Summary of Contents for WAGNER T0180.00A

- Page 1 Translation of the Original Operating Manual Version 05 / 2013 Pressure Regulator for Paint...

-

Page 3: Table Of Contents

Safety Instructions for the Operator 4.1.1 Electrical Equipment 4.1.2 Staff Qualifi cations 4.1.3 Safe Work Environment Safety Instructions for Staff 4.2.1 Safe Handling of WAGNER Spray Devices 4.2.2 Grounding the Unit 4.2.3 Material Hoses 4.2.4 Cleaning 4.2.5 Handling Hazardous Liquids, Varnishes, and Paints 4.2.6... - Page 4 T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL Contents Mode of Operation 5.4.1 Pressure Regulator ASSEMBLY AND COMMISSIONING Transportation Storage Assembly Grounding Commissioning 6.5.1 Safety Instructions 6.5.2 Basic Flushing 6.5.3 Pressure Relief 6.5.4 Pressure Tightness Test OPERATION...

-

Page 5: About This Operating Manual

T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL ABOUT THIS OPERATING MANUAL PREFACE The operating manual contains information about safely operating, maintaining, cleaning and repairing the device. The operating manual is part of the device and must be available to operating and service staff . -

Page 6: Languages

T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL LANGUAGES The operating manual is available in the following languages: Language: Order No. Language: Order No. German 2338923 English 2338925 Italian 2338928 French 2338926 Spanish 2338929 ABBREVIATIONS IN THE TEXT... -

Page 7: Correct Use

T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL CORRECT USE DEVICE TYPES Pressure regulator for paint with order no. TYPE OF USE The device is suitable for processing liquid materials such as paints and varnishes in accordance with their classifi cation into explosion classes IIA or IIB. -

Page 8: Safety Parameters

OPERATING MANUAL SAFETY PARAMETERS WAGNER accepts no liability for any damage arising from incorrect use. Use the device only to work with the materials recommended by WAGNER. Only operate the device as a whole. Do not deactivate safety fi xtures. -

Page 9: Reasonably Foreseeable Misuse

The forms of misuse listed below may result in health issues and/or material damage: use of powder as a coating material Wagner pressure regulators for paint are not designed for use with food. RESIDUAL RISKS Residual risks are risks which cannot be excluded even in the event of correct use. -

Page 10: Identification

T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL IDENTIFICATION EXPLOSION PROTECTION IDENTIFICATION Pressure regulator for paint with order no. As defi ned in Directive 94/9/EC (ATEX 95), the device is suitable for use in areas where there is an explosion hazard. -

Page 11: General Safety Instructions

T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL GENERAL SAFETY INSTRUCTIONS SAFETY INSTRUCTIONS FOR THE OPERATOR Keep this operating manual at hand near the unit at all times. Always follow local regulations concerning occupational safety and accident prevention. -

Page 12: Safety Instructions For Staff

The liquid emitters are to be checked for safe working conditions by an expert (e.g. Wagner Service Technician) as often as necessary or at least every 12 months, in accordance with the guidelines for liquid emitters (ZH 1/406 and BGR 500 Part 2 Chapter 2.36). -

Page 13: Material Hoses

T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL 4.2.3 MATERIAL HOSES Ensure that the hose material is chemically resistant to the sprayed materials. Ensure that the material hose is suitable for the pressure generated in the device. -

Page 14: Touching Hot Surfaces

T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL 4.2.6 TOUCHING HOT SURFACES Only touch hot surfaces if you are wearing protective gloves. When operating the unit with a coating material with a temperature of > 43 °C; 109.4 °F: - Identify the device with a warning label "Warning - hot surface". -

Page 15: Tightness Check

4.3.1 SAFETY REGULATIONS Safe handling of WAGNER spray devices Mechanical sparks can form if the device comes into contact with metal. In an explosive atmosphere: Do not knock or push the unit against steel or rusty iron. -

Page 16: Operation Without Fluid

T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL Cleaning If there are deposits on the surfaces, the device may form electrostatic charges. Flames or sparks can form during discharge. Remove deposits from the surfaces to maintain conductivity. -

Page 17: Description

T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL DESCRIPTION AREAS OF APPLICATION NOTICE Abrasive materials and pigments! Greater wear of parts carrying the material. Use the application-oriented model as indicated in Chapter 5.3.2. Check if the fl uids and solvents used are compatible with the construction materials as indicated in Chapter 5.3.1. -

Page 18: Technical Data

T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL 5.3.2 TECHNICAL DATA Description Unit Material temperature °C +4 ÷ 40 +4 ÷ 40 °F +39 ÷ 104 +39 ÷ 104 Ambient temperature °C +4 ÷ 40 +4 ÷ 40 °F... -

Page 19: Mode Of Operation

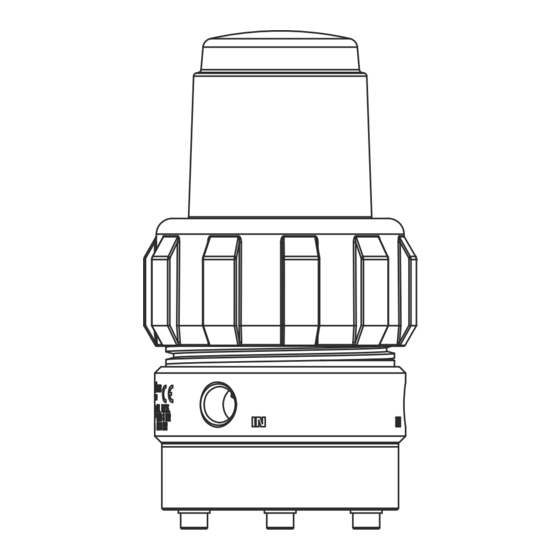

T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL MODE OF OPERATION 5.4.1 PRESSURE REGULATOR 1 Filter 2 Control air inlet 1:1 3 Diaphragm a Valve ball and seat P1 Material outlet/ manometer P2 Material inlet Description of the unit The pressure regulator is usually used in paint application systems in order to control the pressure of the medium on the device to which it is connected. -

Page 20: Assembly And Commissioning

Discharge of electrostatically charged components in atmospheres containing solvents! Explosion hazard from electrostatic sparks. Only use a damp cloth to clean the device. ASSEMBLY WAGNER pressure regulators must be installed and maintained in compliance with the system maintenance regulations for explosive atmospheres. B_04152... - Page 21 T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL 1. If necessary, threaded connections must be secured as appropriate. 2. Ensure that the direction of fl ow of the medium accords with the information on the housing of the pressure regulator.

-

Page 22: Grounding

T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL GROUNDING WARNING Discharge of electrostatically charged components in atmospheres containing solvents! Explosion hazard from electrostatic sparks. Only use a damp cloth to clean the device. WARNING Heavy paint mist if grounding is insuffi cient! Danger of poisoning. -

Page 23: Commissioning

T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL COMMISSIONING 6.5.1 SAFETY INSTRUCTIONS Before carrying out any work, the following points must be observed in accordance with the operating manual: - Observe all safety regulations in accordance with Chapter 4. -

Page 24: Basic Flushing

T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL 6.5.2 BASIC FLUSHING The pressure regulator was tested with oil. We recommend fl ushing the pressure regulator with an appropriate solvent before using it to remove traces of oil and deposits from manufacture. -

Page 25: Operation

T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL OPERATION REGULATING THE PRESSURE OF THE MEDIUM The pressure regulator controls the pressure of the medium which comes from the pressure regulator. In order for the unit to function without any problems, the pressure of the incoming medium must be higher than the pressure at the outlet. -

Page 26: Cleaning And Decommissioning

T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL CLEANING AND DECOMMISSIONING 7.2.1 FLUSHING Flush the unit when the color or product is changed, at the end of the working day where necessary, before shutting the system down and before repairs are carried out. -

Page 27: Trouble Shooting And Rectification

Leak (medium Diaphragm torn. Replace diaphragm. escaping) from regulator housing or medium sucked back into control section If none of the causes of malfunction mentioned are present, the defect can be remedied by a WAGNER Service Center. -

Page 28: Cleaning And Maintenance

In accordance with the guideline for liquid emitters (ZH 1/406 and BGR 500 Part 2 Chapter 2.36): - The liquid emitters should be checked by an expert (e.g. Wagner service technician) for their safe working conditions as required and at least every 12 months. -

Page 29: Safety Instructions

T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL SAFETY INSTRUCTIONS Prior to maintenance and cleaning measures note: Wear protective clothing and use specifi c protection devices with regard to the nature of the fl uids involved. Provide the correct tools. -

Page 30: Cleaning The Pressure Regulator

T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL CLEANING THE PRESSURE REGULATOR Regular cleaning and inspection of internal parts are essential for the optimum function of the pressure regulator. 1. Release the compressed air and the control air (if present) and depressurize the medium. -

Page 31: Material Hoses

T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL MATERIAL HOSES The service life of the fl uid hoses is reduced due to environmental infl uences even when handled correctly. Check hoses, pipes, and couplings every day and replace if necessary. -

Page 32: Accessories

T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL ACCESSORIES 10.1 ACCESSORIES Filter cartridges with mesh 60 and 150 are listed in Chapter 11. -

Page 33: Spare Parts

Incorrect maintenance/repair! Risk of injury and equipment damage. Have repairs and part replacements carried out only by specially trained staff or a WAGNER service center. Before all work on the device and in the event of work interruptions: - Switch off the energy/compressed air supply. -

Page 34: Fine Flow Controller

T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL 11.2 FINE FLOW CONTROLLER 40 Nm 5 Nm 6 Nm B_04154... - Page 35 T0180.00A VERSION 05 / 2013 ORDER NUMBER DOC 2338925 OPERATING MANUAL Fine Flow Controller Order No. Order No. Designation T0180.00A T0180.00AI Fine Flow Controller, 14/0.5-8 bar A588.03 A588.03 Diaphragm disc - material side A590.03 A590.03 Diaphragm disc - air side B0172.03...

-

Page 36: Guarantee And Conformity Declarations

The manufacturer will not be held liable or will only be held partially liable if third-party accessories or spare parts have been used. With genuine WAGNER accessories and spare parts, you have the guarantee that all safety regulations are complied with. -

Page 37: Ce Declaration Of Conformity

II 2G IIB T5 EC Certifi cate of Conformity The CE certifi cate of conformity is enclosed with this product. If needed, further copies can be ordered through your WAGNER dealer by specifying the product name and serial number. Order number:... - Page 38 Telephone: +41 (0)71 757 2211 Telefax: +49 7544 505200 Telefax: +41 (0)71 757 2222 E-Mail: service.standard@wagner-group.com E-Mail: rep-ch@wagner-group.ch Belgium Denmark WAGNER Spraytech Benelux BV WAGNER Industrial Solution Scandinavia Veilinglaan 58 Viborgvej 100, Skærgær B- 1861 Wolvertem DK- 8600 Silkeborg Telephone: +32 (0)2 269 4675...

- Page 40 Order No. 2338925 People's Republic of China Phone Germany Phone E-mail...

Need help?

Do you have a question about the T0180.00A and is the answer not in the manual?

Questions and answers