Summary of Contents for Morbark BEEVER M18R

- Page 1 BEEVER M18R Wood Chipper S/N 52034 Read this manual before operating the chipper 76347-282 • 12-08...

- Page 2 PLACE PLACE MORBARK MORBARK PARTS SAFETY VIDEO VIDEO HERE HERE...

- Page 3 All rights reserved. This book is protected by copyright. No part of this book may be reproduced in any form or by any means including photocopying, or utilized by any information storage and retrieval system without written permission from Morbark Inc. Printed in the United States of America.

- Page 4 PARTS MANUAL REVISION LOG Revision: Date Issued: Pages Affected: Description of Changes: Sept 28, 2015 Initial Release Jan, 23, 2019 Part # Update 3 May 16, 2019 4.8, 4.9 Item 28 part number Item Axle S/N: Engine S/N: WARNING! Engine Pump P/N: Clutch S/N:...

- Page 5 If for any reason you need to correspond with us, or any of the Morbark The five distinct sections are Safety, Chipping Cycle, Features & Function, dealers, please have the serial number handy. It is located on the front Parts, and Maintenance.

- Page 6 Contents Section 1 • Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 . 1 Section 2 •...

-

Page 7: Table Of Contents

Safety Section 1 Symbols, Signs, and Terms ....... . . 1.2 General Operator Training. -

Page 8: Symbols, Signs, And Terms

Safety • Symbols, Signs, and Terms Symbols, Signs, and Terms Warning Symbol Graphics Think Safety Throughout this manual, and on the decals of your machine, you will find Safety is a combination of common sense and alertness at all times when many types of safety symbols. -

Page 9: General

Safety • General General Figure 1.1 Personal Protection Safety is No Accident Accidents don’t just happen; they are usually caused when people make mistakes, are not properly trained, or do not have full understanding of how the machine operates. Clothing and Gear Wear proper protective equipment It is mandatory that employers/owners have safety and operating procedures and clothing at all times. -

Page 10: Operation

• Water tanks and halon gas extinguishers are recommended • Communication device (e.g., cell phone, walkie talkie) • Fully stocked first aid kit. (Can be ordered from Morbark P/N 59135-245) Maintenance • Clean dirt, oil, wood chips, and bark from engine area. Remove debris and accumulated oil, grease, and other flammable material from around the power unit and bearings daily •... -

Page 11: Shutdown

Safety • General Spectators, Children, and Untrained Individuals Handling • Do not allow children or spectators to operate the machine or play • Do not climb, sit, stand, or lay on the machine during operation near the machine during operation •... - Page 12 Safety • General Transporting Boxer General Operation Standards NOTE: Your Boxer must be backed onto the Chipper when loading. • From front of machine, pull hair pin, lift bolt, and slide ramps out of their transport position shown in (figure 1.2) NOTE: When stowing ramps reverse steps described above.

- Page 13 Safety • General Figure 1.2 Figure 1.3 Figure 1.4 Figure 1.5 76347-282 • 12-08...

-

Page 14: Safety Checklist

Safety • Start-up Checklist Safety Checklist Be sure to check that you have the following items at the beginning of Fuel and oil line connections are securely attached to the fittings and each session or when changing operators: there is no sign of fluid leakage. Tubes and hoses are in good condition Filler caps and drain plugs are securely attached to the machine Emergency equipment on work site: •... -

Page 15: Lockout Procedure

• Each person authorized to lockout the machine must have a safety lock and key dedicated to the machine lockout Morbark chippers are custom built to customer specifications. Control • Authorized personnel must verbally notify affected employees of the panels, power configurations, and other features may differ from each machine lockout, and post a sign(s) indicating the power lockout machine. - Page 16 Safety • Lockout Procedure • Equipment with main disconnect switches shall be turned off and A. Ensure that the continuity of the lockout procedure locked in the OFF position only after the source of electrical power is is maintained shut off at the point of operational control B.

-

Page 17: Safety Lockout Instructions

Safety • Lockout Procedure Safety Lockout Instructions: To Lockout the Yoke: Remove the yoke locking pin from its holder. Insert the hitch clip into the hole at the end of the yoke locking pin. Raise the yoke past the hole for the locking pin by moving the yoke Check that the hitch clip is securely in place by pulling on the handle valve lever in the direction indicated by the decal next to your valve of the yoke locking pin, and attempt to remove it. - Page 18 Safety • Lockout Procedure To Lockout the drum: Slide back the hood locking pins that holds the drum hood down. Lift Figure 1.12 Drum locking pin the drum hood open. Turn the drum manually until the slot in the wheel is aligned with the holes on the side of the drum base.

-

Page 19: Crime Prevention

Safety • Crime Prevention Crime Prevention • Maintain an inventory record of all equipment and machines. Regularly check to make sure that no machines have been stolen Parking Indoors • Remove the ignition key and place hard-to-move equipment in front of exits It has been proven that thieves are hesitant to take items that can be readily identified. -

Page 20: Safety Decals And Locations

Safety • Safety Decals Safety Decals and Locations Control Panel Figure 1.14 39511-422 Warning - Fire Hazard Moving parts can crush and cut Follow lockout procedures DANGER! before servicing. Moving parts can crush and cut 39511-320 Follow lockout procedures before servicing. 39511-320 Danger - Moving Parts 39511-320 39511-010 Made in USA... -

Page 21: Right View

Safety • Safety Decals Right View Figure 1.15 39511-406 Danger Crush Hazard 39511-427 39511-427 Danger 39511-405 Danger 39511-401 Flying Material Crush Hazard Danger Rotating Blades 39511-234 Warning - Stay Clear DANGER! Moving parts can crush and cut Follow lockout procedures before servicing. -

Page 22: Left View

Safety • Safety Decals Left View Figure 1.15 Moving parts can crush and cut Follow lockout procedures before servicing. 39511-320 39511-320 Danger - Lockout 39511-405 Danger Crush Hazard 39511-426 Warning - Always Lock 39511-428 Danger -Flying Material 39511-416 Warning - Feed System DO NOT reach into the infeed chute. - Page 23 The Chipping Cycle Section 2 Preparation Preparation and Set-up ....... 2.2 Start-up Fluid Levels .

-

Page 24: Preparation

The Chipping Cycle • Preparation Preparation This section is an overview of the chipping process. It is mandatory that all personnel handling, operating, and maintaining this machine read the manual completely and be properly trained on its use. Operators should also review the manual on a regular basis. Specific information on safety, function, use, and maintenance of a machine feature is also located in the Features and Function section. - Page 25 The Chipping Cycle • Preparation Brush Preparation Figure 2.1 DANGER! No wider than infeed opening Foreign material (metal, stones, glass) in the chipper will cause damage and potentially shatter the cutting blades resulting in property damage, serious injury, or death. Vines left on the wood may cause entanglement of operating personnel, or hide foreign material resulting in equipment damage, serious injury, or death.

- Page 26 The Chipping Cycle • Preparation Machine Preparation Adjust discharge chute DANGER! Once you have the machine secured and level, the next step in machine preparation is setting up the discharge chute. See page 3.18 in the Features and Function section for more detail. Before operating, always block the wheels and ensure the chipper is on stable level ground when not attached to a •...

- Page 27 The Chipping Cycle • Preparation Figure 2.3 Note: Some machines have a height adjustor. See the Features and Function section to adjust the height of the discharge chute using the height adjustor Adjust angle of wood chip projection Infeed spout is clear of debris Chipper should sit on a level surface with the...

-

Page 28: Start-Up

The Chipping Cycle • Start-up Start-up Fluid Levels Before you start the machine it is important to check the fuel, hydraulic oil, and radiator coolant levels. Allow the machine to cool down before adding DANGER! oil, fuel, or radiator coolant. Remove the cap slowly to relieve pressure. Engine start-up: Exposing diesel fuel to an ignition source such as a flame Place the safety control bar into the neutral position. - Page 29 The Chipping Cycle • Start-up Figure 2.6 After Engine warm-up: Neutral Hydraulic valve will Go to full throttle. Keep it at this speed during the chipping process. move into the neutral Forward position when Figure 2.5 pulls material into released the feed wheels Disengage clutch Engage clutch...

-

Page 30: Chipping The Wood

Getting Started • Chipping Wood Chipping Wood Figure 2.7 Feeding Brush into the Chipper When you are about to feed brush into the chipper, position the throttle at full RPM’s with the safety control bar in the feed position, as discussed on the previous page. -

Page 31: Shut-Down

The Chipping Cycle • Shut-down Shut-down Lock-up DANGER! After the machine is shut-down it is important for safety and security reasons to follow the lock-out procedure in the Safety section. The following components must be locked at the end of each work period: A rotating chipper drum may cause entanglement, crush, or mutilation of body parts resulting in serious injury or death. -

Page 32: Checklist

The Chipping Cycle • Checklist Now that you’ve become familiar with the entire chipping process, use the checklists below at the beginning and end of each cycle. Checklist Start-up Shut-down Emergency equipment is on the work site Safety control bar is in the neutral position At least two trained personnel are on the work site The ignition key is out of the machine and control panel is locked All personal are outfitted with proper protective clothing and... - Page 33 Features and Function Section 3 The Basics Right View ..........3.2 Left View.

-

Page 34: The Basics

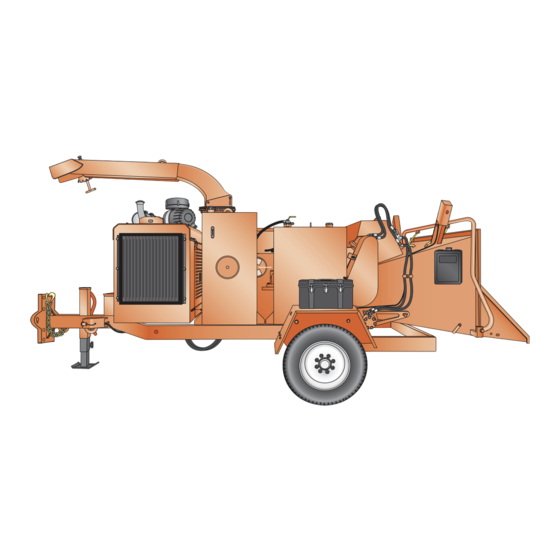

Features and Function • The Basics • Rght View The Basics Figure 3.1 Right View Safety control Auto reverse Manual swivel valve discharge crank Top feed wheel End view Valve bank Hood locking pin Yoke Air filter housing Safety cables Engine control panel Engine Yoke locking... - Page 35 Features and Function • The Basics • Rght View Safety control bar 12 . Battery box Controls forward, neutral and reverse action of the feed wheels.* Container where the battery is stored.* Valve bank 13 . Discharge locking pin Main controls needed to operate the chipper. These include; Locks discharge chute in position.

-

Page 36: Left View

Features and Function • The Basics • Left View Left View Figure 3.2 Fuel shut-off valve Adjustable Discharge deflect Hydraulic oil chute filter (located behind tank) Muffler Fuel and hydraulic oil gauges and filler cap Feed wheel chain guard Deflect handle Drum locking Manual holder... - Page 37 Features and Function • The Basics • Left View Adjustable deflect Flag holder Easily adjustable discharge deflect with four locking positions. Holds safety clearance flags. Discharge chute 10 . Tool box Used to change the direction of the discharge. Capable of 360º rotation.* Lockable container for electrical pin connector and other tools.* Muffler 11 .

-

Page 38: Components

Features and Function • Components • Infeed Components *Safety Control Bar Positions Forward Infeed pulls material into the feed wheels Figure 3.3 Neutral Neutral stops movement stops movement of the feed wheels of the feed wheels Reverse pushes material out of the feed wheels Safety control bar For emergency use only. - Page 39 Features and Function • Components • Infeed Safety When feeding material into the infeed, keep all body parts outside of the infeed chute. To safely accomplish this the material being fed should be no DANGER shorter than 4’ long. The brush being fed into the infeed should be no shorter than 4 ft. and no Movement or placement of any part of the body inside the wider than 65”.

-

Page 40: Infeed Options

Features and Function • Components • Infeed Options Infeed Options Figure 3.4 Spring Assist Folding Tray Rubber Infeed Curtain with Pulley Safety Cables Chipper with infeed guard, pulley system, folding Pulley system tray and emergency stop button options Infeed guard Safety cable pulley system... - Page 41 Features and Function • Components • Infeed Options Safety Rubber infeed curtain and Pulley Safety Cables: Pull the safety cables straight down to reverse the feed wheels. DANGER Spring Assist Folding Tray: The spring assist mechanism helps raise and lower the tray with ease. Lock the tray using the infeed tray Running the engine while a person is performing locking pins.

-

Page 42: Winch Option

Features and Function • Components • Winch Option Winch Option Figure 3.5 Winch Tension handle le a Winch brake l e a Winch cable Winch hook See decal for valve handle positions Infeed opening Safety control bar 3.10 76347-282 • 12-08... - Page 43 Features and Function • Components • Winch Options Safety Function The winch assists in moving heavy limbs or logs (Loads) to the infeed opening. DANGER Movement or placement of any part of To operate the winch: the body inside the infeed chute will result in dismemberment, mutilation, 1 .

-

Page 44: Feed Wheels And Chipper Drum

Features and Function • Components • Feed Wheels and Chipper Drum Feed Wheels and Chipper Drum Figure 3.6 Discharge chute Knife pocket Chipper drum Top feed wheel Anvil Chipper housing Bottom feed wheel 3.12 76347-282 • 12-08... - Page 45 Features and Function • Components • Feed Wheels and Chipper Drum Safety The feed wheel operates in two directions, forward and reverse. The safety control bar and the emergency cables located on the infeed control the DANGER direction of the feed wheels. When the chipper drum is moving the chipper hood MUST be closed and Movement or placement of any part of the body inside locked in place using the hood locking pins.

-

Page 46: Feed Wheel Options

Function Feed wheels: Each type of feed wheel grips the brush in a different way. Some feed wheels suit certain woods better than others. Morbark offers these optional feed wheels depending on your chipping preference. Drive guards: Are used to eliminate the danger of any clothing or body parts getting caught in the drive shafts of the feed wheels. -

Page 47: Feed Wheel Chain Drive

Features and Function • Components • Feed Wheel Drive Feed Wheel Chain Drive Safety DANGER Moving chains will cause serious injury or death. Do not operate without the guards in place. Do not attempt to touch, check, clean, or adjust the chain during operation. Function The feed wheel chain provides power to the top feed wheel. -

Page 48: Yoke

Features and Function • Components • Yoke Yoke Safety DANGER Movement or placement of any part of the body inside the yoke will result in mutilation, serious injury, or death. Keep all parts of the body (hands, feet, head) outside of the yoke. Function The yoke houses the top feed wheel, its primary function is to aid in feeding material into the chipper. -

Page 49: Valve Banks

Features and Function • Components • Valve Banks Valve Banks Safety WARNING Relieve stored hydraulic pressure before performing service to the hydraulic system. Components could be hot to the touch. Function The hydraulic valve bank controls operate the machine. They control the yoke and aide in machine maintenance. -

Page 50: Discharge Chute

Features and Function • Components • Discharge Chute Discharge Chute Figure 3.8 Adjustable deflect Deflect handle Discharge chute will rotate a complete adjusts to four 360º angles Discharge chute Height adjustment bolts and holes Manual swivel handle Chain Discharge locking pin Transition base 3.18 76347-282... - Page 51 Features and Function • Components • Discharge Chute To rotate the chute: Safety Pull down on the discharge locking pin. DANGER Manually position the discharge chute to point in the desired direction by rotating the manual swivel handle. The discharge Contact with the discharge chute while it’s in motion will chute will rotate a full 360º.

-

Page 52: Discharge Chute Options

Features and Function • Components • Discharge Chute Options Discharge Chute Options Figure 3.9 Discharge chute will rotate a complete Bottom Clean-out 360º To release the toggle clamp and open the front Side Clean-out panel, move the Side clean- handle down out cover Bottom clean-out cover... - Page 53 Features and Function • Components • Discharge Chute Options Safety Side Clean-out: Remove the bolts and cover. Clear out debris from WARNING chute. Place cover back on window and securely fasten with bolts. Bottom Clean-out: Release the toggle clamp and open the bottom Hydraulic fluid is under pressure.

-

Page 54: Discharge Chute Cleaning

Features and Function • Components • Discharge Chute Cleaning Discharge Chute Cleaning Safety To clean out the chute: DANGER Complete lockout/tagout. Inspect to make sure drum/disc has stopped turning. Never attempt to remove material by starting the machine and engaging the chipper to blow material out. This is a very dangerous and unsafe practice! Pull material out from the open end of the discharge. - Page 55 THIS PAGE INTENTIONALLY LEFT BLANK 76347-282 • 12-08 3.23...

-

Page 56: Hydraulic Oil And Fuel Tank

Features and Function • Components • Hydraulic Oil and Fuel Tank Hydraulic Oil and Fuel Tank Figure 3.10 Hydraulic oil Hydraulic oil filler cap vent cap Hydraulic oil filter located on the back side of the hydraulic tank Hydraulic oil sight gauge Fuel filler cap Fuel shut-off valve... - Page 57 Features and Function • Components • Hydraulic Oil and Fuel Tank Safety Each tank has a filter. The hydraulic oil filter is located on the side of the DANGER hydraulic oil tank. The fuel filter is locate in the engine enclosure. See your engine operator manual for more detail.

- Page 58 THIS PAGE INTENTIONALLY LEFT BLANK 3.26 76347-282 • 12-08...

-

Page 59: Engine Belt Drive

Features and Function • Components • Engine Belt Drive Engine Belt Drive Figure 3.11 Safety Belt guard door for WARNING checking belt tension Moving belts can cause serious injury or death. Do not operate without the guards in place. Do not attempt to touch, check, clean, or adjust the belts during operation. -

Page 60: Engine

Features and Function • Components • Engine Engine Figure 3.12 Typical Engine Configuration Right View Left View Air filter Muffler Control panel Note:”Panel will vary with engine make and Radiator screen model and is shown for (radiator is housed illustrative puposes only.” behind the screen) Engine housing Engine... - Page 61 Features and Function • Components • Engine Safety WARNING Loose clothing, long hair, dangling jewelry may get entangled in moving parts and cause serious injury. Do not get near or wear loose items near moving parts. The muffler becomes hot during operation. Contact with the muffler may cause burns.

-

Page 62: Hitch, Chains, And Jack

Features and Function • Components • Hitch, Chains, and Jack Hitch, Chains, and Jack Figure 3.13 Chipper should sit on a level surface with the machine parallel to the ground Wheel chocks 3.30 76347-282 • 12-08... - Page 63 Features and Function • Components • Hitch, Chains and Jack Safety When the chipper is attached to a towing vehicle: DANGER • The towing vehicle must be capable of handling your chipper • Park the vehicle and the chipper on a level surface Before operating always block the wheel, and ensure the chipper is on stable level ground when not attached to a •...

-

Page 64: Hitch And Jack Options

Features and Function • Components • Hitch, Chains, and Jack Options Hitch and Jack Options Actuator cable Figure 3.14 Ball assembly Hitch with Ball Safety Assembly Switch break-away WARNING A defective battery or electrical short can result in your brakes not working. -

Page 65: Battery

Features and Function • Components • Battery Battery Figure 3.15 Safety WARNING Battery acid can cause The battery generates explosive gas during severe burns. Wear protective gear when normal operation. handling the battery. Keep ignition sources Battery away at all times. NOTE Charging the battery with cables connected can damage the machines electronic system. -

Page 66: Loader Option

Features and Function • Components • Loader Option Loader Option Figure 3.16 Main boom Jib boom cylinder Loader mount Main boom cylinder Jib boom Rotobec Grapple Grapple Mount Yoke locking pin Rear stabilizers 3.34 76347-282 • 12-08... - Page 67 Features and Function • Components • Loader Option Safety Function DANGER The loader attachment is used to move wood, that cannot be moved manually, closer to the chipper. It may also be used to manipulate the Contact between the loader and power lines will cause wood into the infeed.

- Page 68 Features and Function • Components • Loader Option The joysticks at the operators seat and on the swinging door on the operators side of the machine control the loader and yoke. There is a standard configuration and a CAT and JOHN DEERE specific configuration of the controls. The standard joystick configuration operate the yoke and grapple as follows: Figure 3.18 Figure 3.17...

- Page 69 Features and Function • Components • Loader Option Figure 3.19 Figure 3.20 Left joystick Left joystick Right joystick Right joystick CAT Control Configuration: JOHN DEERE Control Configuration: NOTE: This does not affect the joystick buttons in any way. NOTE: This does not affect the joystick buttons in any way. The joystick on the left moves the loader and the jib: The joystick on the left moves the loader and the main boom: Pushing the joystick to the left will swing the loader to the left.

-

Page 70: Control Bar Actuator

Features and Function • Components • Control Bar Actuator Option Control Bar Actuator Option Figure 3.21 Safety DANGER SPOUT RIGHT LEFT STAB. UP STATUS RIGHT STAB. UP YOKE UP ENGINE STOP Movement or placement of any part of the body inside the infeed will result in dismemberment, mutilation, serious SPOUT LEFT LEFT STAB. - Page 71 Features and Function • Components • Remote Option Remote Control, Options Safety DANGER Figure 3.22 You must start machine and engage the feedwheels in Directs the flow of chips Raises and lowers the right to the right or left Status Light reverse, hit your reverse toggle on your remote to ensure stabilizer the feedwheels come to a stop.

- Page 72 Features and Function • Components • Tether Remote Option Tether Remote Control, Options Safety WARNING Figure 3.24 Improper operation of these controls can cause serious injury. Do not allow anyone to operate this equipment before completely reading the manual. Tether Harness Machine Harness When using the tether remote always stay within working radius and always point transmitter toward...

-

Page 73: Remote

Features and Function • Components Remote , Option Remote Control For Loader Figure 3.25 Safety WARNING Operates the discharge Operates the loader Operates right to left swing and jib boom as yoke up and When using the remote control always pay complete Shuts down down Operates the grapple... - Page 74 M18R Specifications Figure 3.26 114” 212” General Chipper Tank Capacities Dual & Tandem Options Length (dual) ..212 inches Length* ... . 212 inches Drum diameter .

- Page 75 General Maintenance Section 4 Maintenance Overview ........4.2 Air Filter .

-

Page 76: Maintenance Overview

General Maintenance • Overview Maintenance Overview Table 4.1 • Routine Maintenance Schedule Start 1000 Chipper Component Required Maintenance Complete machine Visual inspection (see Safety section) and clean machine Tongue Remove & inspect for cracks, replace if cracks are present Fasteners (except drum knife bolts) Assemble using Loc-Tite 242 (blue) Engine oil Maintain according to OEM manual... -

Page 77: Air Filter

General Maintenance • Air Filter Air Filter A clean air filter is critical to the performance of the chipper and the life Inspect the old filter for evidence of dust leakage and gasket sealing of the engine. Dirt inside the engine will ruin it. The filter should be problems. -

Page 78: Lubrication

General Maintenance • Lubrication Lubrication Lubricating the machine is vital to its operation. There are 57 points of Table 4.2 • Routine Lubrication Schedule lubrication on the machine. Number of Start Description locations hours hours Lubricate the grease points as outlined on the schedule below. Wheel axle (1) Note: The following maintenance intervals apply for normal operating conditions only. -

Page 79: Lubrication Points

General Maintenance • Lubrication Lubrications Points Figure 4.2 Discharge Chute Swivel and Crank Control Bar Chipper Drum Bearings Yoke Pivot Pin Yoke Cylinder Top Feed Wheel Bearings Jack Hand Crank Clutch Battery Box Bottom Feed Wheel Bearings Wheel Axle 76347-282 •... -

Page 80: Bolts & Torque

General Maintenance • Bolts & Torque Bolts & Torque Making sure that all the bolts are regularly checked and tightened to the • Do not use the torque values shown in this chart in place of those specified in other sections of the manual proper torque is critical. - Page 81 General Maintenance • Bolts & Torque Grade 8 - Coarse Thread Grade 8 - Fine Thread Size Clamp Load Plain Plated Size Clamp Load Plain Plated 1/4-28 (.250) 3,263 14 ft-lb 10 ft-lb 1/4-20 (.250) 2,850 12 ft-lb 9 ft-lb 5/16-24 (.3125) 5,113 27 ft-lb...

-

Page 82: Belt Tension

General Maintenance • Belt Tension Belt Tension Before adjusting the belt tension: DANGER Throttle the engine down and disengage the clutch. Shut off the engine, remove the key and conduct machine lockout. Moving belts and chipper drum can pinch body parts, Remove the belt guard. - Page 83 General Maintenance • Belt Tension Figure 4.4 Figure 4.5 Small 0’ ring Deflection Force Scale Turn the engine belt drive adjustment bolts until the belt is fairly tight. Measure the belt span length of the drive, and lay a straight edge across the drive (see Figure 4.4).

-

Page 84: Chipper Knives

Always maintain proper knife sharpness. It is important to follow these guidelines to ensure efficient chipping: • Use original Morbark Inc. knives with the correct steel composition and hardness. Immediately replace worn knives 4.10 76347-282 •... - Page 85 General Maintenance • Chipper Knives To Turn or Replace the Knives: WARNING Remove the four knife bolts. Clean debris from the knife and knife pocket with a wire brush. Sharp edges and flying debris may cause serious injury. Inspect the knife holder, knife bolt, and threads for wear or damage. Always wear protective gloves and goggles while maintaining Note: If the knife holder face has a groove worn more than a 1/4”...

- Page 86 General Maintenance • Chipper Knives Never grind the angle greater than 31°. becomes dull. Place the knife back onto the knife holder. Apply a light coat of anti- To Sharpen the Knife Edge: seize lubricant to the bolts and clamp. When sharpening the knife edge use proper grinding techniques (hand file, power belt sander with fine paper, or conventional knife grinder with coolant Slide the knife back (away from the anvil) against the knife bolts.

-

Page 87: Knife Babbitting

General Maintenance • Knife Babbitting Knife Babbitt Figure 4.11 Spacers WARNING Open flame can result in burns or serious injury. Never babbitt a knife that measures less than 3 1/2 inches in width. Always wear protective gloves and goggles while babbitting the knives. -

Page 88: Knife Holder

Straight edge Knife holder Use original Morbark Inc. equipment with the correct steel composition and hardness. • Use the correct hardware to mount the holder and maintain the correct torque to the bolt. Keep the knife pocket and holder clean and free of debris 4.14... - Page 89 THIS PAGE INTENTIONALLY LEFT BLANK 76347-282 • 12-08 4.15...

-

Page 90: Knife Anvil

General Maintenance • Knife Anvil Knife Anvil Before inspecting or maintaining the anvil: DANGER Raise the yoke and insert locking pin (see Lockout Procedure). Follow steps 1-4 in Chipping Cycle Section to shut-down the machine. Failure to lockout the machine (e.g. yoke, shut power off) Figure 4.16 will result in unexpected operation and cause serious injury or death. - Page 91 General Maintenance • Knife Anvil To Flip or Replace the Anvil: Tighten the bolts to 150 ft/lbs. Remove the six anvil bolts. Figure 4.19 Clean debris from the anvil and anvil clamp slots with a wire brush. If the anvil edge is rounded, flip to a new edge or replace. Anvil can be flipped 4 times.

-

Page 92: Chipper Flange Bearing

General Maintenance • Chipper Flange Bearing Chipper Flange Bearing Install the nut and washer. DANGER Tighten nut until it is snug against the bearing. Leave enough space to install the expansion ring in step 9. Performing maintenance with the power source ON may Install outer grease slinger. - Page 93 General Maintenance • Chipper Flange Bearing Table 4.5 • Internal Clearance Reduction Figure 4.20 Top bearing Reduction in Internal Shaft Diameter housing Clearance 2-7/16, 2-1/2, 2-11/16, 2-3/4 .0015/.0020 Inner grease slinger ring Bottom bearing housing Tapered sleeve Chipper drum Chipper drum Chipper drum Bearing housing...

-

Page 94: Hydraulics

General Maintenance • Hydraulics Hydraulics When conducting maintenance on the hydraulic system be cautious of leaks, hot components (pumps, motors, relief valves), and stored energy. Always follow safety warnings and procedures when conducting maintenance on the hydraulic system. WARNING Before Conducting Maintenance: Hydraulic oil will vaporize and potentially ignite resulting in •... -

Page 95: Hydraulic System Maintenance Schedule

General Maintenance • Hydraulics Under normal conditions hydraulic oil should be changed every 2000 Troubleshooting the hydraulic system involves talking with the operators, operating hours or yearly, which ever comes first. In more severe conditions it understanding the schematics, and inspection of the machine. After should be changed every 1000 hours or six months. -

Page 96: Hydraulic Pump Troubleshooting Guide

General Maintenance • Hydraulics Table 4.7 • Hydraulic Pump Troubleshooting Guide Symptom Possible Cause Corrective Action Noisy Pump Air in the system Tighten loose fittings. Replace cracked hoses and damaged parts. Maintain hydraulic oil level in tank. Keep 3/4 full. Cavitation (vacuum in pump) Open clogged or restricted intake line or plugged air vent in tank. -

Page 97: Engine

If you are unsure about the regulations in your area, check with local -55º -67º fire agencies before beginning work. Your Morbark dealer can provide infor- mation about a spark arrestor suitable for use with the power unit installed in this machine. -

Page 98: Fuel

General Maintenance • Fuel Fuel Fuel Specifications DANGER Use No. 2-D diesel fuel (reference ASTM D975) under normal operating conditions. In extremely cold conditions No. 1-D diesel fuel is Ignition sources (e.g: lit cigarettes, open flame, sparks, recommended. Refer to the engine OEM manual for specific information excessive heat) will ignite diesel fuel and result in burns regarding the type of fuel to use. -

Page 99: Tires

General Maintenance • Tires Tires Figure 4.22 WARNING Over inflated tires may cause a tire to explode and result in serious injury or death. Always maintain a safe Radial Tire distance away from the tire during inflation. Use a hose with a pressure gauge. -

Page 100: Chipper Troubleshooting Guide

General Maintenance • Troubleshooting Chart Table 4.8 • Chipper Troubleshooting Guide Problem Probable Cause Corrective Action Chipper will not feed properly Dull chipper knives Turn, sharpen, or replace knives Loose belts Check for proper belt tension Knives ground at incorrect angle Grind knives at 31°...

Need help?

Do you have a question about the BEEVER M18R and is the answer not in the manual?

Questions and answers

I need a part number for a starter for a MorBark Beaver Chipper M18r 2018 year Gas motor