Summary of Contents for WAGNER T090

- Page 1 Translation of the original Operating Manual Paint Pressure Regulators T090, T092 Edition 01 / 2014 Paint Pressure Regulators T090, T092 II 2G IIB T5...

-

Page 3: Table Of Contents

Safety instructions for the operator 2.1.1 Electrical equipment 2.1.2 Personnel qualifi cations 2.1.3 A safe work environment Safety instructions for staff 2.2.1 Safe handling of WAGNER spray units 2.2.2 Earth the unit 2.2.3 Material hoses 2.2.4 Cleaning 2.2.5 Handling hazardous liquids, varnishes and paints 2.2.6... - Page 4 Storing for longer periods of time FAULT LOCATION, MAINTENANCE AND REPAIR Trouble shooting and solution Maintenance SPARE PARTS How to order spare parts Exploded views 7.2.1 T090.00A - T090.00B - T090.00C 7.2.2 T090.00CR 7.2.3 T090.00MAG 7.2.4 T092.00AI - T092.00BI 7.2.5...

-

Page 5: About These Instructions

T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL ABOUT THESE INSTRUCTIONS LANGUAGES ZZB022GER ZZB022ENG ZZB022FRE ZZB022ITA ZZB022SPA WARNINGS, NOTES AND SYMBOLS IN THESE INSTRUCTIONS... -

Page 6: General Safety Instructions

T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL GENERAL SAFETY INSTRUCTIONS SAFETY INSTRUCTIONS FOR THE OPERATOR 2.1.1 ELECTRICAL EQUIPMENT 2.1.2 PERSONNEL QUALIFICATIONS 2.1.3 A SAFE WORK ENVIRONMENT Ensure that the floor of the working area is anti-static in accordance with EN 50053 Part 1 §7-2. -

Page 7: Safe Handling Of Wagner Spray Units

EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL 2.2.1 SAFE HANDLING OF WAGNER SPRAY UNITS The spray jet is under pressure and can cause dangerous injuries. Avoid injection of paint or cleaning agents: Never point the spray gun at people. -

Page 8: Cleaning

T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL 2.2.4 CLEANING 2.2.5 HANDLING HAZARDOUS LIQUIDS, VARNISHES AND PAINTS 2.2.6 TOUCHING HOT SURFACES CORRECT USE... -

Page 9: Use In An Explosion Hazard Area

T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL Check the equipment periodically. Repair or replace worn or damaged parts immediately. Do not exceed the maximum allowed pressure. Refer to technical data section. Use the equipment only with fluids and solvents that are chemically compatible with the equipment‘s wetted parts. - Page 10 T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL Never use chlorinated and halogenated solvents (for ex. Trichloroethane and Methylene chloride) with equipment containing aluminium or having galvanised and zinced parts, since they could react chemically with serious risks of explosion. Read the classifi cation sheet and all information referring to the product and solvent that are going to be used and ask for the manufacturer’s advice in case of doubts.

-

Page 11: Product Liability And Warranty

T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL PRODUCT LIABILITY AND WARRANTY IMPORTANT NOTES ON PRODUCT LIABILITY WARRANTY... -

Page 12: Ce-Conformity

T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL CE-CONFORMITY Herewith we declare that the supplied version of: Pressure regulators with article no. T090.00A T090.00B T090.00C T090.00CR T090.00MAG T092.00AI T092.00BI T092.00PNI Complies with the following provisons applying to it:... -

Page 13: Description

T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL DESCRIPTION FIELD OF APPLICATION 4.1.1 USING IN ACCORDANCE WITH THE INSTRUCTIONS The pressure regulator is suitable for working with liquid materials. CAUTION Abrasive fluids and pigments ! Greater wear of the parts carrying the material. -

Page 14: Technical Data

T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL 4.3.2 TECHNICAL DATA Description Units T090.00A T090.00B T090.00C Max allowed fl uid temperature °C 60° 60° 60° Max inlet pressure 4351 4351 4351 Adjustment range 1 ÷ 6 3 ÷ 12 4 ÷... - Page 15 T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL Description Units T092.00BI T092.00AI Max allowed fl uid temperature °C 60° 60° Max inlet pressure 4351 4351 Adjustment range 3 ÷ 12 1 ÷ 6 30 ÷ 120 10 ÷ 60 435 ÷...

-

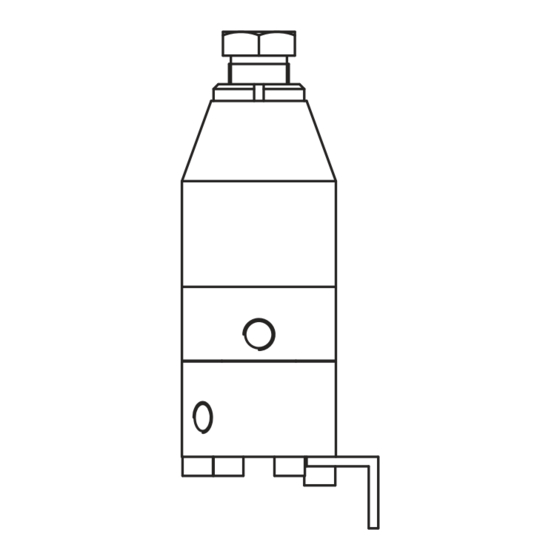

Page 16: Functioning

Regulation spring Regulation knob P1 Fluid outlet / pressure gauge P2 Fluid inlet Fig. 1 (T090.00A, B, C, CR, MAG) Fig. 2 (T092.00AI, BI) Fig. 3 (T092.00PNI) General description The fl uid pressure regulator is normally used in the painting systems to assure a good fl uid pressure control to the equipment. - Page 17 T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL The regulation device is composed of a spring (b) loaded by a screw with knob (c) and works through a piston (2) or the diaphragm (1) on the adjusting ball valve (a). The pressure exerted by the spring on the piston (2) or on the adjusting diaphragm (3) is counterbalanced by the fl uid outlet pressure (P1).

-

Page 18: Starting Up And Operating

INSTALLATION AND CONNECTION 5.1.1 INSTALLATION PRESSURE REGULATOR Warning WAGNER Colora Srl pressure regulators shall be installed and maintained in compliance with the maintenance regulations provided for environments classifi ed against explosion risk for the presence of Gas EN 60079-14, EN 60079-17. -

Page 19: Earthing

T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL 5.1.2 EARTHING The regulator base shall be put to earth by means of the contact with the supporting brackets, frames or fl uid manifolds. Make sure to avoid electrostatic charges on connecting pipes, using pipes in conductive material where necessary. -

Page 20: Start Up

T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL START UP 5.2.1 SAFETY REGULATIONS Every time before starting up the following points should be observed as laid down in the operating instructions: - That it is possible to observe the safety regulations in Chap. 2. -

Page 21: Cleaning

T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL 5.2.2 CLEANING Pressure regulator has been tested with oil. Before using it, it is advisable to clean it by pumping an adequate solvent to remove all residues of this liquid or other residues that could have entered during the assembling phase. -

Page 22: Pressure Discharge Procedure

T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL 5.2.3 PRESSURE DISCHARGE PROCEDURE Always discharge pressure in case of stop, maintenance or check of any equipment of the circuit being fed by the pressure reducer as well as in case of installation or cleaning of a nozzle. - Page 23 T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL...

-

Page 24: Finishing Work And Cleaning

T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL FINISHING WORK AND CLEANING 5.3.1 WASHING Wash before any product or colour change and at the end of the working day if necessary; wash before any stop of the equipment and before carrying out any maintenance operation. -

Page 25: Fault Location, Maintenance And Repair

1. Check and clean the fi lter every day or as required. 2. Check and replace if necessary hoses, tubes, couplings every days. WAGNER recommends to check the whole spray system every year from a technical expert (e.g. WAGNER service technician). -

Page 26: Spare Parts

T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL SPARE PARTS HOW TO ORDER SPARE PARTS... - Page 27 T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL...

-

Page 28: Exploded Views

T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL EXPLODED VIEWS 7.2.1 T090.00A - T090.00B - T090.00C T090.00A 1 x 23=23 T090.00B 2 x 13=26 T090.00C 3 x 9=27 15 (35 Nm) C_00195 d 7 mm 50 mm 65 mm... - Page 29 T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL Spare parts list T090.00A T090.00B T090.00C Description Q.ty Lower reducer body B589.22 Main reducer body B590.22 Upper reducer body B591.22 Ball seat T6044.00 Adjustment screw B594.03 Shutter piston B595.53 ...

-

Page 30: T090.00Cr

T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL 7.2.2 T090.00CR 3 x 9=27 17 (35 Nm) C_00196 d 7 mm 50 mm 65 mm... - Page 31 T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL Spare parts list T090.00CR Description Q.ty Lower reducer body B589.22 Main reducer body B590.22 Upper reducer body B591.22 Ball seat K069.04 Adjustment screw B594.03 Shutter piston B595.53 Shutter stem B0253.03...

-

Page 32: T090.00Mag

T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL 7.2.3 T090.00MAG 1 x 25=25 8 (35 Nm) C_00197 d 7 mm 50 mm 65 mm... - Page 33 T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL Spare parts list T090.00MAG Description Q.ty Lower reducer body B0252.22 Main reducer body B590.22 Upper reducer body B591.22 Ball seat T6044.00A Adjustment screw B594.03 Shutter piston B595.53 Shutter stem B0253.03...

-

Page 34: T092.00Ai - T092.00Bi

T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL 7.2.4 T092.00AI - T092.00BI T092.00AI 1 x 24=24 T092.00BI 2 x 14=28 d 7 mm 50 mm 65 mm 35 Nm 35 Nm C_00189... - Page 35 T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL Spare parts list T092.00AI T092.00BI Description Q.ty Q.ty Lower reducer body B640.03A B640.03A Ball guide B637.03 B637.03 Spring H261.03 H261.03 Carbide D5 ball K828.04 K828.04 EPDM O-ring L130.06...

-

Page 36: T092.00Pni

T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL 7.2.5 T092.00PNI 15 Nm 35 Nm C_00190... - Page 37 T090, T092 EDITION 01 /2014 PART NO. ZZB022ENG OPERATING MANUAL Spare parts list T092.00PNI Description Q.ty Lower reducer body B640.03A Ball guide B637.03 Spring H261.03 Carbide D5 ball K828.04 EPDM O-ring L130.06 Complete ball seat body T6008.00...

- Page 38 Telefax: ++49/ (0)7544 / 505200 Telefax: ++41/ (0)71 / 757 2222 E-Mail:service.standard@wagner-group.com E-Mail: rep-ch@wagner-group.ch Belgium Denmark WAGNER Spraytech Benelux BV WAGNER Spraytech Scandinavia A/S Veilinglaan 56 Kornmarksvej 26 B- 1861 Wolvertem DK- 2605 Brøndby Telephone: ++32/ (0)2 / 269 4675...

- Page 40 ZZB022ENG...

Need help?

Do you have a question about the T090 and is the answer not in the manual?

Questions and answers