Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for CLIVET CKN-XHE2i

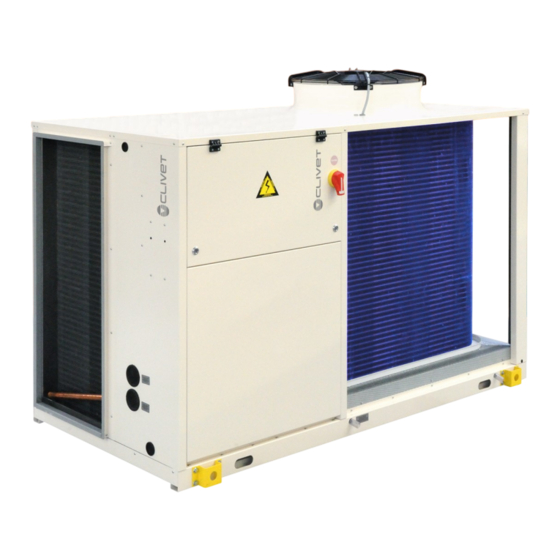

- Page 1 M06K40A18-08 02/2022 R-410A...

- Page 3 I N D E X...

-

Page 4: Installation

1 - S A F E T Y C O N S I D E R A T I O N S Manual The manual provides correct unit installation, use and maintenance. It is advisable to read it carefully so you will save time during operations. -

Page 5: User Training

1 - S A F E T Y C O N S I D E R A T I O N S Modification All unit modifications will end the warranty coverage and the manufacturer responsibility. Breakdown/Malfunction Disable the unit immediately in case of breakdown or malfunction. Contact a certified service agent. -

Page 6: Unit Identification

1 - S A F E T Y C O N S I D E R A T I O N S Unit identification The serial number label is positioned on the unit and allows to indentify all the unit features. The matriculation plate shows the indications foreseen by the standards, in particular: unit type... - Page 7 2 - C O N F I G U R A T I O N S . Air return 2. Electric / hot water heating S. Treated air supply It integrates and/or replaces the direct expansion FA. Outdoor air circuit operation EX.

- Page 8 3 - R E C E P T I O N Saftey Operate in compliance with safety regulations in force. For detailed information (dimensions, weight, technical characteristics etc.) please refer to the TECHNICAL INFORMATION section. Use single protection devices: gloves, glasses etc. Reception You have to check before accepting the delivery: That the unit hasn’t been damaged during transport...

- Page 9 3 - R E C E P T I O N Handling Caution Check that all handling equipment complies with local safety regulations (cran, forklifts, ropes, hooks, etc.). Provide personnel with personal protective equipment suitable for the situation, such as helmet, gloves, accident-prevention shoes, etc.

-

Page 10: Removal Of Packaging

3 - R E C E P T I O N Size 7.1 - 10.1 14.2 1160 1600 Removal of packaging Be careful not to damage the unit. Recycle and dispose of the packaging material in compliance with local regulations. - Page 11 4 - S E L E C T I N G T H E I N S T A L L A T I O N S I T E Positioning Installation must be in accordance with local regulations. If they do not exist, follow EN378 .

- Page 12 4 - S E L E C T I N G T H E I N S T A L L A T I O N S I T E Avoid therefore: obstacles to the airflow exchange difficulties leaves or other foreign bodies that can obstruct the exchange ...

- Page 13 4 - S E L E C T I N G T H E I N S T A L L A T I O N S I T E External air hood CBK, CCK configurations...

- Page 14 4 - S E L E C T I N G T H E I N S T A L L A T I O N S I T E...

- Page 15 The Costumer is responsible for mounting the chimney kit during installation. Based on the specific installation requirements, the length of the chimney can be increased with suitable joints and fittings (not supplied by Clivet). Gas connection Read the gas heating module manual.

- Page 16 4 - S E L E C T I N G T H E I N S T A L L A T I O N S I T E A. Fissare con viti la staffa di sostegno del camino al pannello frontale del modulo gas B.

-

Page 17: Condensate Drain

5 - W A T E R C O N N E C T I O N S Condensate drain The condensate must be disposed in order to avoid damages to people and things. Unit discharge fitting: the connection must not transmit ... - Page 18 5 - W A T E R C O N N E C T I O N S Immersed electrode humidifier Option Connexion humidificateur: 1” F Supply water The humidifier must be supplied with mains water having the following features: pressure between 0.1 and 0.8 Mpa (1 –...

-

Page 19: Heating Coil

5 - W A T E R C O N N E C T I O N S Heating coil Option Max. operating pressure = 10 bar A drain valve B vent valve Provided by the costumer: 1 anti-vibration devices 2 piping supports 3 Shut-off valves... - Page 20 6 - A E R A U L I C C O N N E C T I O N S A E R A U L I C C O N N E C T I O N S The dimensioning and correct execution of the aeraulic connections are fundamental to guarantee good unit operation and adequate level of silence in the room.

-

Page 21: Electrical Data

7 - E L E C T R I C A L C O N N E C T I O N S The characteristics of the electrical lines must be determined by specialized personnel able to design electrical installations; moreover, the lines must be in conformity with regulations in force. The protection devices of the unit power line must be able to stop the presumed short circuit current, whose value must be determined in function of system features. -

Page 22: Power Input

7 - E L E C T R I C A L C O N N E C T I O N S Signals / data lines Do not overpass the maximum power allowed, which varies, according to the type of signal. Lay the cables far from power cables or cables having a different tension and that are able to emit electromagnetic disturbances. - Page 23 7 - E L E C T R I C A L C O N N E C T I O N S Connections performed by costumer...

- Page 24 7 - E L E C T R I C A L C O N N E C T I O N S ON-OFF remote MENU > Assistance setting* > Operation parameter > P05 EnONOFF *Assistance setting: accesso al menu protetto da password Do not perform short On Off cycles Do not use the remote On Off with thermoregulation function.

- Page 25 7 - E L E C T R I C A L C O N N E C T I O N S 1) Use straight head screwdriver to insert in the buckling position in the bottom of wired controller, and spin the screwdriver to take down the back cover.

- Page 26 7 - E L E C T R I C A L C O N N E C T I O N S Avoid the water enter into the wired remote controller, use trap and putty to seal the connectors of wires during wiring installation.

-

Page 27: Preliminary Checks

8 - S T A R T - U P S T A R T - U P The indicated operations must be carried out by qualified technicians and specifically trained on the product. Upon request, the after-sales assistance centres execute start-up. The electric, hydraulic connections and the other work of the system are the responsibility of the installer. -

Page 28: Cooling Circuit

8 - S T A R T - U P Preliminary checks For details refer to the various chapters in the manual. unit ON power supply 1 compressor carter heaters ON from at least 8 hours 2 vacuum voltage measurement 3 phases sequence control 4 shut-off valve refrigerant circuit open (if present) 5 unit ON... -

Page 29: Electric Circuit

8 - S T A R T - U P Electric Circuit Verify that the unit is connected to the ground plant. Check the conductors are tightened as: the vibrations caused by handling and transport might cause these to come loose. Connect the unit by closing the sectioning device, but leave it on OFF. -

Page 30: Remote Controls

8 - S T A R T - U P Standard mode Remote controls Check that the remote controls (ON-OFF etc) are connected and, if necessary, enabled with the respective parameters as indicated in the “electrical connections” section. Fanspeed Check that probes and optional components are connected and enabled with the respective parameters (“electrical connections”... -

Page 31: Eco Mode

8 - S T A R T - U P Eco Mode The air flow supply remains constant at varied heat loads and is shutdown when setpoint is fulfilled. To further increase the energy savings in this condition, it is also possible to set less demanding operation setpoints for the unit in respect to the standard mode. - Page 32 8 - S T A R T - U P The HEAT / COOL mode can be modified: manually through the SA5 contact, from the keypad or P06 EnMode through the BMS digital input SA5 automatically depending on the return temperature ...

- Page 33 8 - S T A R T - U P Variable set point - Manual mode Automatic set point - Automatic mode Fire alarm: configuration It is possible to configure the unit behaviour in presence of alarm signal. Par 11 TypeFireMode MENU >...

-

Page 34: Room Pressure Calibration

8 - S T A R T - U P Room pressure calibration CCK configuration 1 check the doors and windows of the serviced room are closed 2 calibration must be carried out with unit all in recirculation 3 view the status on the display: Pf2 RETURN AIR PRE 4 wait for the pressure value to stabilise and take note of the value 5 to keep the room at neutral pressure, memorise the value of... - Page 35 9 - C O N T R O L MENU To access the various menus of the HOME page. ▲ up, ▼ down, ◄ left, ► right ▲, ▼, ◄ ► To shift the cursor, modify the selection or modify the set value. The parameter can be rapidly modified by pressing it extendedly..

- Page 36 9 - C O N T R O L Mode: indicates, respectively, heat, cool and auto Controller deactivated (off) Remotely controlled controller Appears when the unit is set from the keypad for being controlled from a remote terminal or a remote switch. Return air temperature.

- Page 37 9 - C O N T R O L Lock/unlock To lock/unlock the screen, press UNLOCK for 3 sec. Switch-on/off To switch it on/off, press ON/OFF. Temperature/humidity adjustment Press ◄ ► to adjust the temperature Press ▲▼to select Press◄ ► to adjust the temperature (if the sensor is enabled) Press OK to confirm If no operations are made for more than 10 sec, the system automatically memorises the settings and returns to the home page...

- Page 38 9 - C O N T R O L Settings menu Press ▲▼ to select each menu option. Press OK to access the corresponding sub-menu Press BACK to return to the home page . If ENMode=0 or =2 (in the ASSISTANCE menu), the mode operation is disabled If ENMode=3 (in the ASSISTANCE menu), the mode and eco mode operations are disabled...

- Page 39 9 - C O N T R O L Timer Select TIMER using ◄ ► and press OK. Press ◄ ► to select the value of the password Press ▲ ▼ to enter the value of the password. The password is 123 and cannot be modified. If the password is incorrect, the display will appear as follows: After entering the correct password, the display will appear as follows: Daily timer...

- Page 40 9 - C O N T R O L Press ▲ ▼ to choose timer T1 - T5. Press ON/OFF to enable/disable the selected timer. Press ▲▼ to select each option to be set Press ▲ ▼ to adjust the temperature and start/end time parameters. Press OK to confirm the setting and return to the previous page, or press BACK to delete the setting and return to the previous page .

- Page 41 9 - C O N T R O L Verification of the weekly schedule Select CANCEL TIMER in the TIMER menu Press ◄ ► to select YES. Press OK to cancel all the settings of the daily and weekly timers. AUTOMATIC TEMPERATURE Press ON/OFF to enable/disable the function.

- Page 42 9 - C O N T R O L When ECO RUNNING is set to ON, the set point cannot be modified from the HOME page; if the user attempts to modify it, the following page appears: If YES is selected, the ECO RUNNING function is disabled; if NO is selected, ECO RUNNING is still active .

- Page 43 9 - C O N T R O L Code Description Main board EPROM fault Main board phase error Communication error between the main board and the keypad/controller T2 probe fault Tw probe fault T3 probe fault T1 probe fault T4 probe fault Power phase protection fault Compressor type error...

- Page 44 9 - C O N T R O L KEYPAD SETTINGS Select INTERFACE SETTING To shift the cursor, press ▲ ▼; select ON or OFF To adjust the value, press ◄ ►. To select the language, press ▲ ▼. SERVICE INFORMATION Select SERVICE INFORMATION To shift the cursor, press ▲...

- Page 45 9 - C O N T R O L MODBUS Summary The communication protocol is between the wired controller and the unit, adopt Modbus RTU, wired controller is Master, Unit is Slave. Enabling Menu > Assistance setting > password > operation parameter : 05 EnOnOff = 2 06 EnMode = 2 Communication spec:RS-485:...

- Page 46 9 - C O N T R O L Error code Exception Code) Illegal function code Unsupported function code. illegal data address The address that is sent when query or set, undefined in the online controller. illegal data value The parameters set are illegal, beyond the reasonable range or not the valid parameter for current state of the wired controller.

- Page 47 9 - C O N T R O L Status Register Register content Note number Host address PCB swithches setting Encoder setting 7 = size 7.1; 11 = size 10.1; 18 = size 14.2 Operation mode 8=OFF; 0=Stanby; 1=Cooling mode; 2=Heating mode 1 = ON 0 = OFF BIT0 = Unit running...

- Page 48 9 - C O N T R O L Status Register Register content Note number TP2 - Discharge temperature C2 -25 °C ~ 70 °C (Only size 14.2) TF1 - Inverter module 1 temperature 0 °C ~ 140 °C TF2 - Inverter module 2 temperature 0 °C ~ 140 °C (Only size 14.2) T2B - Internal battery piping...

- Page 49 9 - C O N T R O L...

- Page 50 1 0 - M A I N T E N A N C E M A I N T E N A N C E Saftey Operate in compliance with safety regulations in force. Use single protection devices: gloves, glasses etc. Generality Maintenance must be carried out authorised after-sales assistance centres or by specialised personnel.

- Page 51 1 0 - M A I N T E N A N C E Recommended periodical checks sheet intervention frequency (months) presence corrosion panel fixing fans fixing coil cleaning bowl cleaning + sanitisation outflow test air filters cleaning/inspection air flow rate measurement channelling: anti-vibration devices and fastenings check 10 power supply cable isolation and fastening check 11 earth cable check...

- Page 52 1 0 - M A I N T E N A N C E Structure Check the state of the parts constituting the structure. Treat those parts of the unit subject to oxidation, with paints act at eliminating or reducing the oxidation phenomena. Check fastening of the unit external panelling.

-

Page 53: Electric Heaters

1 0 - M A I N T E N A N C E G4 (ISO 16890 Coarse 60%) Folded air filters It is very important for the air treatment coil to offer maximum thermal exchange: the unit must always work with clean and installed filters. - Page 54 The electronic adjustment is integrated in the filter; maintenance can be carried out without removing it. Materials necessary for maintenance 1 Acid detergent B01212 (code CLIVET C6460316); 2 Plastic or steel tank (750x750x310 mm) with settling bottom 3 Protective gloves and goggles;...

- Page 55 1 0 - M A I N T E N A N C E Ionisation wires The impurities can determine oxidation or scaling on the wires, which can be removed using a cloth soaked in alcohol or an abrasive scourer with very fine grain. Due to the high voltage powering them, the ionisation wires are subject to wear.

- Page 56 1 0 - M A I N T E N A N C E Humidifier cylinder drainage Cylinder must be drained in these situations: cleaning of the cylinder emptying of the cylinder to avoid ice forming replacement of the cylinder ...

- Page 57 1 0 - M A I N T E N A N C E Access to the components - Probes and trasducers 1. Outdoor / return air pressure transducers 6. Return temperature probe 2. Outdoor air humidity probe 7. Delivery pressure transducer 3.

-

Page 58: Standby Mode

1 0 - M A I N T E N A N C E Access to the components - Valves Only size 14.2 Standby mode If a long period of inactivity is foreseen: turn off the power avoid the risk of frost (empty the system or add glycol) ... - Page 59 1 1 - D E C O M M I S S I O N I N G Disconnection WARNIN G Before performing any operation, read the warnings found in the Maintenance chapter. Avoid leak or spills into the environment. Before disconnecting the unit, the following must be recovered, if present: ...

- Page 60 1 2 - R E S I D U A L R I S K S General In this section the most common situations are indicated,as these cannot be controlled by the manufacturer and could be a source of risk situations for people or things.

- Page 61 1 2 - R E S I D U A L R I S K S Electric parts An incomplete attachment line to the electric network or with incorrectly sized cables and/or unsuitable protective devices can cause electric shocks, intoxication, damage to the unit or fires. Carry out all of the work on the electric system referring to the electric layout and the present manual ensuring the use of a system thereto dedicated.

-

Page 62: General Technical Data

General technical data SIZE 10.1 14.2 Cooling Cooling capacity 20,6 30,4 45,7 Sensible capacity 16,5 24,6 35,9 Compressor power input 5,27 8,28 11,5 3,91 3,67 3,97 Cooling capacity (EN 14511:2018) 10 kW 19,0 28,4 42,1 EER (EN 14511:2018) 3,08 2,88 2,97 SEER 4,58... -

Page 63: Sound Levels

Operating range (Cooling) The limits are meant as an indication and they have been calculated by conside- ring: - general and non specific sizes, - standard airflow, - non-critical positioning of the unit and correct operating and maintenance of the unit, - operating at full load To verify the operation field of the operating units with percentages of external air, always calculate the Tm mixing temperature at the internal heat exchanger... -

Page 64: Dimensional Drawings

Dimensional drawings Size 7.1 - Version CAK/CBK/CCK DAA6K0001_7.1_0_REV00 Data/Date 06/11/2017 Compressor compartment 15. Exhaust electric fan (version CCK only) Electrical panel 16. Lifting brackets (removable) Power input 17. Over pressure damper exhaust (version CCK only) Humidifier connections 18. Access for inspection coil, filters, hesting elements Condensate drain 19. - Page 65 Size 10.1 - Version CAK/CBK/CCK DAA6K0002_10.1_0_REV00 Data/Date 06/11/2017 Compressor compartment 15. Exhaust electric fan (version CCK only) Electrical panel 16. Lifting brackets (removable) Power input 17. Over pressure damper exhaust (version CCK only) Humidifier connections 18. Access for inspection coil, filters, hesting elements Condensate drain 19.

- Page 66 Size 14.2 - Version CAK/CBK/CCK DAA6K0003_14.2_0_REV00 Data/Date 06/11/2017 Compressor compartment 15. Exhaust electric fan (version CCK only) Electrical panel 16. Lifting brackets (removable) Power input 17. Over pressure damper exhaust (version CCK only) Humidifier connections 18. Access for inspection coil, filters, hesting elements Condensate drain 19.

- Page 67 Size 7.1 - Version CAK/CBK/CCK - Gas heating module 35/53 kW DAA6K0004_7.1_GC01_GD13_0 REV00 Data/Date 16/11/2017 Compressor compartment 15. Exhaust electric fan (version CCK only) Electrical panel 16. Lifting brackets (removable) Power input 17. Over pressure damper exhaust (version CCK only) Humidifier connections 18.

- Page 68 Size 10.1 - Version CAK/CBK/CCK - Gas heating module 35/53 kW DAA6K0005_10.1_GC01_GD13_0 REV00 Data/Date 06/11/2017 Compressor compartment 15. Exhaust electric fan (version CCK only) Electrical panel 16. Lifting brackets (removable) Power input 17. Over pressure damper exhaust (version CCK only) Humidifier connections 18.

- Page 69 Size 14.2 - Version CAK/CBK/CCK - Gas heating module 35/100 kW DAA6K0006_14.2_GC01_GD15_0 REV00 Data/Date 06/11/2017 Compressor compartment 15. Exhaust electric fan (version CCK only) Electrical panel 16. Lifting brackets (removable) Power input 17. Over pressure damper exhaust (version CCK only) Humidifier connections 18.

- Page 70 sales and assistance...

Need help?

Do you have a question about the CKN-XHE2i and is the answer not in the manual?

Questions and answers