Subscribe to Our Youtube Channel

Summary of Contents for Halma COSASCO RSL

- Page 1 COSASCO® RSL RETRIEVER AND DOUBLE ISOLATION SERVICE VALVE WORK INSTRUCTION P/N – 741039 Revision – R services@cosasco.com www.cosasco.com Los Angeles Houston Aberdeen Perth Beijing Dubai Malaysia Singapore...

- Page 2 August 2023 Review Date: December 2024 Revision History Record Page Date Description of Change Issue Reviewed Approved 2/15/13 Initial Release 3/05/13 General Revision 4/11/13 Added Disclaimer Notes 8,13,15, 8/20/13 Added Revision History, Improvements to 18, 21, document in line with Shell's docs. 01/30/14 Annual Review 03/25/15...

- Page 3 August 2023 Review Date: December 2024 Revision History Record Continued Page Date Description of Change Issue Reviewed Approved 22306 18/07/22 Annual Review Updated Section 6.2 - Critical Step Checklist Annual Review 22488 08/08/23 sales@cosasco.com www.cosasco.com Los Angeles Houston Aberdeen Perth Beijing Dubai Malaysia...

- Page 4 August 2023 Review Date: December 2024 Cosasco® is a registered trademark of Rohrback Cosasco Systems, Inc. No part of this work instruction may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying and recording, for any purpose, without the express written permission of Rohrback Cosasco Systems, Inc.

-

Page 5: Table Of Contents

August 2023 Review Date: December 2024 CONTENTS Page No IMPORTANT INSTRUCTIONS ....................5 DISCLAIMER ..........................6 SAFETY WARNINGS ......................... 7 SCOPE OF DOCUMENT ......................8 HOW THE COSASCO SYSTEM WORKS ..................8 Access Fittings ......................... 8 The Retrieval Tool ........................10 The Service Valves (Double Isolation) ................... -

Page 6: Important Instructions

Cosasco RSL Retrieval tool and Double Isolation Service Valve. This work instruction is not meant to be a sole source of instruction or training guide. -

Page 7: Disclaimer

August 2023 Review Date: December 2024 Product Operation Personnel (Personnel): 1. Read and understand all instructions and operating procedures for this product. 2. Follow all warnings, cautions and notices marked on and supplied with this product. 3. Follow all instructions during the installation, operation and maintenance of this product. 4. -

Page 8: Safety Warnings

August 2023 Review Date: December 2024 SAFETY WARNINGS It is imperative that the following safety warnings are taken into important WARNING consideration before and during use of Retrieval Equipment. Safety warnings are noted throughout this document to ensure precautions are taken for all procedures where there are risks involved. -

Page 9: Scope Of Document

SCOPE OF DOCUMENT This document details the procedure for the installation and retrieval of corrosion and erosion monitoring devices or chemical injection equipment using the Cosasco RSL Retrieval Tool and Double Isolation Service Valve from 2” system access fittings. Also included is the use of special ancillary tools in conjunction with the Retrieval tool and Service Valve. These tools are designed to allow installation and retrieval of the above mentioned devices from access fittings without shutdown when production pipework is at full operating pressure. - Page 10 August 2023 Review Date: December 2024 The COSASCO Access Fitting Assembly is the key to the concept of “Access under pressure - any time, any place”. When used with a COSASCO Retrieval tool and Service Valve, the Access Fitting Assembly permits safe, easy insertion and retrieval of corrosion and erosion monitoring systems as well as preventive maintenance devices for injecting inhibitors or for sampling, etc.

-

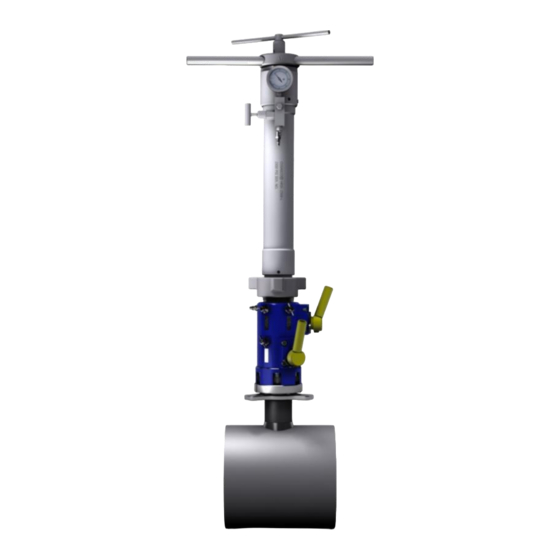

Page 11: The Retrieval Tool

August 2023 Review Date: December 2024 The Retrieval Tool The standard RSL retrieval tool features a stainless steel outer barrel, Viton O-rings and graphite impregnated Teflon seals. They are pressure rated up to 6000 psi (414 barg) and have a maximum operating temperature of +400°F (+204°C) and meet the NACE MR0175 standard. -

Page 12: The Service Valves (Double Isolation)

August 2023 Review Date: December 2024 The most commonly used retrieval tools come in 18”, 25” & 37” stroke lengths. The stroke length determines the length of device the retrieval tool can accommodate for installation or retrieval. Some useful retrieval tool specifications are included in the table below. DBBV 6000 PSI DBBV 3600 PSI RSL-... -

Page 13: Back Pressure Pump

August 2023 Review Date: December 2024 Back Pressure Pump To ensure safe working practices, a Back Pressure Pump must be used with all COSASCO Retrieval tools. "Back Pressuring" pressurizes the retrieval tool to a pressure slightly higher than the line pressure, thereby preventing a surge of pressure when the carrier plug assembly is removed. -

Page 14: Pre Job Preparation

August 2023 Review Date: December 2024 6 PRE JOB PREPARATION The following three sections discuss the major steps required, prior to starting any on-line retrieval using the RSL Retrieval Tool and Service Valve. The lists in the following sections are prompts and are not intended to replace client Risk Assessments or Job Safety Analysis, which will also have to be completed prior to work start. -

Page 15: On-Site Equipment And Worksite Checks

August 2023 Review Date: December 2024 A toolbox talk will be performed by the lead Engineer (Cosasco or Client), including but not limited to the following: • The main steps involved in the job • Equipment to be used • Review of work permit and risk assessment •... -

Page 16: Retrieval And Installation Of Devices From 2" System Access Fittings

August 2023 Review Date: December 2024 If a situation arises during the execution of this Work Instruction, which requires a deviation, then an approved Job Step Analysis will be required before continuing with the WARNING operations at the monitoring location concerned. The JSA must be approved by Cosasco and by the Operator of the site before proceeding with the deviation. -

Page 17: Access Fitting Preparation & Installation Of Service Valve

August 2023 Review Date: December 2024 4. Once the cap has been confirmed free of pressure, unscrew the cap using a C spanner. If a Swagelok probe adapter is installed through the cap, the adapter will have to be removed prior to removal or turning of the cap. -

Page 18: Back Pressuring Procedure - Device Retrieval

August 2023 Review Date: December 2024 3. Double check that the Retrieval tool bleed valve is closed & Service Valve bleed and bypass valves are closed. Double check that both the Retrieval tool bleed valve and Service Valve bleed valve WARNING! and bypass valves are closed! Leakage will result when carrier plug assembly is disengaged. - Page 19 August 2023 Review Date: December 2024 Back Pressuring Procedure - Device Retrieval Retrieval tool, Service valve and Back Pressure Pump with Hose must be IMPORTANT! pressure tested prior to assure safe operation of tools! Back pressuring the retrieval tool involves connecting a high pressure pump or other means of pressurization, such as nitrogen bottle via a hose, to either the valve bleed port or retrieval tool bleed port.

- Page 20 August 2023 Review Date: December 2024 4. Connect other end of hose to retrieval tool or Service Valve (depending on orientation) via the quick connect coupling. 5. Fill pump reservoir with desired fluid, potable water will normally be used although hydraulic oil can be used if required.

- Page 21 August 2023 Review Date: December 2024 • The nitrogen bottle pressure be at least 200 psi (13 bar) higher than the line pressure. • The nitrogen bottle be equipped with a regulator. • The nitrogen bottle be fitted with a bleed valve. (This is desirable to allow bleeding down the hose after back pressuring is completed).

-

Page 22: Removal Of Carrier Plug

August 2023 Review Date: December 2024 Removal of Carrier Plug 1. Rotate the translation handle clockwise to move the socket adapter over the top of the carrier plug. Once at the top of the carrier plug, rotate the rotation handle clockwise to thread the socket adapter into the carrier plug assembly. -

Page 23: Preparation Of The Carrier Plug & Device

August 2023 Review Date: December 2024 WARNING! Make sure Retrieval tool has been completely depressurized! Leakage will result when Retrieval tool is removed from Service Valve if not completely depressurized. Leakage of volatile or high temperature media could result in serious injuries! 8. -

Page 24: Installation Of Retrieval Tool

August 2023 Review Date: December 2024 Any carrier plugs found to be damaged should be replaced with new carrier plugs. Do not re-dress carrier plugs. Fit a new primary packing after each service, and for a solid carrier plug, replace the secondary O’... -

Page 25: Back Pressure Retrieval Tool - Device Installation

August 2023 Review Date: December 2024 3. Inspect the mating retrieval tool to valve O ring seal on the retrieval tool and ensure there are no nicks, abrasions or damage etc. If damaged this seal should be replaced immediately. 4. With two Cosasco trained operators mate the retrieval tool to the service valve by lifting the retrieval tool in to position then tighten the retrieval tool hammer union clockwise and tighten using a non-sparking hammer. - Page 26 August 2023 Review Date: December 2024 1. Attach quick connect fitting to Service Valve bleed port or retrieval tool bleed port. 2. Attach high pressure hose to pump. Note - Pump, hose and all connections must be pressure rated to at least the same pressure rating of retrieval tool.

- Page 27 August 2023 Review Date: December 2024 1. Connect a high pressure hose to the Retrieval tool bleed valve or Service Valve bleed valve. 2. Nitrogen bottle connection. Connect the other end of the high pressure hose to the nitrogen bottle outlet. It is recommended that: •...

-

Page 28: Installation Of The Carrier Plug

August 2023 Review Date: December 2024 Installation of the Carrier Plug Once the equipment has been pressured to line pressure then the upper and lower ball can be opened to allow installation of the carrier plug and monitoring device. 1. Slowly open the by-pass valve for the upper ball (closest to the retrieval tool). Slowly open the upper ball fully. - Page 29 August 2023 Review Date: December 2024 5. Tighten the carrier plug using sufficient force to obtain a seal. Do not fully compress the seal, as this will prevent orientation of the carrier plug. 6. Once the carrier plug is fully installed, release pressure from the Retrieval tool in a controlled manner using either the Service Valve or Retrieval tool bleed valve into a suitable container to catch fluids.

-

Page 30: Carrier Plug Orientation & Access Fitting Cap Installation

August 2023 Review Date: December 2024 7.10 Carrier Plug Orientation & Access Fitting Cap Installation 1. Wipe the access fitting until clear of any residues. If the installed device requires orientating with the pipe line flow direction, identify the mark on the hex of the carrier plug and using the retrieval tool turn the carrier plug clockwise until the mark is in the desired position to achieve orientation. - Page 31 August 2023 Review Date: December 2024 • Apply thread sealant to the threaded section closest to the probe pin receiver holes on the probe extension adapter. • Position the male / male threaded part of the adapter as close to the probe pin receiver holes as possible and the female Swage nut at the top of the adapter nearest the instrument connection pins •...

-

Page 32: Special Tools & Procedures

August 2023 Review Date: December 2024 SPECIAL TOOLS & PROCEDURES The RSL Retrieval tool can be used with a number of ancillary tools and equipment which can aid with the servicing of an access fitting and may be essential in some circumstances as mentioned during earlier stages of this procedure. - Page 33 August 2023 Review Date: December 2024 o If the equipment is stored for a time period greater than 7 days from servicing, but no longer than 6 months it may be mobilized for further service work without being re-serviced, provided that a new successful pressure test has been completed within the 7 days prior to mobilization.

- Page 34 August 2023 Review Date: December 2024 Pressure Testing Procedure 1. Fit the Service Valve to the access fitting on the pressure test rig by placing the hammer nut end of the valve onto the access fitting. 2. Turn the hammer nut clockwise down the external acme thread until the Service Valve is securely seated to the access fitting body.

- Page 35 August 2023 Review Date: December 2024 13. Ensure the bleed to atmosphere valve(s) on the Service Valve is closed and the Retrieval tool bleed to atmosphere valve is opened. 14. With the hydraulic pump on "Pressure Hold” and at its low-pressure setting hand pump the oil through the Service Valve and into the Retrieval Tool, ensuring the isolating valve is fully opened.

-

Page 36: Thread Chaser Assembly (P/N 125102)

August 2023 Review Date: December 2024 Thread Chaser Assembly (P/N 125102) It is assumed from the start of this procedure that the Service Valve is in the closed position and holding line pressure, with the internal threads of the access fitting requiring cleaning or repair. 9. - Page 37 August 2023 Review Date: December 2024 15. Once the service valve ball valve is verified as holding line pressure, release pressure from retrieval tool gradually using either the service valve or retrieval tool bleed valve into a suitable container to catch fluids. 16.

-

Page 38: Overshot Adapter (P/N 126292)

August 2023 Review Date: December 2024 Overshot Adapter (P/N 126292) The overshot adapter can be used when there is pressure located beneath the ½” pipe plug located in the hex of a hollow carrier plug. With the overshot installed as an extension of the carrier plug hex the ½” pipe plug remains in place. -

Page 39: Surge Tube Assembly (P/N 123672)

August 2023 Review Date: December 2024 Surge Tube Assembly (P/N 123672) The surge tube assembly is used to flush debris from the access fitting body by using line pressure. Surge Tube Assembly - Low Pressure Lines For LOW PRESSURE lines:(pressures lower than 250 psi -17 BAR), follow the steps below. IMPORTANT! WEAR SAFETY GLASSES! USE NON-SPARKING HAMMER! 1. - Page 40 August 2023 Review Date: December 2024 Surge Tube Assembly - High Pressure Lines For HIGH PRESSURE lines: (pressures higher than 250 psi -17 BAR), follow the steps below. IMPORTANT! WEAR SAFETY GLASSES! USE NON-SPARKING HAMMER! 1. Connect the surge tube assembly. Lift the surge tube assembly and place the hammer nut end on the service valve.

-

Page 41: Thread Brush Assembly (P/N 125116)

August 2023 Review Date: December 2024 Thread Brush Assembly (P/N 125116) The thread brush assembly is used to clean small amounts of debris from the access fitting body threads. 1. Attach the thread brush assembly to the socket adapter pilot threads. IMPORTANT! WEAR SAFETY GLASSES! USE NON-SPARKING HAMMER! 2. -

Page 42: Seat Reamer (P/N 125125)

August 2023 Review Date: December 2024 Seat Reamer (P/N 125125) The Seat Reamer is used to clean small amounts of debris from the access fitting body seat. 1. Attach the seat reamer to the socket adapter pilot threads. IMPORTANT! WEAR SAFETY GLASSES! USE NON-SPARKING HAMMER! 2. -

Page 43: Steel Pipe Plug Adapter (P/N 125115)

August 2023 Review Date: December 2024 Steel Pipe Plug Adapter (P/N 125115) The steel pipe plug adapter is used to install or allow retrieval of the 1/2" steel pipe plug, while carrier plug assemblies are under pressure. This tool is used in cases where bleed-off cannot be accomplished. The procedure described for the steel pipe plug adapter differs from the other tools described in this section in that the service valve is assumed not to be installed and that the carrier plug assembly is assumed to be present within the access fitting body. -

Page 44: Go Gauge (P/N 741104-1/2/3)

August 2023 Review Date: December 2024 8. Using the brass hammer tap loose the retrieval tool hammer nut and unscrew fully. Lift the retrieval tool from the service valve. 9. Rotate the translation handle clockwise to expose the socket adapter, the attached pipe plug adapter and the pipe plug. - Page 45 August 2023 Review Date: December 2024 sales@cosasco.com www.cosasco.com Los Angeles Houston Aberdeen Perth Beijing Dubai Malaysia Singapore...

Need help?

Do you have a question about the COSASCO RSL and is the answer not in the manual?

Questions and answers