Advertisement

Quick Links

DHC-500 Gen 2

Quick Cal & Troubleshooting Guide

General

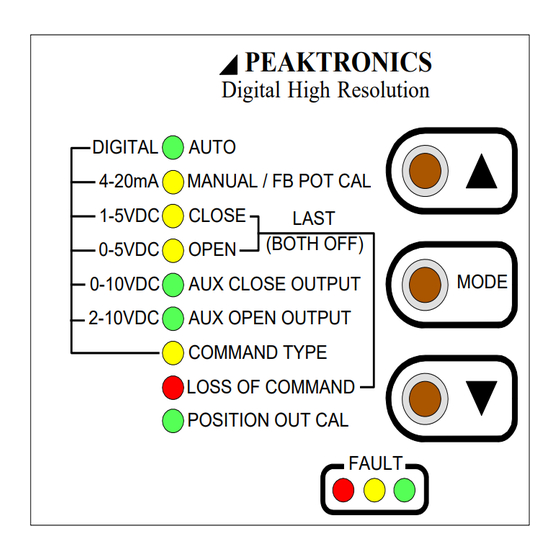

The MODE button selects a particular function, or mode, and the indicator for the selected mode turns on solid. Pushing

the MODE button saves any new setting of the current mode before switching to the next mode. The adjust up (▲) and

adjust down (▼) buttons are used to make adjustments to current mode. For more details regarding calibration and fea-

tures refer to the manual.

1. Use the mechanical override to move the actuator to a mid-stroke position to allow for safe electrical operation of

the actuator while determining actuator rotation. If the actuator is outfitted with a local/remote station, select the

remote mode. CAUTION! Incorrect actuator rotation can cause damage to the actuator and/or valve.

2. To test the actuator rotation, apply 3-phase power with earth ground and verify that the DHC-500 is in the "Manual

Mode", and that the yellow "MANUAL/FB POT CAL" LED is illuminated. If not, immediately push the mode

button as required until the LED is illuminated (actuator will stop rotation in this mode). The LED may be flashing

(at different speeds) through the next several steps. This is expected and be will be explained.

3. Press the adjust up (▲) button to confirm that the actuator moves toward open as shown in "Direct Acting" above. If

not, turn all power off, reverse L1 and L2 power connections, and retest for correct actuator rotation.

4. Use the adjust buttons (▲ and ▼) to move the actuator and verify that the limit switches are set past the desired

open and closed positions, but not so far as to interfere with the mechanical end stops, if the actuator has this fea-

ture. Then move the actuator to mid stroke.

5. If LED is solid, proceed to step 7.

6. If LED is flashing, loosen the gear on the actuator shaft and rotate the potentiometer gear until the LED is no longer

flashing, but on solid - this indicates the center of the potentiometer's travel. Note that the LED will flash at a

slower rate the farther away from the mid position it gets. Once the LED is on solid tighten the actuator shaft gear

and ensure that the gear engagement is tight and properly meshed.

PEAKTRONICS, Inc.

Quick Calibration Procedure

PEAKTRONICS

Digital High Resolution

DIGITAL

AUTO

4-20mA

MANUAL / FB POT CAL

1-5VDC

CLOSE

LAST

(BOTH OFF)

0-5VDC

OPEN

0-10VDC

AUX CLOSE OUTPUT

2-10VDC

AUX OPEN OUTPUT

COMMAND TYPE

LOSS OF COMMAND

POSITION OUT CAL

www.peaktronics.com

1363 Anderson

Clawson, MI 48017

MODE

FAULT

Phone (248) 542-5640

REFERENCE ROTATIONS

OPEN

actuator motion

DIRECT ACTING

OPEN

actuator motion

REVERSE ACTING

sales@peaktronics.com

page

1 of 4

800-220A

Advertisement

Summary of Contents for Peaktronics DHC-500 Gen 2

- Page 1 DHC-500 Gen 2 page 1 of 4 Quick Cal & Troubleshooting Guide Quick Calibration Procedure General The MODE button selects a particular function, or mode, and the indicator for the selected mode turns on solid. Pushing the MODE button saves any new setting of the current mode before switching to the next mode. The adjust up (▲) and adjust down (▼) buttons are used to make adjustments to current mode.

- Page 2 DHC-500 Gen 2 page 2 of 4 Quick Cal & Troubleshooting Guide 7. Push the MODE button until the “CLOSE” LED is lit solid. Use the adjust down (▼) button to drive the actuator completely closed so that the associated limit switch trips. Then tap the adjust up (▲) button to move the actuator just off the limit switch to the desired valve closed position.

- Page 3 DHC-500 Gen 2 page 3 of 4 Quick Cal & Troubleshooting Guide FAULT INDICATORS The DHC-500 detects various fault conditions that The table below provides a summary of the Fault indications. prohibit the unit from controlling the actuator. A combination...

- Page 4 DHC-500 Gen 2 page 4 of 4 Quick Cal & Troubleshooting Guide PROBLEM POSSIBLE CAUSES REMEDIES Actuator or valve is mounted incor- Remount actuator as necessary. rectly on coupling. Actuator rotates valve backwards. Actuator needs to be reverse acting. Refer to "Close" and "Open" modes in manual.

Need help?

Do you have a question about the DHC-500 Gen 2 and is the answer not in the manual?

Questions and answers