herdstar BINTRAC Operation Manual

Breeder control

Hide thumbs

Also See for BINTRAC:

- Installation manual (13 pages) ,

- Installation manual (8 pages) ,

- Installation and operation manual (17 pages)

Summary of Contents for herdstar BINTRAC

- Page 1 Operation Manual Breeder Control Operation Manual Patented U.S. Patent No. 7,980,129 and Patents Pending 12/1/2012...

-

Page 2: Table Of Contents

HerdStar, LLC. Copyright © 2011 Herdstar, LLC. All rights reserved. Printed in the USA 1400 Madison Avenue / Suite 504 / Mankato, MN 56001 PH: 507-344-8005 FAX: 507-344-8009 www.herdstar.com BinTrac Breeder Control Operation Manual Ver. 1.01 Rev 1.04 Part # MAN-000008... -

Page 3: Overview

Load Cell Bracket Four or more loadcell brackets allow the BinTrac to accurately measure the material weight in your bins. The Smart Summing Box averages the signals from all brackets to minimize errors that could result from voids (holes) in the material. -

Page 4: System Setup

Selecting Batching Method This procedure will allow you to select the batching method you wish to use. On the BinTrac Indicator, press and hold the SELECT key for approximately 8-10 seconds. The bin level gauge will go blank, and all of the bin selector indicators will illuminate showing their current status. -

Page 5: System Settings

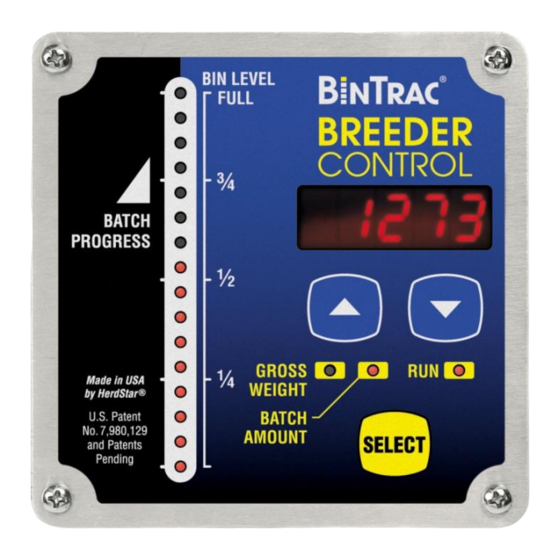

To select an option/parameter to edit in SETUP mode, you must navigate to the option Station ID you wish to edit. Navigate using the keys, and then pressing the SELECT key when you reach the desired option. SS.Ver Figure 1 BinTrac Breeder Control Operation Manual Ver. 1.01 Rev 1.04 Part # MAN-000008... -

Page 6: Options In Setup Mode

SETUP is displayed on the screen, the following LED’s are used to configure the functionality as noted below. Gross Weight – Configures BinTrac Indicator as a Remote Display. A Remote Display is hardwired to a BinTrac Indicator for remotely viewing weight data. Batch Amount – Enable ASCII Serial Communications Command Set. (See Below) BinTrac Monitor or BinTrac Remote Display will transmit weight data based on received commands. -

Page 7: Batch

The average rated output, in millivolt/volt of the load cells. DO NOT CHANGE unless necessary. Every standard load cell has a rated output, specified in mV/V. If using load cells other than the Herdstar load cells, adjust this value appropriately. -

Page 8: Increment Value

This is used to compensate for the empty weight of the bin to give an accurate value for the net weight of the material inside the bin. ** Example: A bin weighs 1,200 lbs. empty. This is then set to the zero value: the BinTrac then calculates the material weight as the total weight less the zero weight value. -

Page 9: Year

Sets the Station ID of the device. For devices interfacing with a Site Console, the Station ID must be set within 100 – 131. When interfacing the device to a Communication Hub (CH100), set this value between 1and 99. Each BinTrac device must have a unique Station ID. -

Page 10: Software Version (Version 1.0 And Higher)

Operation Manual Software Version (Version 1.0 and higher) Displays the BinTrac programmed software version number. This number may be required if technical help is needed. 1. Press the SELECT key to see the software version number. Segmented display: Smart Summing Box Software Version (Version 3.0 and higher) Displays each of the connected Smart Summing Boxes programmed software version number. -

Page 11: Operation

10. To stop a scheduled batch run use the stop and again on the batch amount. The Indicator will then return to display the gross amount in the bin. BinTrac Breeder Control Operation Manual Ver. 1.01 Rev 1.04 Part # MAN-000008... -

Page 12: Paused Batch Run

3. If a FILL event occurs while a batch is running and the weight increases by 50 lbs. or more in the bin, the BinTrac WBBS will pause the batch and switch to FILL batching mode until FILL is completed. -

Page 13: Service

Errors displayed are specific to the selected bin. Error Error -If this is displayed on the screen, the BinTrac is unable to display the current value or the value is outside the displayable range. Verify programmed settings are correct including zero or check for faulty loadcell. - Page 14 In the event of a defect in any Products constituting a breach of the warranty provided herein, Herdstar LLC. will at its option either (i) repair or replace such Product free of charge, or (ii) in lieu of repair or replacement, refund to Buyer the original purchase price less the reasonable value of Buyer’s use of the Products.

Need help?

Do you have a question about the BINTRAC and is the answer not in the manual?

Questions and answers