Summary of Contents for SteelMax MBS 4

- Page 1 MBS 4 BAND SAW INSTRUCTION 【Read through this manual carefully before using the machine】...

-

Page 2: Table Of Contents

MBS 4 BANDSAW Thank you for choosing the Steelmax MBS 4 Bandsaw. *This Instruction manual must be retained by the user of this machine. Read this manual thoroughly to understand the usage, capacity, cautions, and simple repairs that ensure the proper operation of this bandsaw. -

Page 3: Operating Instructions

MBS 4 BANDSAW OPERATING INSTRUCTIONS ● Please observe “OPERATING INSTRUCTIONS” to prevent fire, electric shock or injury. ● Before using, please obtain understanding of all the contents of “OPERATING INSTRUCTIONS” and adhere to the instructions. ● After reading this manual, please keep it easily accessible for reference and use. - Page 4 MBS 4 BANDSAW WARNING -Wear caps or protective hair covering to contain long hair to reduce the danger of being caught in moving parts. -When not using, servicing, cleaning, checking or replacing parts, turn off and unplug the machine. If the machine remains plugged in, it may start suddenly, leading to accident or injury.

- Page 5 MBS 4 BANDSAW CAUTION -Watch the position of your fingers while lowering frame to avoid pinching of fingers. -Do not leave the machine with a long workpiece set on it. You may tumble and get injured. -Securely install accessories in accordance with this manual. Otherwise, accident or injury may result.

-

Page 6: Components Of The Machine

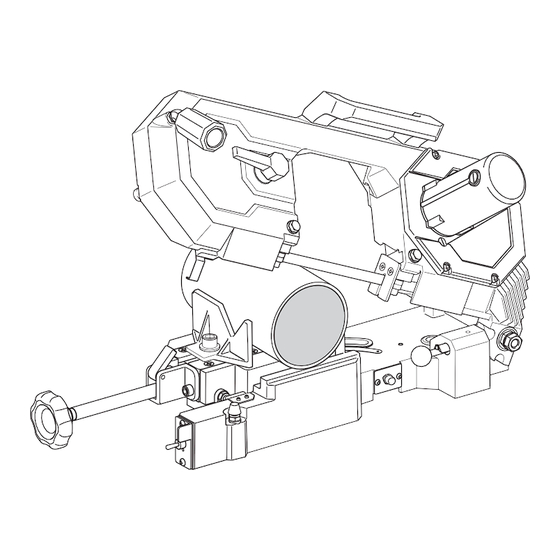

MBS 4 BANDSAW COMPONENTS OF THE MACHINE Tension Handle Motor Handle Frame Clamp Handle Switch Stopper Pin Blade Guide R Stop Bolt Overload Switch Blade Guide F Saw Blade Back Plate Clamp Lever... -

Page 7: Specifications

MBS 4 BANDSAW Item MBS 4 Bandsaw φ4.72" (120 ㎜) Round Square □ 4.0" (100 ㎜) ° Cutting Round φ2.0" (50 ㎜) Capacity Square □ 2.0" (50 ㎜) ° No Load 279' (85m)/min (50/60Hz) Blade speed Cutting 180' (55 m)/min (50/60Hz) -

Page 8: Saw Blade Selection Chart

MBS 4 BANDSAW Under 1.1/4" 〇 Steel Pipe 1.1/2"~2.1/2" 〇 〇 (Size) 3"~4" 〇 Thin wall 〇 Conduit Pipe Thick wall 〇 Under 3.9 〇 Shaped Steel & Rods 4.0~4.9 〇 〇 (Thickness, mm) 5.0~ 〇 ~3.9 〇 Stainless Steel Pipe (Thickness, mm)... - Page 9 MBS 4 BANDSAW...

-

Page 10: Installation

MBS 4 BANDSAW INSTALLATION Carrying the Machine WARNING -When lifting the machine, bend your knees to avoid a load on your waist. -The machine with chip is slippery. Do not drop the machine while lifting it. Installation DANGER -Always ground the machine to avoid electric shock or resultant death. - Page 11 MBS 4 BANDSAW *1 Confirmation of Earth (Grounding) and Earth Leakage Circuit Breaker Before starting use of the machine, make sure that the power supply to which this machine will be connected is fitted with an earth leakage circuit breaker for prevention of electric shock (earth leakage circuit breaker) which conforms to the occupational safety and health law, electrical equipment technical standard, etc.

-

Page 12: Operation

MBS 4 BANDSAW OPERATION Preparing for Operation CAUTION -Select a suitable Saw Blade for the workpiece, referring to Saw Blade Selection Chart. -Do not turn on the machine while Saw Blade is put on the workpiece. because this might cause the machine to experience failure -When cutting , Lower Saw Blade to the workpiece after Saw Blade has fully rotated. -

Page 13: Setting A Workpiece

MBS 4 BANDSAW Setting a Workpiece 1. Pull out Frame to 90° and fix the Stopper Pin 90° position with Stopper Pin. Lock Workpiece On Vice 2. Place a workpiece on the vise surface in a stable position. Feed Screw Guide Tilt it 3. -

Page 14: Miter Cutting

MBS 4 BANDSAW Miter Cutting 1. Turn Clamp Lever counterclockwise to Clamp Lever loosen the vise part. Loosen Clamp Lever 2. Turn the vise part to the desired angle Tighten and fix the position by turning Clamp Lever clockwise. Desired angle... -

Page 15: Cutting

MBS 4 BANDSAW Cutting 1. Pull out Stopper Pin and unlock Frame. Stopper Pin Un Lock 2. Turn on the machine and check that Blade is rotating smoothly. Lower Frame and place Saw Blade on the workpiece. When miter cutting, hold Frame for a while until Saw Blade gets into the workpiece and stable. -

Page 16: Removing Workpiece

MBS 4 BANDSAW Removing Workpiece 1. After cutting, raise Frame to 90° and Stopper Pin 90° Lock lock it with Stopper Pin. 2. Loosen Clamp Handle and remove the Clamp Handle Loosen workpiece. CAUTION -Immediately after cutting, cut surfaces are hot. Do not touch them with bare hands. -

Page 17: Cleaning After Use

MBS 4 BANDSAW Cleaning After Use WARNING -Do not blow off chips using compressed air. They may get into eyes and loss of eyesight may result. -Chips are sharp. Do not touch them with bare hands. Always wear gloves. Remove chips scattered on the machine or in the area. -

Page 18: Maintenance & Inspection

MBS 4 BANDSAW MAINTENANCE & INSPECTION Replacing Saw Blade WARNING -Before replacing Saw Blade, always unplug the machine. The machine may start suddenly, it may lead to injury. -When opening Back Plate, be careful with Saw Blade which may spring out of the machine. - Page 19 MBS 4 BANDSAW 3. Open Back Plate and remove Saw Blade in the order D → C → B → A as the drawing. Remove 4. Install a new Saw Blade in the order A → B → C → D as the drawing.

-

Page 20: Replacing Pully Rubber

MBS 4 BANDSAW Replacing Pulley Rubber WARNING -Before replacing Pulley Rubber, always unplug the machine. The machine may start suddenly, it may lead to an accident or injury. -When opening Back Plate, be careful with Saw Blade which may spring out of the machine. -

Page 21: Replacing Carbon Brush

MBS 4 BANDSAW Replacing Carbon Brush WARNING Unplug the machine to avoid electric shock. CAUTION Do not get oil, chips, etc. on the new Carbon Brush. Do not get dirt of gloves, etc. on the new Carbon Brush. Motor has Carbon Brushes, which are Brush Cap consumable parts. -

Page 22: Daily Inspection And Maintenance

MBS 4 BANDSAW Daily Inspection and Maintenance CAUTION Do not wet Motor with water. -If Power Plug, Power Cord or the extension cord is damaged, replace it immediately. -Check if Saw Blade chipped or damaged. If Saw Blade is chipped or damaged, replace Saw Blade. -

Page 23: Before Asking For Repairs

MBS 4 BANDSAW BEFORE ASKING FOR REPAIRS Trouble Possible Cause Solution When a new Saw Blade is used, it is liable to cut obliquely and test cuts must be required. Once oblique cutting occurred, it easily Test cuts are not enough. - Page 24 MBS 4 BANDSAW Trouble Possible Cause Solution Saw Blade is chipped. Replace the Saw Blade. Vibration Improper Tension Handle Turn Tension Handle clockwise fully. during setting. cutting Back Plate is not closed Attach Back Plate correctly. correctly. Select Saw Blade matched the workpiece.

-

Page 25: Electrical Wiring Diagram

MBS 4 BANDSAW ELECTRICAL WIRING DIAGRAM Overload... - Page 26 MBS 4 BANDSAW...

- Page 27 MBS 4 BANDSAW ● Customer Memo Please fill in for your record in the future. The information is helpful for inquiry and ordering parts. Products Number: Date Purchased: Store Purchased the Unit:...

- Page 28 Corporate Offices Sales@Steelmax.com | 303-609-9146 801 W. Mineral Ave. Suite 103, Littleton CO. 80120 Warehouse & Service Center: 121 Southpointe Drive, Bridgeville, PA. 15017...

Need help?

Do you have a question about the MBS 4 and is the answer not in the manual?

Questions and answers