Summary of Contents for Harvard Apparatus BTX HT

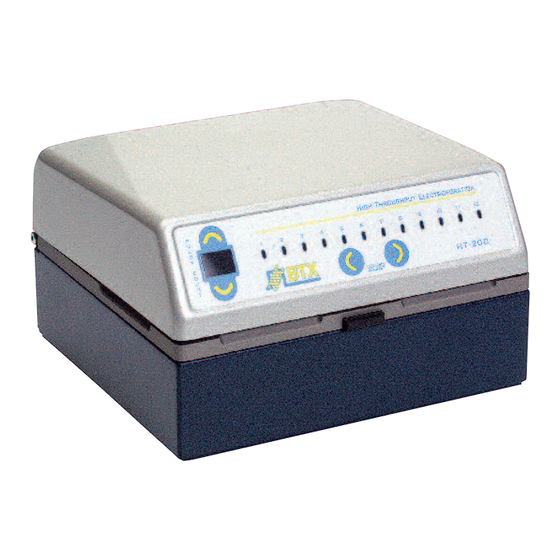

- Page 1 User’s Manual HT 96-Well Electoporation System Model HT-200 & HT-100 Plate Handler MA1 45-0400 Model HT-100 MA1 45-0401 Model HT-200 Publication 5500-001-REV-F...

- Page 2 WEEE/RoHS Compliance Statement EU Directives WEEE and RoHS To Our Valued Customers: We are committed to being a good corporate citizen. As part of that commitment, we strive to maintain an environmentally conscious manufacturing operation. The European Union (EU) has enacted two Directives, the first on product recycling (Waste Electrical and Electronic Equipment, WEEE) and the second limiting the use of certain substances (Restriction on the use of Hazardous Substances, RoHS).

-

Page 3: Table Of Contents

Model HT-200 & HT-100 Plate Handler Table of Contents General Information: Models ................2 Serial Numbers ..............2 Calibrations ..............2 Warranty ..............2-3 General Safety Summary..........4-5 Introduction ..............5 Electrical & Technical Specifications ......6 Operating Basics: Model HT-200 Plate Handler........8-9 Model HT-100 Plate Handler ........10-11 Advacned Operation: Programming: HT 96-WELL 25 Set-Up ..........12 HT 96-WELL 96 Set-Up ..........13... -

Page 4: General Information

Warranty Harvard Apparatus warranties these BTX Plate Handlers for a period of 2 years from date of purchase. At its option, Harvard Apparatus will repair or replace the unit if it is found to be defective as to workmanship or material. - Page 5 Model HT-200 & HT-100 Plate Handler General Information (continued) replacement and return. If the unit is replaced, the replacement unit is covered only for the remainder of the original warranty period dating from the purchase of the original device. This warranty gives you specific rights, and you may also have other rights which vary from state to state IMPORTANT: Read all Instructions, Warnings and Precautions prior to use.

-

Page 6: General Safety Summary

DO NOT OPERATE WITH SUSPECTED FAILURES If you suspect there is damage to the product, have it inspected by qualified Harvard Apparatus service personnel. FIRE OR SHOCK HAZARD Observe all ratings and markings on the product or in the manual before using the device. -

Page 7: Introduction

Model HT-200 & HT-100 Plate Handler General Safety Summary (Continued) Safety Terms and Symbols: TERMS THAT APPEAR IN THIS MANUAL: WARNING. Warning statements identify conditions or practices that could result in injury or loss of life. CAUTION. Caution statements identify conditions or practices that could result in damage to these products or other property. -

Page 8: Electrical & Technical Specifications

Model HT-200 & HT-100 Plate Handler Electrical & Technical Specifications Standard Capabilities: Power 100 to 240 VAC, 50/60 Hz, 15 W, 0.50 A fuse (2) Voltage Range 0 to 3000V DC (Pulse Input) Pulse Length Range 10 µsec to 10 sec 1 to 99 Pulse Number Range Operating Temperature... -

Page 9: Operating Basics

Model HT-200 & HT-100 Plate Handler Operating Basics WARNING HIGH VOLTAGE Make sure the BTX electroporator is switched off before continuing. CAUTION Do not use highly conductive solutions when the electroporator is in high voltage mode (>500V). Front of the HT-200 Plate Handler Column Adjust Colum n LED’s... -

Page 10: Model Ht-200 Plate Handler

Model HT-200 & HT-100 Plate Handler Operating Basics (continued) Model HT-200 Plate Handler 1. Select a plate size a. Select 4 mm or 2 mm gap plate. For example, if currently using 4 mm cuvettes use a 4 mm plate i. - Page 11 Model HT-200 & HT-100 Plate Handler Operating Basics (continued) 8. Configure the electroporator with the appropriate settings for voltage, pulse length, pulse interval and pulse number. For the ECM 830 Generator (ECM 630 is a single pulse Generator and this does not apply) *a.

-

Page 12: Model Ht-100 Plate Handler

Model HT-200 & HT-100 Plate Handler Operating Basics (continued) Model HT-100 Plate Handler 1. Select a plate size a. Select 4mm or 2mm gap plate. For example if currently using 4 mm cuvettes use a 4 mm plate i. The plate size should be selected according to the electric field desired, the desired volume of the sample, and the capabilities of the electroporator. - Page 13 Model HT-200 & HT-100 Plate Handler Operating Basics (continued) 7. Configure the electroporator with appropriate electrical settings. For ECM 630 Generators (voltage, resistance and capacitance) a. Press pulse on the electroporator to initiate the pulse for that column, the plate handler will beep. b.

-

Page 14: Advacned Operation: Programming: Ht 96-Well 25 Set-Up

Model HT-200 & HT-100 Plate Handler Advanced Operation: Programming HT 25 Set-Up 1. Ensure the unit is unplugged and disconnected from the generator. 2. Open the lid of the unit. 3. Please remove the pins from the first five spaces (blue) into the middle five spaces (red) using green pliers provided or if you do no have them use standard needle nose pliers. -

Page 15: Ht 96-Well 96 Set-Up

Model HT-200 & HT-100 Plate Handler Advanced Operation: Programming (continued) HT 96 Set-Up 1. Ensure the unit is unplugged and disconnected from generator. 2. Open the lid of the unit. 3. Install pogo pins into the locations shown in red using the liers provided or use standard needle nose pliers, taking care not to damage the gold plating on the head of the pin. -

Page 16: Appendix A: Troubleshooting

No energy is delivered to the plate in this mode. Please contact Harvard Apparatus, BTX Technical Service at any of the numbers listed on the following page in the event of any failure. -

Page 17: Appendix B: Maintenance

Model HT-200 & HT-100 Plate Handler Appendix B: Maintenance WARNING Do not attempt maintenance while the Plate Handler is plugged into an electroporator. Clean the Plate Handler body with a soft cloth or tissue. If necessary, moisten the cloth or tissue with a dilute detergent or alcohol solution. •... -

Page 18: Appendix C: Accessories & Replacement Parts

Model HT-200 & HT-100 Plate Handler Appendix C: Accessories and Replacement Parts Part Number Description 45-0411 HT 25/200 System Includes ECM ® 830, HT-200 Plate Handler, (6) HT 25 Electroporation Plates 45-0421 HT 96/200 System Includes ECM ® 830, HT-200 Plate Handler, (2) 96 well plates 45-0422 HT 96/100 System Includes ECM ®... - Page 19 84 October Hill Road • Holliston MA, 01746 508.893.8999 Phone: 800.272.2775 (U.S. Only) Toll Free: 508.429.5732 Fax: techsupport.btx@harvardapparatus.com E-mail: www.btxonline.com Web:...

Need help?

Do you have a question about the BTX HT and is the answer not in the manual?

Questions and answers