Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Spectron spectrotec BU43F-AC-2U

- Page 1 User manual Pressure control panel BU43F-AC-2U 12/2020...

-

Page 2: Table Of Contents

Contents Spectron Gas Control Systems GmbH Contents 1 Introduction ..............................2 Description..............................2.1 Intended use ............................2.2 Misuse..............................2.3 Identification / label ..........................2.4 Environment ............................2.4.1 Temperatures..........................2.4.2 Degree of cleanliness ........................ 2.4.3 Emissions........................... 2.5 Standards and laws..........................3 Safety................................ - Page 3 Spectron Gas Control Systems GmbH Contents 9.2 Troubleshooting and fault rectification ....................27 10 Decommissioning and recommissioning ....................28 10.1 Decommissioning..........................28 10.2 Recommissioning..........................28 11 Dismantling and disposal........................... 29 11.1 General information on dismantling ...................... 29 11.2 Returns..............................29 11.3 Disposal ..............................

-

Page 4: Introduction

This user manual is the original user manual for the Pressure control panel BU43FAC-2U from Spectron Gas Control Systems GmbH, referred to as Spectron. The user manual is intended to facilitate correct and safe operation for the operating firm, and to warn against misuse. -

Page 5: Description

Spectron Gas Control Systems GmbH Description | 2 2 Description 2.1 Intended use The intended use of the Pressure control panel BU43FAC-2U is the expansion of a gas from a gas source and the distribution of the gas with adjustable outlet pressure. -

Page 6: Environment

2 | Description Spectron Gas Control Systems GmbH Project number PROJECT Article description BU43FAC-2U-0-SSE-M-SV-F5-KH2 Inlet pressure P1 25 bar Outlet pressure P2 1.5 bar Gas type Acetylene (C Flow rate Qmax 150 m Temperature range -20 … +60°C Pcheck test pressure 25 bar 2.4 Environment... - Page 7 Spectron Gas Control Systems GmbH Description | 2 ProdSG Produktsicherheitsgesetz (Product Safety Law) GefStoffV Gefahrstoffverordnung (Hazardous Substances Ordinance) TRGS 400, 407, 500, 720, 721, 722, 727, Technische Regeln Betriebssicherheit (Tech- 745,746 nical Regulations on Operational Safety) TRBS 1111, 2152, 3145, 3146...

-

Page 8: Safety

3 | Safety Spectron Gas Control Systems GmbH 3 Safety 3.1 Basic information on the safety instructions The product complies with the recognised technical regulations. Nevertheless, knowledge of the media used and their dangers as well as basic knowledge of the pressure control panel are pre- requisites for safe and accident-free operation. -

Page 9: Safety Instructions

Spectron Gas Control Systems GmbH Safety | 3 3.2 Safety instructions The safety instructions are to be observed by all persons working on the system. The rules and regulations for accident prevention applicable to the place of use are to be observed. The in- struction of the operating and maintenance personnel on system safety must be documented. - Page 10 3 | Safety Spectron Gas Control Systems GmbH WARNING Repairs If the product is not used as intended, unpredictable operating conditions may occur. Serious personal injuries are possible. a) Repairs may not lead to a change in function. The system may not be tampered with or modified.

-

Page 11: Emergencies And Safety Devices

Spectron Gas Control Systems GmbH Safety | 3 NOTICE Transportation Persons may be injured while transporting the product. a) Always use suitable lifting equipment when lifting and moving heavy loads and ensure that the transport is secured correctly. NOTICE Lighting Incorrect switching actions or confusion can occur due to inadequate lighting. -

Page 12: Qualification Of The Operating And Maintenance Personnel

3 | Safety Spectron Gas Control Systems GmbH 3.4 Qualification of the operating and maintenance personnel The intended user group is the system operator (user of the system) and the system mainten- ance personnel. Every person working on the system must be familiar with the functions and dangers associated with the overall system. -

Page 13: Design And Function

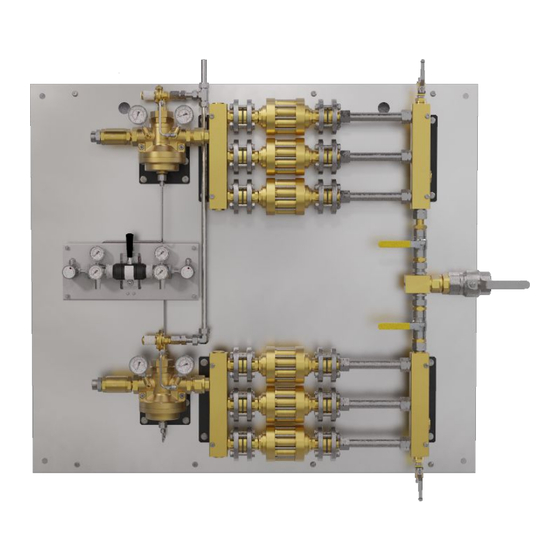

Spectron Gas Control Systems GmbH Design and function | 4 4 Design and function 4.1 Design Illustration of the pressure control panel with gas cylinder connected Illustration 1: BU43F-AC-2U design Pos. Description Short name Connection High pressure inlet G ¾" LH external... - Page 14 4 | Design and function Spectron Gas Control Systems GmbH Label Over-pressure valve SV73 Control pressure connection 6 mm compression fit- ting Pilot pressure regulator Waste gas shut-off valve M16x1.5 external GES_BU43F-AC-2U_1220...

-

Page 15: Functional Description

Spectron Gas Control Systems GmbH Design and function | 4 4.2 Functional description Waste gas Waste gas Process gas Process gas Waste gas Waste gas Process gas Waste gas Illustration 2: P&ID BU43F-AC-2U The intended use of the Pressure control panel BU43FAC-2U is the expansion of a gas from a gas source and the distribution of the gas with adjustable outlet pressure. -

Page 16: Technical Data

(incl. power supply) are the connec- tions on the pressure control panel or product. The following areas and functions have not been included in the scope of supply from Spectron: – other systems, lines and installations of the overall system –... -

Page 17: Installation

Spectron Gas Control Systems GmbH Installation | 5 5 Installation 5.1 General information CAUTION Injury or damage in the event of incorrect assembly or disassembly Special steps are required for assembly and disassembly work on the product. Personal injuries and damage to the product are possible. - Page 18 5 | Installation Spectron Gas Control Systems GmbH 1. Open valve PGI to build up pressure in the system (1.5 bar). 2. Wait until the pressure has been built up and close the PGI valve. 3. Check whether the displays on PG P1 and PG P2 are identical. If the values do not match, check the pressure regulator setting and readjust via the pilot pressure if necessary.

-

Page 19: Commissioning

Spectron Gas Control Systems GmbH Commissioning | 6 6 Commissioning 6.1 Preparations for commissioning The commissioning of the pressure control panel may only be carried out after the integration into the inventory has been completed. Commissioning is not permitted until the incomplete ma- chine has been installed into a complete machine and this corresponds to the provisions of the EU Machinery Directive and the EC Declaration of Conformity according to appendix II A. -

Page 20: Operation

7 | Operation Spectron Gas Control Systems GmbH 7 Operation 7.1 General information on operation During regular operation, the system will be in supply mode. The procedure for decommissioning and recommissioning for extended system standstills is de- scribed in the "Decommissioning and recommissioning [} 28]" chapter. - Page 21 Spectron Gas Control Systems GmbH Operation | 7 With each exchange of the gas source, check the connection for leaks. We strongly recommend replacing the sealing every time the gas source is exchanged. Always turn the shut-off valves slowly and as far as the stop when opening or closing them! Changing the supply side 1.

- Page 22 7 | Operation Spectron Gas Control Systems GmbH The pressure control panel is ready for supply. GES_BU43F-AC-2U_1220...

-

Page 23: Maintenance, Cleaning And Repairs

Spectron Gas Control Systems GmbH Maintenance, cleaning and repairs | 8 8 Maintenance, cleaning and repairs 8.1 General information on maintenance WARNING Noise emission When working on pressurised pneumatic supply, significant noise emission can occur. Acute and chronic loss of hearing may result. -

Page 24: Flushing The Process Gas Into The Control Panel

8 | Maintenance, cleaning and repairs Spectron Gas Control Systems GmbH CAUTION Injury or damage in the event of incorrect assembly or disassembly Special steps are required for assembly and disassembly work on the product. Personal injuries and damage to the product are possible. - Page 25 Spectron Gas Control Systems GmbH Maintenance, cleaning and repairs | 8 Components Test Interval Filter Replace filter Replacement with insufficient flow rate Visual inspection for corrosion, At least annually and before each damage and correct fastening Func- commissioning process tional test...

-

Page 26: Repair

9 | Repair Spectron Gas Control Systems GmbH 9 Repair 9.1 General information on repair work WARNING Noise emission When working on pressurised pneumatic supply, significant noise emission can occur. Acute and chronic loss of hearing may result. a) Never perform work on the pressurised pneumatic supply without hearing protection. -

Page 27: Troubleshooting And Fault Rectification

Spectron Gas Control Systems GmbH Repair | 9 · Detect and assess the causes of the malfunction · Rectify faults and restore operational readiness Repairs to the product may only be performed by the manufacturer or specialist personnel in- structed on the system. -

Page 28: Decommissioning And Recommissioning

10 | Decommissioning and recommissioning Spectron Gas Control Systems GmbH 10 Decommissioning and recommissioning 10.1 Decommissioning The gas supply via the Pressure control panel can be interrupted without additional risks. No special maintenance or preservation work is required during this time. -

Page 29: Dismantling And Disposal

6. Pack the product. 11.2 Returns If products are returned to Spectron for checking, maintenance or repair, it is essential to purge them with inert gas. A check can only be undertaken by Spectron if the repair pre-registration including the decontamination declaration has been duly completed. -

Page 30: Disposal

11 | Dismantling and disposal Spectron Gas Control Systems GmbH 11.3 Disposal Dismantling and disposal must be carried out in accordance with the official and legal require- ments at the site of the system. The operator must produce a risk assessment and work instruc- tions before dismantling. - Page 31 Spectron Gas Control Systems GmbH Monzastr. 2c D-63225 Langen Tel: +49 (0)6103 9424-050 Fax: +49 (0)6103 9424-072 info@spectron.de www.spectron.de...

Need help?

Do you have a question about the spectrotec BU43F-AC-2U and is the answer not in the manual?

Questions and answers