Summary of Contents for Nicotra Gebhardt RZR Series

- Page 1 Operating Instructions, ATEX Centrifugal fans belt driven (Translation of the original) II 2G c IIB T3 BA-CFB-RZR-RER-ATEX 6.4 - 03/2015...

-

Page 2: Table Of Contents

English Contents 1. Revision Index ............................EN-2 2. About This Operating Manual ....................... EN-3 3. Designated Use ............................. EN-5 4. Safety ..............................EN-7 5. Product Description ..........................EN-11 6. Handling and Storage .......................... EN-14 7. Installation ............................EN-15 8. Electrical Connection ........................... EN-18 9. -

Page 3: About This Operating Manual

2. About This Operating Manual These operating instructions are an integral part of the centrifugal fan. Nicotra Gebhardt GmbH shall not accept any liability or provide any warranty cover for primary damage or secondary damage arising as a consequence of disregarding these operating instructions. - Page 4 English 2.4.2. Levels of Danger in Warning Signs Table 2-1: Levels of danger in warning signs Symbol / Danger Level Likelihood of Consequences of Occurrence Neglect Death, serious Imminent danger physical injury Danger Death, serious Potential danger physical injury Warning Potential danger Minor physical injury Caution...

-

Page 5: Designated Use

English 3. Designated Use 3.1. Operating Data / Maximum Ratings Risk of injury! Adhere to technical specifications and permissible limits. Caution For technical specifications reference should be made to the type plate, technical data sheet and technical catalogue! To be observed specially! ... - Page 6 English The results are: Bearings damage Vibration Corrosion damage Deformation Unbalancing Abrasion damage Caution Unauthorised operation No operation above the indicated rpm (see type plate, data sheet) No operation at rpm ranges with increased vibration (resonance) ...

-

Page 7: Safety

Before leaving the factory all the fans are inspected and sealed with a mark of conformity. Nevertheless, when operating roof fans supplied by Nicotra Gebhardt GmbH there can be a risk of death or injury for the user or third parties, and a risk of damage to the fan or other material assets. - Page 8 English 4.3. Safety Instructions 1. Use appropriate safeguards to prevent contact with rotating parts (shafts, impeller, etc.). 2. Protection devices are so selected so that sucking or falling-in of objects will be prevented. 3. After installation (and before electrical connection) immediately refit any guards which have been removed during installation.

- Page 9 Notes Unauthorised structural modifications may not be made to the centrifugal fan without the consent of Nicotra Gebhardt GmbH. Nicotra Gebhardt GmbH shall not accept liability for any damage arising as a result of said modifications. Use only genuine spare parts supplied by Nicotra Gebhardt GmbH.

- Page 10 English 4.9. Signs on the Fan Depending on the model, the type plate and the arrow indicating the direction of rotation are fitted to the housing or handle for high visibility. 4.9.1. Type Plate Fig. 4-1: Example type plate Only Example 4.9.2 Belt drive plate Fig.

-

Page 11: Product Description

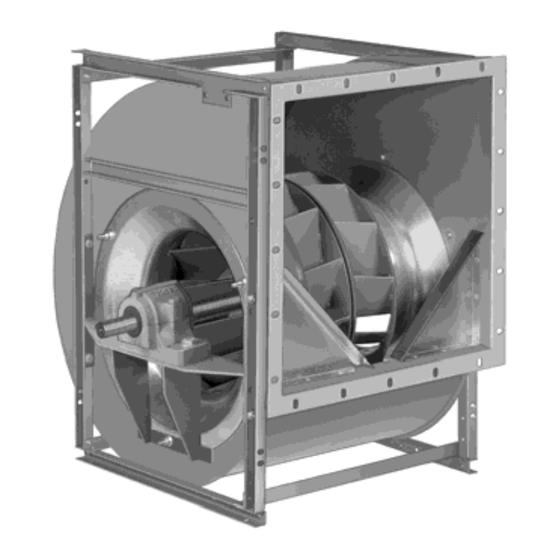

The centrifugal fans can be supplied completed as a fan set with base frame or pick-a-back, belt drive, and motor. If the fan is supplied by Nicotra Gebhardt as a bare fan i.e. without the necessary accessories, the ATEX conformity is limited to the fan itself as supplied. - Page 12 English 5.2.1 e.g. RZR 11– 1 Centrifugal fan 2 Base frame with - Motor rails -or - Motor slide bases 3 Pick-a-Back 4 Drive 7 Anti-vibration mounts Important Accessories: 5 Access door (if the impeller isn’t accessible) 6 Drain plug 8 Inlet guard 9 Discharge guard 10 Drive guard...

- Page 13 English 5.2.2 e.g. RER 11- 1 Centrifugal fan 2 Base frame with - Motor rails -or - Motor slide bases 3 Pick-a-Back 4 Belt drive 7 Anti-vibration mounts Important Accessories: 5 Access door ATEX- Scope of supply 6 Drain plug 8 Inlet guard 9 Discharge guard 10 Drive guard...

-

Page 14: Handling And Storage

English 6. Handling and Storage 6.1. Packing Centrifugal fans are packaged in sturdy cardboard boxes or on wooden crates depending on their size and weight. Instructions on removing transportation locks are enclosed. 6.2. Symbols on Packing The following symbols are printed on the cardboard boxes: Table 7-1: Symbols on packaging Symbol... -

Page 15: Installation

Observe the safety instructions and preventive measures in Chapter 4 and the relevant legal requirements. Caution The fan system supplied by Nicotra Gebhardt must not be modified in any way! It’s operation is exclusively permitted in it’s state as originally supplied and within the LIMITS SPECIFIED. - Page 16 English 7.3. Carrying out Installation 1. The fan or base frame must be fixed without stressing to the supporting structure. 2. AVM to be regularly placed around centre of gravity and definitely fixed. Check whether the AVM is evenly under load. No forces or vibrations may be transferred from other plant parts to ...

- Page 17 English RER 0200-2G / -3G RER 0225-2G / -3G RER 0250-2G / -3G RER 0280-2G / -3G RER 0315-2G / -3G RER 0355-2G / -3G RER 0400-2G / -3G RER 0450-2G / -3G RER 0500-2G / -3G RER 0560-2G / -3G RER 0630-2G / -3G RER 0710-2G / -3G RER 0800-2G / -3G...

-

Page 18: Electrical Connection

English 7.6. Install Protection Devices 1. Fit guards to protect exposed inlet openings (EN ISO 13857). 2. Design safety devices in such a way that they prevent objects from being sucked in or from falling in (see EN 60529). Electrical Connection 8.1. - Page 19 If plant conditions necessitate a direct start the suitability of the fan design must be confirmed with Nicotra Gebhardt. Fans with high inertia impellers can take over 6 seconds to reach top running speed. In these cases heavy duty motor protection relays or bimetal relays must be provided.

-

Page 20: Commissioning

9. Commissioning The motors are designed for continuous operation S1. If operations involve more than three starts per hour Nicotra Gebhardt GmbH shall be required to confirm the suitability of the motor. Potentially explosive gas mixtures in conjunction with hot and moving parts may cause serious or fatal injury. -

Page 21: Maintenance

English All the requisite safety devices to be installed. Prevent impeller from contact and from being hit by falling or sucked- in objects. The fan is not operated in a dusty environment. Ensure that unacceptable levels of dust are not allowed to gather on the fan. 9.2. - Page 22 English 10.2. Observing Regular Inspection Intervals In the interests of upkeep and safety we recommend having the operation and condition of the fans inspected at regular intervals by duly qualified service personnel or a professional maintenance firm and documenting these inspections.

- Page 23 In the case of bearing noise please contact Nicotra Gebhardt-Service for a check and a possible change of defective bearings. 10.4.3 Periods of stand still During longer periods of standstill the fan must from time to time be put into operation for a short while.

- Page 24 English 10.5.1 Tensioning rules for V-belt drives L = Span between shaft centres b = Belt deflection under test force F = Test force in N from the The correct tensioning for a belt is achieved if the individual test force F Fig.

-

Page 25: Disturbances

Fit and tension the belt in accordance with instructions. 10.5.6 Belt drive design If the belt drive is designed or modified without using the Nicotra Gebhardt selection programme the speed limits of the fan as well as the limitations for belt forces - to be found in the corresponding catalogue - are to respected. -

Page 26: Service, Spare Parts And Accessories

Germany www.nicotra-gebhardt.com 12.1. Ordering Spare Parts Use only genuine spare parts supplied by Nicotra Gebhardt GmbH as featured in the list of spare parts. The use of spare parts supplied by other manufacturers may compromise the safety of the equipment. Nicotra Gebhardt GmbH shall not accept any liability... - Page 27 If in the case of normal wear and tear a bearing change is required ask for the Nicotra Gebhardt-Service. 13.2.2 Bearings with Lubricating Device IWN 01 – Stand grease IWN 11 –...

- Page 28 English RZR 11- 0200·/.0710 Cast iron housing with struts and self aligning radial insert ball RZR 12- 0200·/.0710 bearings RZR 19- 0200·/.0355 with lubrication device IWN Fig. 13-5: Ball bearings in cast iron housing with struts Relubrication at least once a year. Interval to be reduced for heavy duty operation Grease Quantity: Press grease into bearing until fresh grease is escaping.

- Page 29 English RZR 13-0400·/.1000 Split type plummer block housing with self-aligning double row RZR 18-0400·/.1000 bearings RZR 13-1120./.1600 with lubrication device IWN Fig. 13-4: Self aligning double row bearing in a Plummer block housing Relubrication at least once a year. Interval to be reduced for heavy duty operation RZR 13 / 18- 0400-0500 0560-0630 0710-0800...

-

Page 30: Ec Declaration Of Conformity To Ec Council Directive 94/9/Ec (Atex 95

English EC Declaration of Conformity to EC Council Directive 94/9/EC (ATEX 95) We herewith declare that the machinery designated below, on the basis of its design and construction in the form brought onto the market by us is in accordance with the relevant safety and health requirements of the EC Council Directive as mentioned below. -

Page 31: Ec-Declaration Of Incorporation

English EC-Declaration of Incorporation The manufacturer: NICOTRA Gebhardt GmbH, Gebhardtstrasse 19-25, D-74638 Waldenburg, Germany herewith declares, that the following product: Product designation: Centrifugal fan Type nomination: RZR / RER .. -2G Serial n°: see type plate Year of manufacture: see type plate qualifies as a partly completed machine, according to Article 2, clause “g”... - Page 32 English Nicotra Gebhardt GmbH Gebhardtstrasse 19-25 74638 Waldenburg Germany Telefon +49 (0)7942 1010 Telefax +49 (0)7942 101170 E-Mail info@nicotra-gebhardt.com www.nicotra-gebhardt.com EN-32/32...

Need help?

Do you have a question about the RZR Series and is the answer not in the manual?

Questions and answers