effective way to automatically monitor bin level and batch a programmed load or unload amount. Components A BinTrac Batching Control system consists of a few basic components: BinTrac Batching Control This is the main unit of the BinTrac Batching Control system. -

Page 4: About This Manual

(gross weight) equals the target batch amount. Feed is then batched from the weigh bin utilizing a low-level bin sensor (not supplied by HerdStar – consult your dealer for options) or other unload method. The system features an auto/manual override feature for the auger via an external switch. - Page 5 Operation Manual Loss-In-Weight (Unload Batch Method) The Loss-In-Weight (Unload Batch Method) allows the user to select the target batch amount of feed required for the day. The BinTrac Batching Control System will enable the hopper or feed line fill system allowing the feed line system to transfer the feed into the house until the required amount of feed has been delivered.

-

Page 6: System Settings

Operation Manual System Settings The SETUP mode is used to configure the different settings and parameters of the BinTrac Batching Control. This section of the manual will explain each option available in the SETUP menu and how to adjust them. For step by step directions on programming and operating your BinTrac Batching Control, see Page 10. -

Page 7: Increment Value

Operation Manual Batch Type Enables you to set the batch option to LoAd or u.LoAd (unload). LoAd is used when you want material batched into a bin. Based on the gross weight of the bin, material is batched into the bin until the batched amount equals the gross amount. - Page 8 Operation Manual Full Value Sets the weight of a full bin in pounds or kilograms. This is for calibration of the LED bar graph level. The value dictates at what net weight the bar graph will display completely full (all 16 LEDs lit). 1.

-

Page 9: Software Version

Operation Manual Minute Sets the current minute Segmented display: Station ID Value Sets the Station ID of the device. When interfacing the device to a Communication Hub (CH100), set this value from 1 to 127. Each BinTrac device must have a unique Station ID when connected to a Communication Hub. 1. -

Page 10: Initial Setup And Operation

Operation Manual Initial Setup and Operation Follow the system wiring diagram (Page 16) to aid in the installation process, including supplied relays and switches. Once installation is completed, the BinTrac Batching Control unit must be programmed as summarized below: System Settings in Setup Mode The SETUP mode is used to configure the one-time system setup settings for the appropriate configuration. - Page 11 Operation Manual 3. Press the SELECT key to enter BATCH TYPE menu and (unload) should be displayed. Use the key to select between (for batching into a bin) or (for batching out of a bin). 4. Press the SELECT key once and will be shown.

- Page 12 Operation Manual Example: A bin weighs 1200 pounds empty. In standard operation mode, simply press and hold on both the keys until displays. This would then set the zero value in the SETUP mode to 1200. Segmented display: 12. Press the SELECT key. The current zero value is shown. If zeroed in standard operation mode, simply record this value for future reference.

-

Page 13: Startup

Operation Manual Startup 1. Inspect the BinTrac system installation on bin and verify legs are evenly lifted and not binding. Confirm clearances shown in the diagram on Page 21. 2. Verify area under bin legs is free and clear of any material. 3. - Page 14 This can be changed so that if the batch is not completed in the 24 hour cycle, it will run the remainder of the original scheduled amount and will reset to the full amount for the next scheduled batch. Please contact HerdStar support to configure this feature. 1. Tap the (BATCH) key until is displayed.

- Page 15 Operation Manual a. For each fill event, the display will cycle through the date, time, and fill amount. For example, a fill of 4000 pounds on January 2 at 5:53pm would display as then then 3. Press the key to view other prior recorded fill events. The LEDs on the Batch Progress meter will change to denote each different entry.

-

Page 16: Wiring Diagram - Single Batching Control

Operation Manual Wiring Diagram – Single Batching Control Version 3.0 Part Number MAN-000008... -

Page 17: Wiring Diagram - Single Batching Control With Remote Display

Operation Manual Wiring Diagram – Single Batching Control with Remote Display Version 3.0 Part Number MAN-000008... -

Page 18: Service

Operation Manual Service Maintenance and Repair Your BinTrac module contains NO USER SERVICEABLE PARTS. If, after troubleshooting, the product stops working for any reason, it must be returned for repair. To keep your BinTrac Batching Control system functioning effectively, ensure that you periodically inspect the weighing system attached to the weigh bin. -

Page 19: Inaccurate Weight Readings

2. Check the Batching Control settings Incorrect weight readings when the system is otherwise functioning normally can be due to incorrect settings. a. Confirm Rated Output – should match the average output recorded on each load cell (3.000 for HerdStar- supplied load cells). - Page 20 These error messages indicate an issue with the internal clock of the Batching Control, likely due to a failure with the internal coin cell battery. 1. Check that the year, month, date, hour, and minute are set correctly (see Pages 8-9). 2. Contact HerdStar for service of the internal coin cell battery. Version 3.0 Part Number MAN-000008...

- Page 21 Operation Manual Load Cell Troubleshooting Procedures The procedures below outline the steps for identifying and locating a defective load cell. Procedure 1 is most commonly used and quickest, although Procedure 2 can be used for better analysis and for determining even loading across all load cells.

-

Page 22: Two Totalized Bins On Bt260 With Btb200 Remote

Operation Manual Appendix A Two Totalized Bins on BT260 with BTB200 Remote In some instances, it may be desirable to combine the weight of 2 bins and send this value to a BinTrac Batching Control. Utilize the wiring diagram on page 24, then take the following steps to put the BT260 into totalizing mode. **If you are having any difficulty setting your BinTrac Indicator for totalizing, please call us at 507-344-8005, Option 2 for assistance. - Page 23 Operation Manual Totalizing Example Two 18 ton bins are being totalized on a BT260 so that their combined weight will be sent to the BTB200 Batching Control. Each bin has 6 legs with 10000 pound load cells. Bin A Bin B Bin C Bin D [SOLID LED]...

-

Page 24: Wiring Diagram

Operation Manual Wiring Diagram Version 3.0 Part Number MAN-000008... -

Page 25: Herdstar Bintrac Warranty

12 months or the term of any extended warranty. In the event of a defect in any Products constituting a breach of the warranty provided herein, HerdStar, LLC will at its option either (i) repair or replace such Product free of charge, or (ii) in lieu of repair or replacement, refund to Buyer the original purchase price less the reasonable value of Buyer’s use of the Products.

Need help?

Do you have a question about the BINTRAC BTB-200 and is the answer not in the manual?

Questions and answers