Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Xylem Flygt 3090

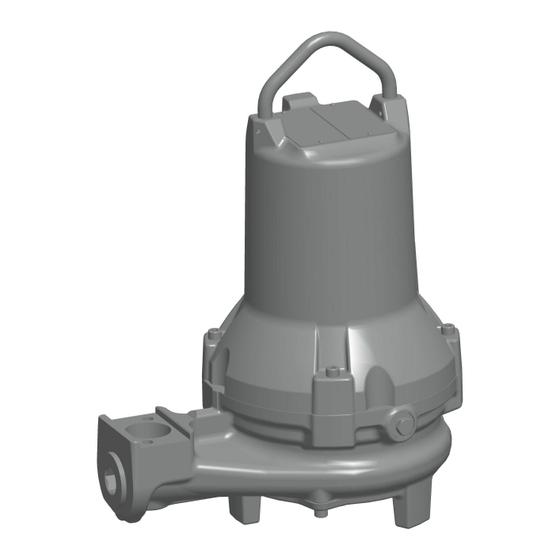

- Page 1 Installation, Operation, and Maintenance Manual 899403_15.0 Flygt 3090...

-

Page 3: Table Of Contents

4.4.5 Connect the motor cable to the starter and monitoring equipment....... 23 4.4.6 Cable charts......................23 4.5 Check the impeller rotation..................32 5 Operation........................... 33 5.1 Precautions........................33 5.2 Estimate zinc anode replacement intervals..............33 5.3 Start the pump......................34 Flygt 3090 Installation, Operation, and Maintenance Manual... - Page 4 7.4 The pump starts-stops-starts in rapid sequence............44 7.5 The pump runs but the motor protection trips..............45 7.6 The pump delivers too little or no water...............46 8 Technical Reference......................47 8.1 Application limits......................47 8.2 Motor data........................47 Flygt 3090 Installation, Operation, and Maintenance Manual...

-

Page 5: Introduction And Safety

This includes any modification to the equipment or use of parts not provided by Xylem. If there is a question regarding the intended use of the equipment, please contact a Xylem representative before proceeding. -

Page 6: User Safety

These are the personnel requirements for Ex-approved products in potentially explosive atmospheres: • All work on the product must be carried out by certified electricians and Xylem authorized mechanics. Special rules apply to installations in explosive atmospheres. • All users must know about the risks of electric current and the chemical and physical characteristics of the gas, the vapor, or both present in hazardous areas. -

Page 7: Special Hazards

• Do not modify the equipment without approval from an Ex-approved Xylem representative. • Only use original Xylem spare parts that are provided by an Ex-approved Xylem representative. • The thermal contacts that are fitted to the stator windings must be connected correctly to a separate motor control circuit and in use. -

Page 8: Wash The Skin And Eyes

• Clean-up of spills Exceptional sites CAUTION: Radiation Hazard Do NOT send the product to Xylem if it has been exposed to nuclear radiation, unless Xylem has been informed and appropriate actions have been agreed upon. 1.7 End-of-life product disposal Handle and dispose of all waste in compliance with local laws and regulations. -

Page 9: Transportation And Storage

Never lift the unit by its cables or hose. Lifting points The following images show the lifting points for the different installation types. For more Installation information about the installation types, see on page 16. Flygt 3090 Installation, Operation, and Maintenance Manual... -

Page 10: Temperature Ranges For Transportation, Handling And Storage

• The minimum height between the lifting hook and the floor must be sufficient to lift the unit. Contact a Xylem representative for more information. • The lifting equipment must be able to hoist the unit straight up and down, preferably without the need for resetting the lifting hook. -

Page 11: Storage Guidelines

If the packaging material has an indicated stacking limit, then it is valid for 23°C (73°F) and 50% relative humidity. Depending on the material, other temperature and humidity ranges can reduce the stacking limit. Flygt 3090 Installation, Operation, and Maintenance Manual... -

Page 12: Product Description

• Modifications to the unit or installation should only be carried out after consulting with Xylem. • Original spare parts and accessories that are authorized by Xylem are essential for compliance. The use of other parts can invalidate any claims for warranty or compensation. -

Page 13: Sensors And Monitoring Equipment

• The thermal contacts open at 140°C (285°F). • Ex-approved pumps must have thermal contacts connected to the control panel. • The sensors must be connected to either the MiniCAS II monitoring equipment or an equivalent equipment. Flygt 3090 Installation, Operation, and Maintenance Manual... -

Page 14: The Data Plate

This product is submersible and therefore exempted from the motor efficiency requirement, in accordance with EU commission regulation 2019/1781 Article 2(2)(e). 3.5 Approvals 3.5.1 Product approvals for hazardous locations 3090 This table shows product approvals for the following products: • 3090.890 Flygt 3090 Installation, Operation, and Maintenance Manual... - Page 15 6. Starting current or Rated current 7. Duty class 8. Duty factor 9. Input power 10. Rated speed 11. Additional information 12. Maximum ambient temperature 13. Serial number 14. ATEX marking 15. Country of origin WS001279D Flygt 3090 Installation, Operation, and Maintenance Manual...

-

Page 16: Product Denomination

In this section, code characters are illustrated accordingly: X = letter Y = digit The different types of codes are marked up with a, b and c. Code parameters are marked up with numbers. Flygt 3090 Installation, Operation, and Maintenance Manual... - Page 17 XXYYYY YYY YYY YYYY Type of Callout Number Indication Type of code Sales denomination Product code Serial number Parameter Hydraulic end Type of installation Sales code Version Production year Production cycle Running number Flygt 3090 Installation, Operation, and Maintenance Manual...

-

Page 18: Installation

• Only use fasteners of the correct size and material. • Replace all corroded or damaged fasteners. • Make sure that all the fasteners are correctly tightened and that there are no missing fasteners. Flygt 3090 Installation, Operation, and Maintenance Manual... -

Page 19: Install With P-Installation

6. Prepare the connection between the pump housing and the discharge connection. a) Remove the plug from the pump housing. b) Remove the O-ring from the plug. c) Fit the O-ring in the groove in the pump housing. Flygt 3090 Installation, Operation, and Maintenance Manual... -

Page 20: Install With H-Installation

Remove the plug from the pump housing. b) Remove the O-ring from the plug. c) Refit the plug to the pump housing. Tightening torque: 40 Nm (30 ft-lbs) 3. Fit the pipe and connect the discharge connection. Flygt 3090 Installation, Operation, and Maintenance Manual... -

Page 21: Make The Electrical Connections

• The mains voltage and frequency must agree with the specifications on the data plate. If the pump can be connected to different voltages, then follow the specified voltage on the yellow sticker close to the cable entry. Flygt 3090 Installation, Operation, and Maintenance Manual... -

Page 22: Grounding (Earthing)

Grounding (earthing) must be done in compliance with all local codes and regulations. DANGER: Electrical Hazard All electrical equipment must be grounded (earthed). Test the ground (earth) lead to verify that it is connected correctly and that the path to ground is continuous. Flygt 3090 Installation, Operation, and Maintenance Manual... -

Page 23: Prepare The Subcab ™ Cables

The aluminum foil is a conductive screen. Do not peel more than necessary, and remove the peeled foil. Figure 6: Aluminum foil on the control element. c) Put a white shrink tube over the drain wire. Flygt 3090 Installation, Operation, and Maintenance Manual... -

Page 24: Connect The Motor Cable To The Pump

7. Install the entrance cover and the O-ring on the stator housing. 8. Fasten the screws on the entrance flange so that the cable insertion assembly bottoms out. Flygt 3090 Installation, Operation, and Maintenance Manual... -

Page 25: Connect The Motor Cable To The Starter And Monitoring Equipment

Check that the relays, lamps, fuses, and connections are intact. Replace any defective equipment. 4.4.6 Cable charts Description This topic contains general connection information. It also provides cable charts that show connection alternatives for use with different cables and power supply. Flygt 3090 Installation, Operation, and Maintenance Manual... - Page 26 3. Power cable leads L1 L2 L3 T1 T2 T3 T4 4. Stator (internal connection illustrated) U1 V1 W1 W2 V2 U1 V1 W1 W2 U2 V2 U1 V1 W1 W2 U2 V2 L2 L3 Flygt 3090 Installation, Operation, and Maintenance Manual...

- Page 27 * * Ground Conductor is stranded around cores Screen (WH) Screen (WH) Screen (WH) GC=Ground Check 863 17 00 (REV 2) Figure 8: 3–phase and 1–phase without built-in starter Sensors connection For markings on sensor leads, see on page 30. Flygt 3090 Installation, Operation, and Maintenance Manual...

- Page 28 U1 V1 W1 W2 U2 V2 L1 L2 L3 L3:1 L2:1 L1:1 U1 V1 W1 W2 U2 V2 L3:2 L2:2 L1:2 U1 V1 W1 W2 U2 V2 U1 V1 W1 W2 U2 V2 L1 L2 L1 L2 L3 Flygt 3090 Installation, Operation, and Maintenance Manual...

- Page 29 4 Installation 9 Leads U1 V1 W1 U5 V5 W5 U2 W2 U1 V1 W1 U1 V1 W1 L1 L2 Y-SER U5 U2 V1 V5 V2 W1 W5 W2 Flygt 3090 Installation, Operation, and Maintenance Manual...

- Page 30 U1 V1 W1 W2 U2 V2 Y-SER U1 V1 W1 W2 U2 V2 W5 U5 V5 U6 W6 U1 V1 W1 W2 U2 V2 U1 V1 W1 W2 U2 V2 D-SER 460V 230V WS004128C Flygt 3090 Installation, Operation, and Maintenance Manual...

- Page 31 4 Leads Starter 4 Leads with level regulator U1 Z1 Starter 12 Leads U1 V1 U6 Starter Figure 9: Without built-in starter Colors and markings of leads For more information, see on page 25. Flygt 3090 Installation, Operation, and Maintenance Manual...

- Page 32 SUBCAB Control SUBCAB AWG Screenflex screened WH T1 WH T1 WH T2 WH T2 WH T3 WH T4 *If Y/D-start, sensors not connected (Thermal Contacts) WH/YE Control leads T1/*OG/4 WH/YE T2/*OG/5 *SUBCAB AWG Flygt 3090 Installation, Operation, and Maintenance Manual...

- Page 33 For non Ex-pumps: Temp > 40° T1,T2 thermal contacts not connected WH/YE WH/YE Sensor connection characteristics The values have a 10 % tolerance. Sensors Value (mA) Definition FLS and thermal contact Overtemperature Leakage Flygt 3090 Installation, Operation, and Maintenance Manual...

-

Page 34: Check The Impeller Rotation

– If the motor has a 1-phase connection, then contact a sales or authorized service representative. – If the motor has a 3-phase connection, then transpose two phase leads and do this procedure again. Flygt 3090 Installation, Operation, and Maintenance Manual... -

Page 35: Operation

2. After two months, remove and weigh the same zinc anode or anodes again. 3. Divide the lapsed time in days (between steps 1 and 2) by the anode weight loss in grams to get the calculated anode consumption rate (days/gram). Flygt 3090 Installation, Operation, and Maintenance Manual... -

Page 36: Start The Pump

Never put your hand into the pump housing. 3. Conduct insulation test phase to ground. To pass, the value must exceed 5 megaohms. 4. Check that the monitoring equipment (if any) works. 5. Start the pump. Flygt 3090 Installation, Operation, and Maintenance Manual... -

Page 37: Maintenance

• Lubricate all springs, screws, O-rings with grease. During the reassembly, always make sure that existing index markings are in line. The reassembled drive unit must always be insulation-tested and the reassembled pump must always be test-run before normal operation. Flygt 3090 Installation, Operation, and Maintenance Manual... -

Page 38: Torque Values

The torque values are only valid for the set screw, and not for the round nut. 18 (13) 35 (26) 6.4 Change the oil This image shows the plugs that are used to change the oil. Flygt 3090 Installation, Operation, and Maintenance Manual... - Page 39 Allow the chamber to de-pressurize before removal of the plug. 1. Place the pump in a horizontal position and unscrew the oil plug. WS001760A 2. Place a container under the pump and turn the pump. 3. Unscrew the other oil plug. WS001761A Flygt 3090 Installation, Operation, and Maintenance Manual...

-

Page 40: Service The Pump

Up to every five years as impeller trimming, wear part control and Applies to application with M-impeller with replacement, control of zinc-anodes and usage < 10 min/day and approximately control of the stator. 10 starts/day. Flygt 3090 Installation, Operation, and Maintenance Manual... -

Page 41: Inspection

Oil housing Fill with new oil, if necessary. Terminal block/closed end splice Check that the connections are properly tightened/connected. Thermal contacts Normally closed circuit; interval 0–1 ohm. Voltage and amperage Check the running values. Flygt 3090 Installation, Operation, and Maintenance Manual... -

Page 42: Overhaul

• Impeller puller If applicable, contact your local sales and service representative for correct type and size. • Two crowbars, if applicable CAUTION: Cutting Hazard Worn parts can have sharp edges. Wear protective clothing. Flygt 3090 Installation, Operation, and Maintenance Manual... -

Page 43: Remove The Impeller: M

4. Adjust the impeller: a) Make sure that the impeller makes contact with the suction cover. Use two screw drivers inserted in the groove of the impeller to carefully adjust the impeller outwards. Flygt 3090 Installation, Operation, and Maintenance Manual... - Page 44 7. Fit and tighten the set screw. Tightening torque: 44 Nm (32 ft-lbs) 8. Check with a feeler gauge 0,3 mm that the clearance does not exceed 0,3 mm on any of the 3 cutting blades. Flygt 3090 Installation, Operation, and Maintenance Manual...

-

Page 45: Troubleshooting

• The start level regulator is functioning. Clean or replace if manually. necessary. • All connections are intact. • The relay and contactor coils are intact. • The control switch (Man/Auto) makes contact in both positions. Check the control circuit and functions. Flygt 3090 Installation, Operation, and Maintenance Manual... -

Page 46: The Pump Does Not Stop When A Level Sensor Is Used

• The distance between the start and stop levels is sufficient. level again. • The non-return valve(s) work(s) properly. • The length of the discharge pipe between the pump and the first non-return valve is sufficiently short. Flygt 3090 Installation, Operation, and Maintenance Manual... -

Page 47: The Pump Runs But The Motor Protection Trips

There is a malfunction in the Replace the overload protection. overload protection. If the problem persists, then contact a sales or authorized service representative. Product Description Always state the serial number of the product, see on page 10. Flygt 3090 Installation, Operation, and Maintenance Manual... -

Page 48: The Pump Delivers Too Little Or No Water

• Depending on the installation type, add a means for priming the pump, such as a foot valve. If the problem persists, then contact a sales or authorized service representative. Product Description Always state the serial number of the product, see on page 10. Flygt 3090 Installation, Operation, and Maintenance Manual... -

Page 49: Technical Reference

IEC 60034-1 Voltage variation ±10%, if it does not run continuously at full load without overheating Voltage imbalance tolerance Stator insulation class H (180°C [356°F]) Motor encapsulation Motor encapsulation is in accordance with IP68. Flygt 3090 Installation, Operation, and Maintenance Manual... - Page 52 For more information on how Xylem can help you, go to www.xylem.com Xylem Water Solutions Global Visit our Web site for the latest version of this document...

Need help?

Do you have a question about the Flygt 3090 and is the answer not in the manual?

Questions and answers