Table of Contents

Advertisement

Quick Links

Original operating instructions

© Lutz-Jesco GmbH 2021

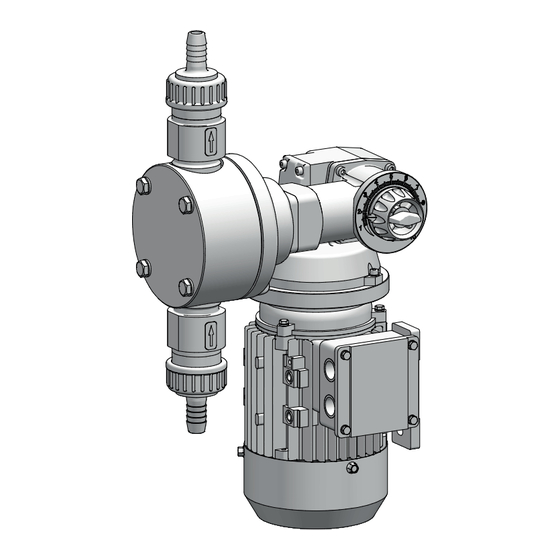

Bild BA Titelbild

Mididos C 120

10302343_3

Read the operating manual!

The user is responsible for installation and operation related mistakes!

BA-10303-02-V01

Diaphragm dosing pump

MIDIDOS C

Operating instructions

Dosing

Liquids

Conveying

Gases

Control

Systems

Advertisement

Table of Contents

Summary of Contents for Lutz-Jesco MIDIDOS C

- Page 1 Bild BA Titelbild Diaphragm dosing pump Mididos C 120 10302343_3 MIDIDOS C Operating instructions Read the operating manual! The user is responsible for installation and operation related mistakes! Dosing Original operating instructions BA-10303-02-V01 Liquids Conveying Gases © Lutz-Jesco GmbH 2021...

-

Page 3: Table Of Contents

2.4 Personal protective equipment ............. 15 Delivery characteristic curves .........27 2.5 Personnel qualification ..............3 Intended use ..............8 16 EU declaration of conformity MIDIDOS C ......28 3.1 Notes on product warranty ............17 Declaration of no objection ..........29 3.2 Intended purpose ................. -

Page 4: Notes For The Reader

1 Notes for the Reader 1.3 Explanation of the warning signs These Operating instructions contain information and behaviour rules for safe and designated operation of the dosing pump MIDIDOS C. Warning signs represent the type and source of a danger: Observe the following principles:... -

Page 5: Safety

Diaphragm dosing pump MIDIDOS C Operating instructions 2 Safety 2.1 General warnings WARNING The following warnings are intended to help you to eliminate the dangers Caustic burns or other burns through dosing media! that can arise while handling the dosing pump. Risk prevention measures always apply regardless of any specific action. -

Page 6: Working In A Safety-Conscious Manner

Diaphragm dosing pump MIDIDOS C Operating instructions 2.3 Working in a safety-conscious manner 2.5 Personnel qualification Besides the safety instructions specified in this operating manual, further Any personnel who work on the dosing pump must have appropriate spe- safety rules apply and must be followed: cial knowledge and skills. - Page 7 Diaphragm dosing pump MIDIDOS C Operating instructions 2.5.4 Trained persons Trained persons have received training from the operator about the tasks they are to perform and about the dangers stemming from improper be- haviour. In the table below you can check what qualifications are the pre-condi- tion for the respective tasks.

-

Page 8: Intended Use

3.2 Intended purpose 3.5 Foreseeable misuse The dosing pump MIDIDOS C is intended for the following purpose: the Below, there is information about the applications of the dosing pump or conveying and dosing of liquids. associated equipment that are not considered to be intended use. This section is intended to allow you to detect possible misuse in advance and 3.3 Principles... - Page 9 Diaphragm dosing pump MIDIDOS C Operating instructions 3.5.2 Incorrect hydraulic installation 3.5.6 Incorrect maintenance Suction and pressure lines dimensioned incorrectly Carrying out maintenance during ongoing operation Unsuitable connection of the pipes due to wrong material or unsuita- Carrying out work that is not described in the operating manual...

-

Page 10: Product Description

A constant volume per stroke or time is delivered. MIDIDOS C is a conventional diaphragm dosing pump designed for the The system delivers or meters the dosing medium by means of a repeat- targeted addition of chemicals. -

Page 11: Technical Data

Diaphragm dosing pump MIDIDOS C Operating instructions 5 Technical data Please note that some of this data only represents guide values. The actual capacity of a dosing pump depends on various factors. For approximate val- ues of the delivery capacity at different pressures, refer to chapter “15 Delivery characteristic curves” on page 27. -

Page 12: Other Data

Details Membrane diameter Nominal size of the double ball valves DN10 Protection class IP55 Tab. 10: Other data MIDIDOS C 5.4 Motor data The motor data is specified on the motor identification plate. Technical data BA-10303-02-V01 © Lutz-Jesco GmbH 2021... -

Page 13: Dimensions

Diaphragm dosing pump MIDIDOS C Operating instructions 6 Dimensions All dimensions in mm The dimensions in brackets apply to the MIDIDOS C 120. ~ 220 (~ 246) ~190 (~208 ) ~180 Ø7 Fig. 3: Dimensional drawing MIDIDOS C Dimensions © Lutz-Jesco GmbH 2021 BA-10303-02-V01 Subject to technical changes. -

Page 14: Installation

Diaphragm dosing pump MIDIDOS C Operating instructions 7 Installation The system piping must not exert any force on the connections and DANGER valves of the dosing pump. To avoid dosing errors at the end of the process, the dosing pump Mortal danger from electric shock! must be locked electrically and hydraulically. -

Page 15: Hydraulic Installations

If you use hazardous dosing media, the installation must be designed tions that the dosing pump MIDIDOS C offers, to guarantee functional such that no disproportionately high consequential damages arise safety or to achieve a high level of dosing precision. -

Page 16: Connecting A Leakage Drain

Fig. 6: Install leakage drain and protects the system in this way from damage caused by over-pres- Lutz-Jesco GmbH dosing pumps are produced to the highest of quality sure. standards with a long service life. However, some parts are subject to op- Notes on assembly: erational wear. - Page 17 Diaphragm dosing pump MIDIDOS C Operating instructions 8.5.3 Back-pressure valve With highly dense dosing media At priming for the first time due to dry valves and air in the suction line Back-pressure control valves are necessary if: and the dosing head...

-

Page 18: Electrical Installation

Diaphragm dosing pump MIDIDOS C Operating instructions 9 Electrical installation 9.1 Circuit diagrams of the drive motor DANGER Three-phase motors Mortal danger from electric shock! Y-connection Delta connection If there is an electrical accident, you must disconnect the dosing pump from the mains as quickly as possible. -

Page 19: Control

Mididos C 120 10302343_7 Diaphragm dosing pump MIDIDOS C Operating instructions 10 Control Stroke length adjustment The desired delivery rate of the dosing pump is set using the stroke length adjustment. The Turning the adjustment knob adjusts the hub length and so increases or decreases the amount of dosing media from the dosing head. -

Page 20: Operation

Diaphragm dosing pump MIDIDOS C Operating instructions 11 Operation 11.1 Start-up WARNING WARNING Caustic burns or other burns through dosing media! Chemical may spray out. This may lead to chemical or other burns. Caustic burns or other burns through dosing media! ð... -

Page 21: Shutting Down In An Emergency

Diaphragm dosing pump MIDIDOS C Operating instructions 11.6 Disposal of old equipment ü Comply with the valid accident prevention regulations. The waste unit must be thoroughly cleaned. Any dangerous dosing Perform the following working steps: media must be additionally neutralised and decontaminated. -

Page 22: Maintenance

Operating instructions 12 Maintenance 12.1 Maintenance intervals Dosing pumps by Lutz-Jesco are manufactured to the highest quality standards and have a long service life. Nevertheless, some of their parts are subject to wear due to operation (e.g. diaphragms, valve seats, valve This table gives you an overview of maintenance work and the intervals balls). -

Page 23: Lubrication

Only use the greases specified in this section for lubrication. 12.3.3 Install a new diaphragm The MIDIDOS C diaphragm dosing pump is designed to be easy to main- PLEASE NOTE tain. The pump gearbox is lifetime lubricated with a molybdenum disul- phite lubricant. - Page 24 Diaphragm dosing pump MIDIDOS C Operating instructions Suction and pressure valves differ in the sequence of assem- bly of the individual parts. Disassemble them one at a time to prevent parts being mixed up. Finally, screw the valves at first finger-tight into the dosing head. While doing this, ensure that the seals or O-rings are correctly seated inside the valves and the dosing head.

- Page 25 Diaphragm dosing pump MIDIDOS C Operating instructions 13 Troubleshooting See below for information about how to rectify faults on the device or the system. If you cannot eliminate the fault, please consult with the manu- facturer on further measures or return the dosing pump for repair.

- Page 26 14 Spare parts Only use original spare parts supplied by the manufacturer. The wearing parts for MIDIDOS C are available as a spare parts set. Dosing heads and spare parts are available in various materi- als and material combinations. Further information is available from the manufacturer.

- Page 27 Krischke MIDIDOS C 24 Stroke length 2 bar 10 bar MIDIDOS C 72 Stroke length Fig. 9: Delivery characteristic curves MIDIDOS C 2 bar 6 bar MIDIDOS C 48 Stroke length Delivery characteristic curves © Lutz-Jesco GmbH 2021 BA-10303-02-V01 Subject to technical changes.

- Page 28 Diaphragm dosing pump MIDIDOS C Operating instructions 16 EU declaration of conformity MIDIDOS C (DE) EU-Konformitätserklärung Hiermit erklären wir, dass das nachfolgend bezeichnete Gerät aufgrund seiner Konzipierung und Bauart sowie in der von uns in Verkehr gebrachten Ausführung den einschlägigen grundlegenden Sicherheits- und Gesundheitsanforderungen der aufgeführten EG-Richtlinien entspricht. Bei einer nicht mit uns abgestimmten Änderung am Gerät verliert diese Erklärung ihre Gültigkeit.

- Page 29 Diaphragm dosing pump MIDIDOS C Operating instructions 17 Declaration of no objection Declaration of no objection Please fill out a separate form for each appliance! We forward the following device for repairs: Device and device type: ..............Part-no.:................... Order No.:..................

- Page 30 Diaphragm dosing pump MIDIDOS C Operating instructions 18 Warranty claim Warranty claim Please copy and send it back with the unit! If the device breaks down within the period of warranty, please return it in a cleaned condition with the complete warranty claim.

- Page 31 Diaphragm dosing pump MIDIDOS C Operating instructions 19 Index Accessories ..................16 Rating plate ..................10 Approved media temperature ............12 Safety ....................5 Back-pressure valve ................17 Scope of delivery ................10 Shutting down in an emergency ............21 Signal words Explanation ...................4 Clean suction and pressure valves ...........23 Spare parts ..................26...

- Page 32 Bild BA Titelbild Mididos C 120 10302343_3 Lutz-Jesco GmbH Am Bostelberge 19 D-30900 Wedemark Phone: +49 5130 5802-0 info@lutz-jesco.com www.lutz-jesco.com Operating instructions MIDIDOS C...

Need help?

Do you have a question about the MIDIDOS C and is the answer not in the manual?

Questions and answers